Supplied By www.heating spares.co Tel. 0161 620 6677

33

SUPPLEMENT 2

12

42

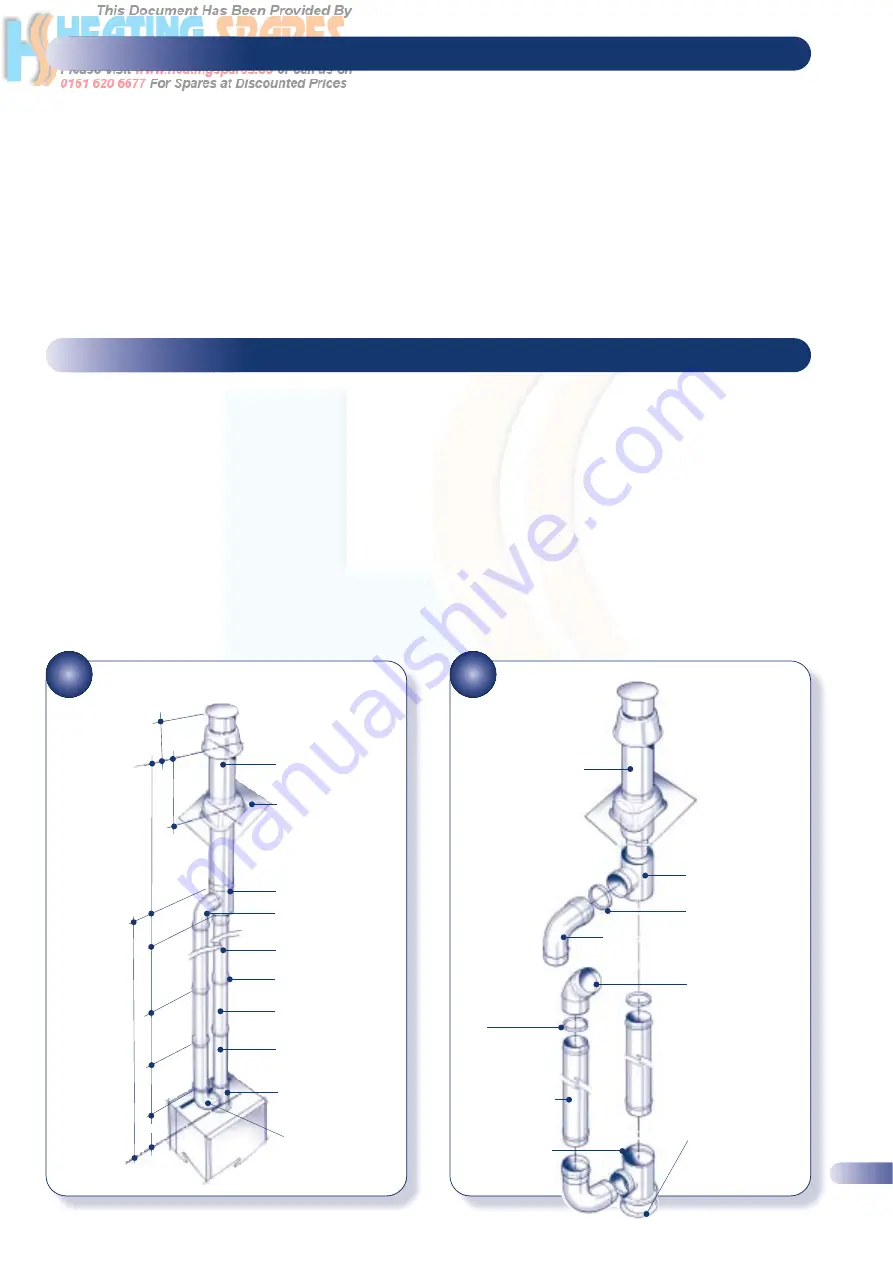

TWIN PIPE SYSTEM DIMENSIONS

43

INSTALLING A TWIN PIPE SYSTEM

SUPPLEMENT 3

13

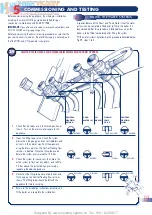

Supplementary instructions for flue systems incorporating

an additional 90° elbow.

