Supplied By www.heating spares.co Tel. 0161 620 6677

30

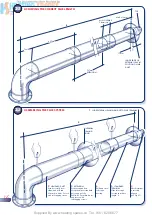

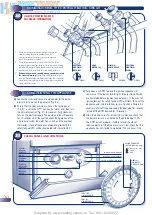

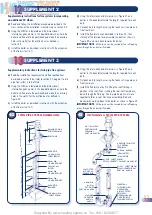

VALVE POSITIONS FOR

NORMAL OPERATION

5.3

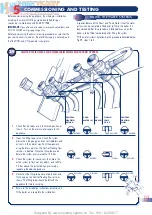

COMMISSIONING THE APPLIANCE

31

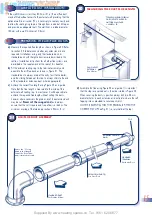

FASCIA PANEL AND CONTROLS

5.2

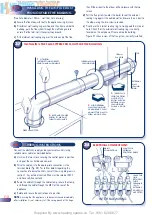

COMMISSIONING THE CENTRAL HEATING CIRCUIT

a)

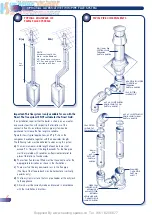

Loosen the screw and connect a manometer to the burner

pressure test point on the gas valve (Fig. 36).

b)

Ensure that the clock override switch on the fascia panel

(Fig. 31) is set to the ‘OFF’ position (hot water only) then turn

the hot water control (Fig. 31) to maximum (fully clockwise).

Turn on the electrical supply. The pump and fan will operate

for 10 seconds whilst the controls check the operation of the

air pressure switch, the water flow switch, and the overheat

thermostat. (If any of these are not operating correctly the

safety lock-out LED will be illuminated refer to section 8.2)

c)

Fully open any DHW tap and the ignition sequence will

commence. If the burner fails to light, three ignition attempts

are completed before ignition lock-out occurs. In the event of

ignition lock-out the safety lock-out LED will flash. To re-set the

appliance and initiate a further series of ignition attempts it is

necessary to turn off the power supply for a period of ten seconds.

(or turn off the DHW demand for 10 seconds).

d)

Allow the boiler to run for at least 10 minutes and check that

the burner pressure is as stated on the data badge ±10%.

The DHW burner pressure is factory set and should not

require adjusting. If the burner pressure is low, check that the

appliance has not started to modulate (This will occur if the

•

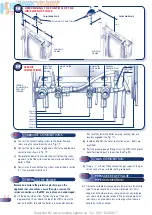

POWER ON LED (GREEN)

•

CENTRAL

HEATING

CONTROL

•

CLOCK

•

OVERRIDE

SWITCH

•

PRESSURE

GAUGE

•

DOMESTIC

HOT WATER

CONTROL

•

BURNER ON LED (AMBER)

•

SAFETY LOCKOUT LED (RED)

•

ARROW

INDICATES

CURRENT TIME

•

TABS OUT

=

ON

PERIOD

•

TABS IN

=

OFF

PERIOD

•

CLOCK OVERRIDE

SWITCH (Heating only)

= Continuous ON

= Timed

= OFF

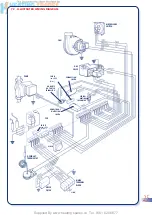

1

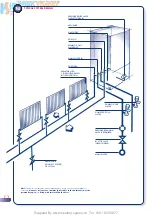

Check that the boiler connections are tight and open the

valves by turning them to the position shown. If it is

necessary to top up the pressure, connect the hose and

repeat the procedure in section 5.1

2

Check the operation of the pressure relief valve (Fig. 33) by

rotating the plastic head anticlockwise 1/4 of a turn and checking

that water is discharged. Ensure that the valve seats correctly and

does not leak. If the valve leaks or is stuck closed, replace it.

3

Remove the pump end cap and using a screwdriver rotate

the rotor, replace cap.

Prior to firing up the boiler to set gas

rates, the Central Heating and Boiler system should be checked for

circulation by running the boiler and pump with gas turned off, to

ensure no air locks occur.

CENTRAL

HEATING

RETURN

COLD

WATER IN

FILLING

LOOP VALVE

CENTRAL

HEATING

FLOW

OPEN

OPEN

CLOSED

OPEN

•

•

•

•

20