14

4.3.4

a)

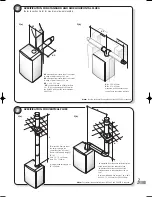

The vertical flue terminal kit (Part No: 988378) contains full

assembly details.

b)

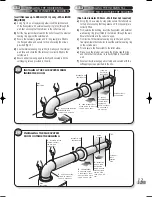

Measure the vertical distance from the top of the appliance to

the roof line (Fig 20), and calculate the extension ducts

required.

c)

Starting at the boiler, fit the vertical flue socket with gasket, the

standard duct and the required extensions. Ensure all ducts

are engaged correctly and secured using the self-tapping

screws provided in the kits.

d)

Fit the vertical flue terminal adaptors.

e)

Working from outside the building, fit the vertical flue terminal

ensuring correct engagement of the inner and outer ducts into

the flue adaptors.

f)

Ensure that the roof flashing and sealing components are

secured to the roof.

PREPARING AND INSTALLING

THE VERTICAL DUCT

FLUE SYSTEM ASSEMBLY

AND DIMENSIONS

20

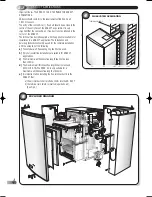

4.4

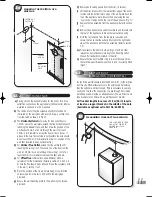

Connect the gas supply to the

1/2

inch BSPF (located at the

bottom, right hand side of the appliance) isolation valve using a

suitable jointing compound. (Fig 21.)

GAS CONNECTION

4.5

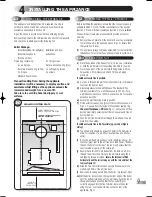

a)

Refer to section 3.8 for detailed information.

b)

The appliance is supplied with two 22mm copper tail ends

suitable for compression or soldered fittings.

Use extreme

care if soldering joints near to the appliance. If

boiler is located in tight space it is recommended to

remove the pipes from the boiler.

c)

The system

FLOW

must be connected to the

UPPER PIPE

.

The system

RETURN

must be connected to the

LOWER PIPE

.

Note: It is recommended to connect Hero 90 to

28mm system pipes.

WATER CONNECTIONS

PIPEWORK

21

•

BALANCED FLUE

ROOF TERMINAL

•

ROOF LINE

•

100/60mm TO

118/80mm DIA

ADAPTOR

•

100/60mm DIA

EXTENSION DUCT

•

100/60mm DIA

EXTENSION DUCT

•

100/60mm DIA

EXTENSION DUCT

•

STANDARD DUCT

•

VERTICAL

SOCKET

•

425mm

•

•

50mm

767mm

767mm

•

•

•

•

•

•

767mm

30mm

1046mm

max

430mm

180mm

MAIN GAS

INLET

FLOW

PIPE

RETURN PIPE

•

•

•

•

Hero 1/03 TO PRINT 8/5/03 10:45 am Page 14