Supplied By www.heating spares.co Tel. 0161 620 6677

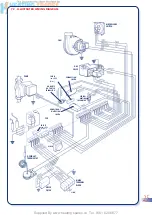

9.15

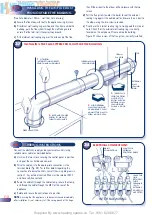

PUMP

9.16

PRESSURE RELIEF VALVE

9.18

AUTO AIR VENT

9.17

PRESSURE GAUGE

9.19

CH EXPANSION VESSEL

SHORT PARTS LIST

10

a)

Remove the casing panels and lower the control box as

described in section 9.1 steps (a) and (b).

b)

Turn the CH flow and return valves to the closed position to

isolate the boiler (see section 5.1), then drain the appliance

using the drain cock provided on the CH flow valve.

c)

Remove the screw securing the electrical connections cover on

the pump, and remove the electrical connections.

d)

Either unscrew the two pump unions and remove the entire

pump (using new sealing gaskets) OR unscrew the four socket

head cap screws and remove the pump head only.

e)

Replace the pump (or pump head), re-assemble in reverse

order, and re-commission the system as explained in section 5.

a)

Remove the casing panels and lower the control box as

described in section 9.1 step (a).

b)

Turn the CH flow and return valves to the closed position to

isolate the boiler (see section 5.1), then drain the appliance

using the drain cock provided on the CH flow valve.

c)

Unscrew the union connections to the pressure relief valve,

and remove the valve.

d)

Replace the valve, re-assemble in reverse order, and

re-commission the system as explained in section 5.

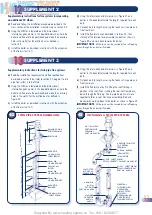

a)

Remove the casing front panels and sealed chamber front

panel as described in section 9.1 step (a).

b)

Remove the combustion chamber front panel and burner

locating bracket (7 screws). Take care not to damage the

insulation.

c)

Turn the CH flow and return valves to the closed position to

isolate the boiler (see section 5.1), then drain the appliance

using the drain cock provided on the CH flow valve.

d)

Remove the plastic pipe from the top of the air vent, and

unscrew the auto air vent using a suitable pipe wrench.

e)

Fit replacement and re-assemble in reverse order.

a)

Remove the casing panels and lower the control box as

described in section 9.1 step (a).

b)

Turn the CH flow and return valves to the closed position to

isolate the boiler (see section 5.1), then drain the appliance

using the drain cock provided on the CH flow valve.

c)

Unscrew the pressure gauge connection from the valve

assembly, unclip the pressure gauge head out of the fascia

panel, and remove the pressure gauge.

d)

Replace the pressure gauge, re-assemble in reverse order,

and re-commission the system as explained in section 5.

In the unlikely event of failure of the expansion vessel diaphragm

it is acceptable to leave the vessel in position and to fit a

replacement vessel (of similar or greater capacity) external to the

appliance but as close as possible to the CH return.

To replace the expansion vessel it is necessary to isolate the

central heating system from the appliance, drain the appliance

and multifunctional boiler chassis then remove the appliance from

the multifunctional boiler chassis and drain the central heating

system. The vessel can then be unscrewed and replaced.

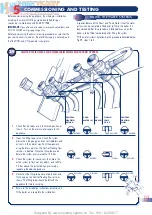

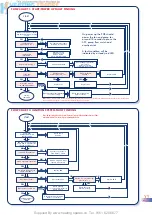

9.20

OPTIONAL TIME CLOCK

a)

Remove the casing panels and lower the control box as

described in section 9.1 step (a).

c)

Remove the six screws securing the plastic PCB housing and

carefully lift it clear of the front panel, to expose the timer

fixing screws.

d)

Unscrew the four timer fixing screws, transfer the wires to the

new timer (referring to the wiring diagrams in section 7 if

necessary), and re-assemble in reverse order.

NOTE:

Should an external time clock be used with the appliance, the internal

clock may be replaced with a switch which is available as an optional extra. If the

clock is to be powered from the appliance connection (terminal 5) then the switch

should be kept ON to maintain a permanent live supply to the clock motor.

Alternatively the intergrated clock can be switched to permanently ON, or the red

jumper on the PCB can be positioned to NO CLOCK POSITION.

f)

Remove the switch body by sliding to the right.

g)

Replace the flow switch and re-assemble in reverse order.

Ensure that the alignment pin is correctly aligned.

Recommission the hot water system as explained in section 5.

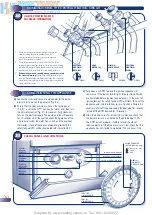

Key G C Part

Description

No

Makers

No.

off Pt

No.

1

BURNER (Natural gas)

1

700535

2

BURNER (Propane gas)

1

700538

3

INJECTOR (Natural gas)

1

700536

4

INJECTOR (Propane gas)

1

700537

5 IGNITION

ELECTRODE

1

500588

6 DETECTION

ELECTRODE

1

500589

7 GAS

CONTROL 1

500591

8 PCB

1

500585

9

AIR PRESSURE SWITCH

1

500592

10 FAN

ASSEMBLY 1

988355

11 OVERHEAT

THERMOSTAT

1

550519

12 THERMISTOR

2

500590

13

MAIN HEAT EXCHANGER

1

450978

14

DHW HEAT EXCHANGER

1

450985

15

PRESSURE RELIEF VALVE

1

450987

16

AUTO AIR VENT

1

450908

17 PRESSURE

GAUGE 1

450961

18 PUMP

1

851213

19 MICROSWITCH

ASSEMBLY

2

500593

20

WATER FLOW REGULATOR

1

21

FLOW SWITCH BODY

1

500594

22 EXPANSION

VESSEL

1

450986

23 HEATING

CLOCK 1

600520

300716 STD

300715 GOLD

31