Instruction Manual PSx3xxEIP

7

Versions with higher torques (from 10 Nm):

Here the force connection is made via a feather key DIN 6885-A5x5x12.

The clamping ring is not freely rotatable but consists of two halves, the fixed part of

the hollow shaft and the loose clamping clamp. The keyway is located in the half that

is fixed to the output shaft. When sliding onto the shaft to be driven with the key

inserted, its angular position must be aligned with the keyway in the PSx3xx. After

pushing on, the PSx3xx is fixed with the 2 screws in the flexible clamping ring half.

Make sure that both screws are tightened as equally as possible (tightening torque of

the screws with 3 mm hexagon socket: 1.5 Nm).

The information on torque support applies in the same way as described above.

For PSE30x-14, PSE32x-14, PSS30x-14 and PSS32x-14, the position of the anti-

rotation lock can be set at greater distances by unscrewing the base cover, turning it

180° and then screwing it back on. When screwing on, make sure that the seal is

correctly inserted in the floor.

For torques > 5 Nm we recommend to choose the greater distance.

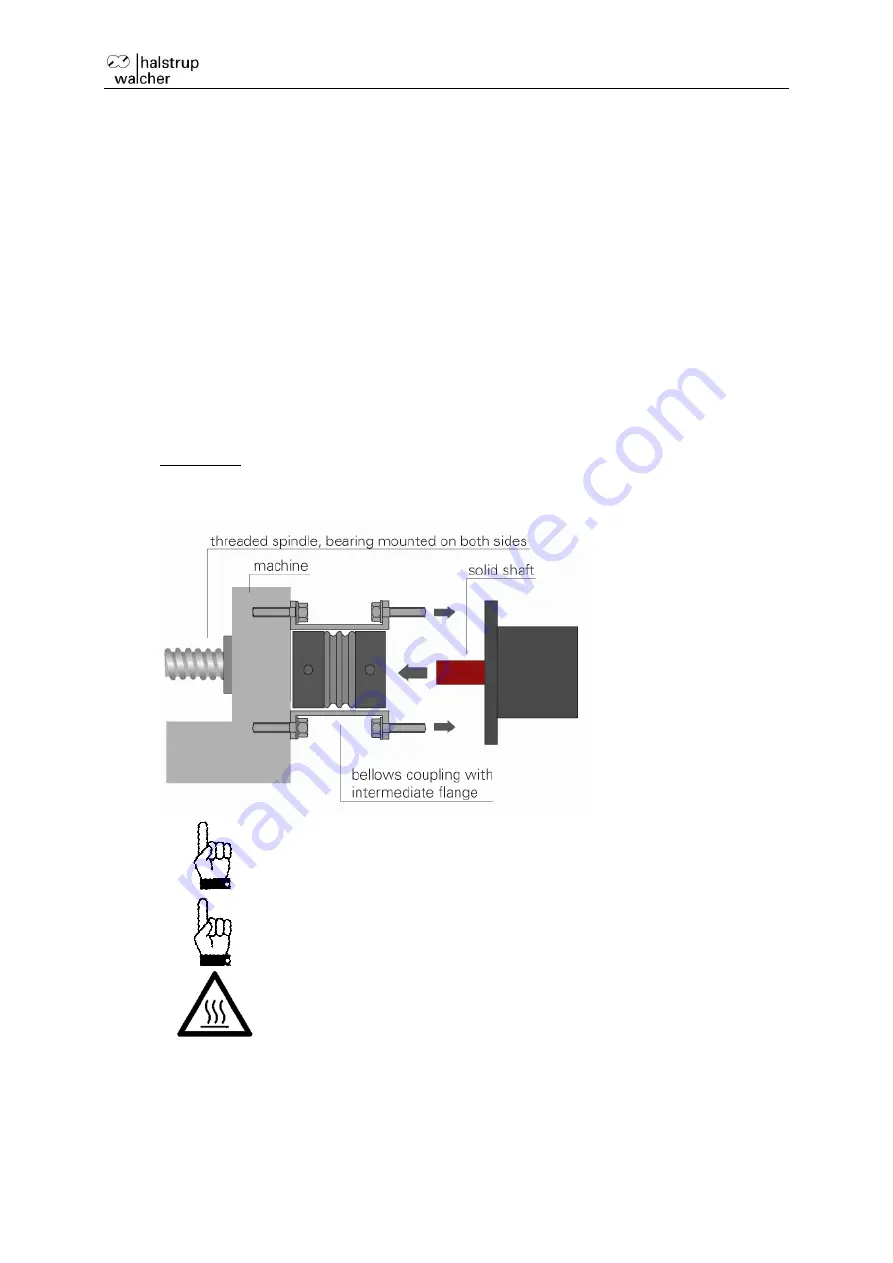

Solid shaft:

The PSx3xx is installed on the machine by mounting the drive to the axis to be driven

using a coupling and an intermediate flange.

Under no circumstances may the housing cover be used for the

purpose of the transmission of force.

Underwater usage of the PSW is not allowed

Please consider that the device might have

a hot surface during operation!