Supplied By www.heating spares.co Tel. 0161 620 6677

10

3.3

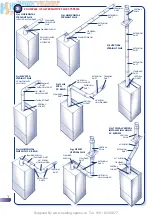

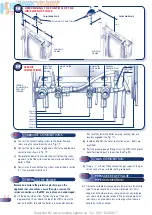

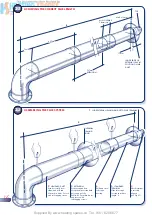

FLUE TERMINAL POSITION

Detailed recommendations for flue installation are given in

BS 5440:1. The following notes are for general guidance.

a)

The boiler MUST be installed so that the terminal is exposed to

the external air.

b)

It is important that the position of the terminal allows free

passage of air across it at all times.

c)

It is ESSENTIAL TO ENSURE that products of combustion

discharging from the terminal cannot re-enter the building, or

any other adjacent building, through ventilators, windows,

doors, other sources of natural air infiltration, or forced

ventilation / air conditioning.

d)

The minimum acceptable dimensions from the terminal to

obstructions and ventilation openings are specified in Fig.12.

e)

If the terminal discharges into a pathway or passageway

check that combustion products will not cause nuisance and

that the terminal will not obstruct the passageway.

f)

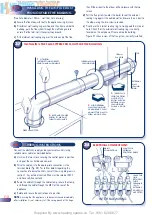

Where the lowest part of the terminal is fitted less than 2m

(78ins) above ground, above a balcony or above a flat roof to

which people have access, the terminal MUST be protected by

a purpose designed guard. (Available as an optional extra)

g)

Where the terminal is fitted within 850mm (34in) of a plastic

or painted gutter, or 450mm (18in) of painted eaves, an

aluminium shield at least 750mm long must be fitted to the

underside of the painted surface.

h)

The air inlet / flue outlet duct MUST NOT be closer than

25mm (1in) to combustible material.

i)

In certain weather conditions the terminal may emit a plume

of steam. This is normal but positions where this would cause

a nuisance should be avoided.

Detailed recommendations for air supply are given in BS 5440:2.

The following notes are for general guidance.

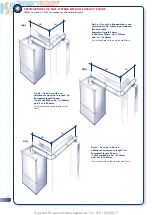

a)

It is not necessary to have a purpose provided air vent in the

room or internal space in which the appliance is installed.

b)

If the boiler is to be installed in a wall cupboard permanent air

vents are required for cooling purposes in the cupboard at both

high and low levels. Both air vents must communicate with either

the same internal room / space or be on the same wall to

external air. Each air vent communicating with another room or

internal space must have a minimum effective area of:

Finest - 298cm

2

(46in

2

)

Finest Gold - 337cm

2

(52in

2

)

If the ventilation is direct to air from outside the building, the

necessary areas quoted above may be halved.

If the cupboard or compartment is full room height (2.3 m min.)

then NO purpose made ventilation is required.

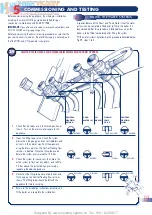

3.5

GAS SUPPLY

a)

The Gas Supplier should be consulted at the installation

planning stage in order to establish the availability of an

adequate supply of gas.

b)

An existing service pipe MUST NOT be used without prior

consultation with the Gas Supplier.

c)

A gas meter can only be connected by the Gas Supplier or by

their contractor.

d)

An existing meter and/or pipework should be of sufficient size

to carry the maximum boiler input plus the demand of any

other installed appliance. (BS 6891: 1988).

A minimum of

22mm dia. pipework is required to within 1 metre of

the appliance gas cock.

e) Natural gas appliances:

The governor at the meter must

give a constant outlet pressure of 20mbar (8 in.wg) when all

appliance’s on the system are running.

Propane appliances:

The regulator must give a constant

outlet pressure of 37 mbar (14.9 in.wg) when all appliance’s

on the system are running.

f)

The gas supply line should be purged. WARNING: Before

purging open all doors and windows, also extinguish any

cigarettes, pipes, and any other naked lights.

g)

The complete installation must be tested for gas soundness .

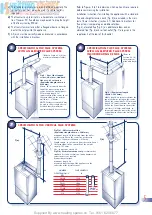

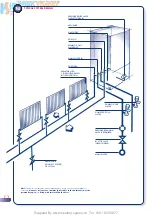

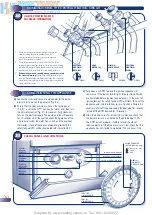

3.6

CENTRAL HEATING SYSTEMS

a)

This appliance is designed for connection to sealed central heat-

ing water systems. Refer to Fig. 15 for a typical system design.

b)

A sealed system must only be filled by a competent person. A

filling loop is supplied as an integral part of the boiler, there-

fore no special connections are needed within the system.