a)

Read and follow the installation procedure described in the

main section of the installation instructions up to section 4.2.

b)

Using the MBC as a template and the dimensional

information given earlier in this booklet determine where the

boiler and flue are to be positioned and make the necessary

hole in the wall(s) for the air/flue duct as defined in

section 4.2.

c)

Install the boiler as described in section 4 with the exception

of the flue system (4.7)

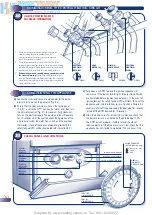

Supplementary instructions for twin pipe flue systems.

a)

Read the installation requirements and flue specifications

described in section 3 but refer to section 2.7 page 6 if a twin

pipe flue system is to be fitted.

b)

Using the MBC as a template and the dimensional

information given earlier in this booklet determine where the

boiler and flue are to be positioned and make the necessary

holes in the wall(s) for the air/flue duct as defined in

Figure 42.

c)

Install the boiler as described in section 4 with the exception

of the flue system (4.7).

d)

Using the information and dimensions in Figure 42 and

earlier in this booklet calculate the lengths required for each

duct.

e)

Cut each duct to length, ensuring that each cut is square and

free from burrs.

f)

Install the flue terminal by first lifting the roof flashing in

position in the roof. Then inserting the terminal from above,

down through the flashing. The two plastic parts will mate

together to form a seal. Continue assembling the ducts

downwards, working back to the boiler as shown in Figure 42

IMPORTANT NOTE:

All flue joints must be secured by two self-tapping

screws through the air duct as illustrated.

d)

Using the information and dimensions in Figure 41 and

earlier in this booklet calculate the lengths required for each

duct.

e)

Cut each duct to length, ensuring that each cut is square and

free from burrs.

f)

Install the flue terminal as described in section 4.7, then

starting at the terminal end assemble the ducts as shown in

Figure 42, and work back towards the boiler.

IMPORTANT NOTE:

All flue joints must be secured by two self-tapping

screws through the air duct as illustrated.

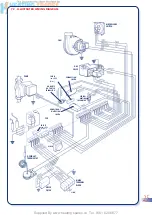

BALANCED FLUE

ROOF TERMINAL

ROOF LINE

T-ADAPTOR

90° 80mm DIA.

SWEPT ELBOW

80mm DIA.

STANDARD DUCT

SEALS AT ALL

JOINTS

80mm DIA.

STANDARD DUCT

80mm DIA.

STANDARD DUCT

T-ADAPTOR

FLANGED

90° 80mm DIA.

SWEPT ELBOW

180mm

430mm

718mm

160mm

1000mm

1000mm

1000mm

160mm

Finest P

ropane Max = 9.0M. If over 7M insulate ducts in roof space.

M/F 45° SWEPT ELBOW

EQUIV. LENGTH 0.8M

PART No. 840510

80/118mm DIA.

VERTICAL FLUE

TERMINAL

PART No. 840506

ADAPTOR TWIN PIPE

TO VERTICAL

TERMINAL

PART No. 840509

SEAL (FITTED)

IN ADAPTOR

M/F 90° SWEPT ELBOW

EQUIV. LENGTH 1.5M PART No. 840507

FIBRE SEAL

SUPPLIED WITH

APPLIANCE &

ALWAYS FITTED

BETWEEN

APPLIANCE AND

T-ADAPTOR OR

FLANGED ELBOW

FLANGED

T–ADAPTOR

PART No.

840511

80mm DIA.

M/F 1m

EXT. DUCT

PART No. 840508

SEAL FITTED

IN DUCT AT

FEMALE END

F

F

F

F

F

F

F

M

M

M

M

M

M

M