27

221992D

10 Replacement of Parts

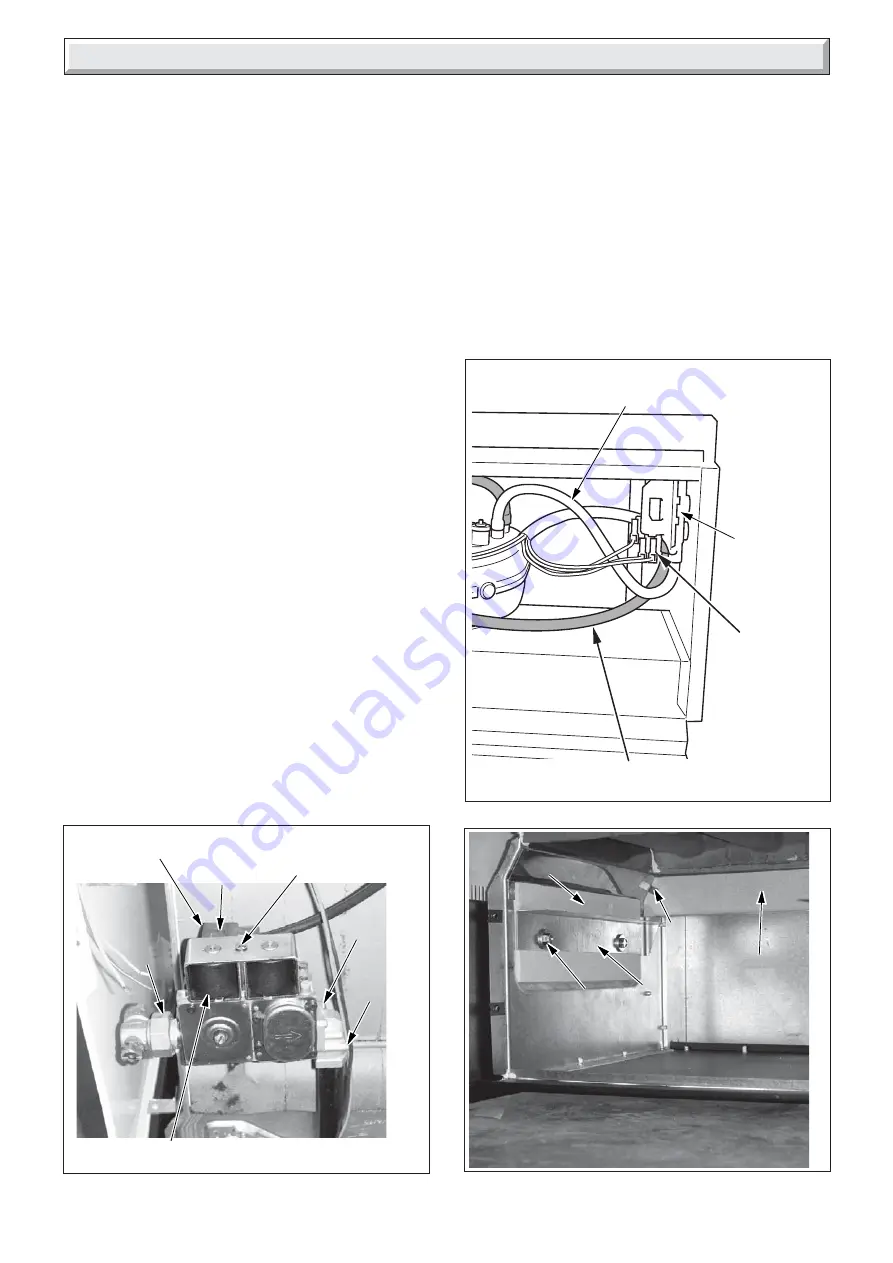

Diagram 10.6

REAR

INSULATION

PANEL

SECURING

NIB

SIDE

INSULATION

0000

Diagram 10.4

GAS

SERVICE

COCK

UNION

ELECTRICAL

PLUG

SHORT

SCREWS (2)

LONG

SCREWS

(2)

SOLENOID

SECURING SCREW

SOLENOID ASSEMBLY

BURNER

SUPPORT

BRACKET

NUTS

10.5 Solenoid

Remove the electrical plug from the multifunctional control and

remove the securing screw and then the solenoid assembly,

see diagram 10.4.

10.6 Burner

Refer to the relevant paragraphs of the servicing section to

remove the burner from combustion chamber.

10.7 Injector

Refer to the relevant paragraphs of the servicing section to

remove the burner from combustion chamber.

The injector can then be unscrewed from the manifold.

When replacing use a little jointing compound on the external

thread only, to ensure a gas tight seal.

10.8 Air Pressure Switch

Remove front panel to gain access, see section 6.8.

Refer to the relevant paragraphs of the servicing section to

remove the burner from combustion chamber.

Remove the air pressure tubes and electrical connections from

the switch, release the securing screws and remove the switch,

see diagram 10.5.

When fitting the replacement make sure that the air pressure

tubes are fitted with the clear tube from the air pressure switch

to the front fan connection, as shown in diagram 10.5 and the

electrical connections are made as shown in wiring diagram

9.4.

10.9 Fan

Remove front panel to gain access, see section 6.8.

Refer to the relevant paragraphs of the servicing section to

remove the burner from combustion chamber.

Remove the electrical connections and air pressure tubes from

the fan.

Note: Remove the electrical connections by pulling insulation

boots only.

Undo the screw securing the fan to the flue hood and disengage

fan from flue hood.

When re-assembling, make sure that the air pressure tubes are

fitted as before and that the fan duct engages fully into the flue

duct extension piece.

The polarity of the electrical connections is not important.

SECURING

SCREW

Diagram 10.5

10259

FRONT AIR PRESSURE

SWITCH TUBE (CLEAR)

AIR

PRESSURE

SWITCH

ELECTRICAL

CONNECTORS

REAR AIR PRESSURE

SWITCH TUBE (RED)

10.10 Insulation

Refer to the relevant paragraphs of the servicing section to

remove the burner from combustion chamber.

Sides

Undo the burner support bracket nuts and remove support

bracket and insulation, see diagram 10.6.

Refit support bracket with new side insulation.

Rear

Bend forward rear insulation securing nibs, one on each side,

to release insulation.

Fit new insulation and bend back securing nibs.