Instructions for filling the system using the integral filling loop

are supplied in section 5.

c)

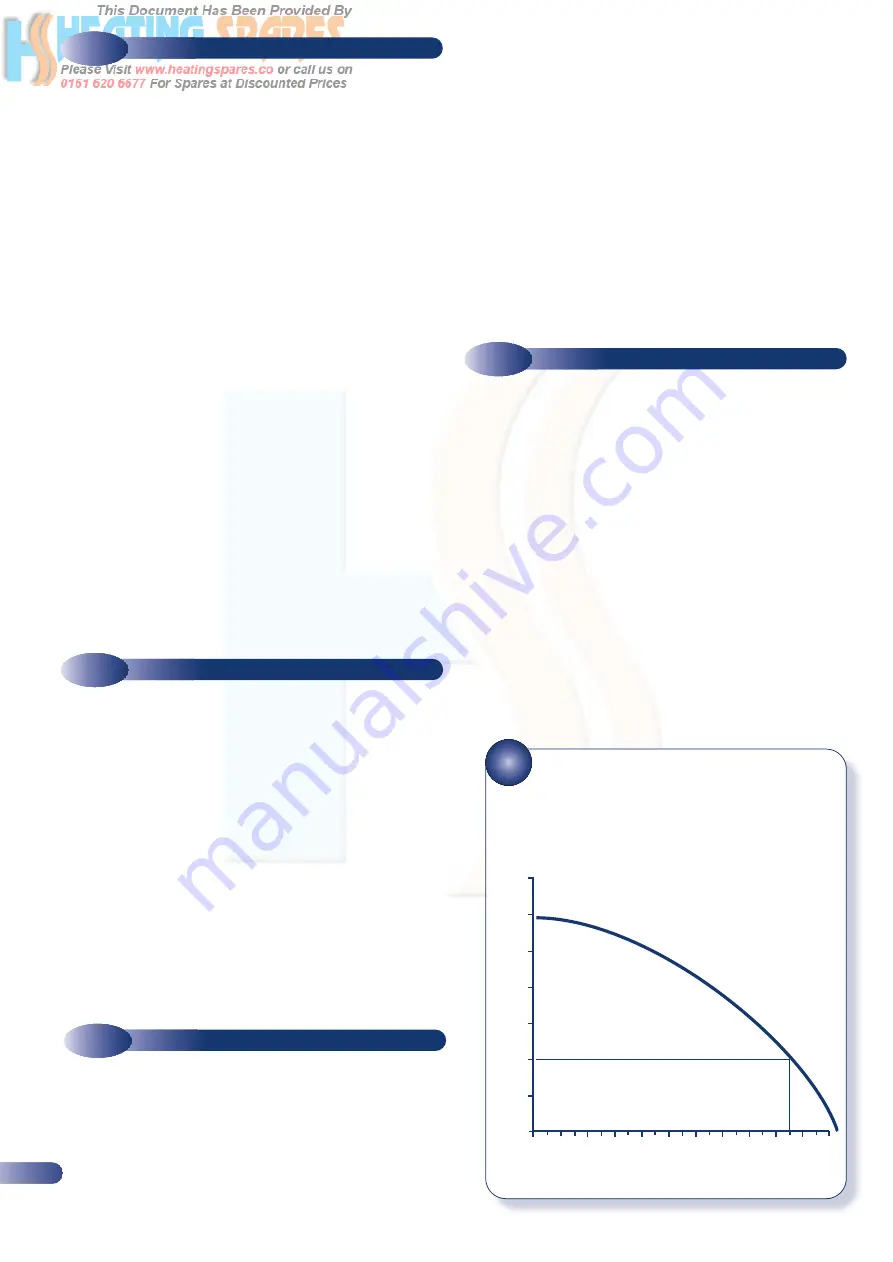

The available pump head is given in Fig. 13.

d)

A minimum heating flow rate corresponding to a heating

differential of 15°C must be obtained at all times.

e)

An automatic heating bypass is fitted within the appliance.

However if thermostatic radiator valves are fitted, a radiator

must be fitted with two lockshield valves.

f)

The following paragraphs outline the specifications of the

items fitted to the boiler.

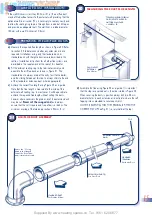

PUMP

The available head shown in Fig. 13 is that in excess of the

appliance hydraulic resistance, i.e. that available for the system.

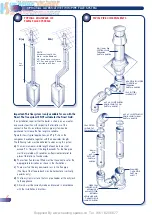

13

AVAILABLE PUMP HEAD

3.4

VENTILATION REQUIREMENTS

0

2

4

6

8

10

12

14

16

18

20

22

7

6

5

4

3

2

1

Flow Rate ltr/min

A

vailable Head Metres

2m HEAD

Bth/hr.

Kw

Flow rate

∆

t°C

80,000

23.45

19l/m

17.7

70,000

20.52

19l/m

15.5

60,000

17.58

19l/m

13.3

50,000

11.72

19l/m

8.8