Digital Pulsed Input ( DPI )

Digital Pulsed Inputs are capable of accepting pulsed input information such as for a

road speed sensor. These inputs measure the time periods between the pulses and

can process this information to provide quantities such as road speed.

One

additional input can be connected using the Optional Rear Auxiliary

Harness ( HT040003 )

Digital Pulsed Outputs ( DPO )

Digital Pulsed Outputs are capable of producing pulsed waveforms with varying duty

and frequency. DPO's can be used to control various devices such as thermo-fans,

shift lights, bypass air control valves, boost control solenoids etc.

When a Digital Pulsed output is activated by the ECU the output will switch to ground.

Solenoid valves and shift lights etc can be run directly from the output, however

high current devices such as thermo-fans and additional fuel pumps must be activated

through a relay. This way the DPO is only switching a relay and not a high current

draw device.

Two additional outputs can be connected using the Optional Rear Auxiliary

Harness ( HT040003 )

Digital Pulsed Outputs are limited to 800mA Max current draw.

Digital Switched Outputs ( DSO )

Digital Switched Outputs are capable of switching to ground

DSO's can be used to control relays in an on / off state only.

Two additional outputs can be connected using the Optional Rear Auxiliary

Harness ( HT040003 )

Digital Switched Outputs are limited to 800mA Max current draw.

Analogue Voltage Inputs ( AVI )

Analogue Voltage Inputs accept variable voltage inputs from 0V to 5V. These inputs

can also accept switch inputs that change between two different voltage levels.

The On Voltage and Off Voltage define what the thresholds are between the On and Off

states. The Voltage can be viewed as a channel in the software to determine the

thresholds for a switched input.

Two additional sensors or switched inputs can be connected using the

Optional Rear Auxiliary Harness ( HT040003 )

Wire connections

When using crimp connectors ensure that the correct crimping tool is used – if in

doubt do a pull test on a crimp connector, the wire should break before the wire

pulls out of the crimp. Terminal soldering can weaken a connection and should only

be used as a last resort. If solder joints are used, ensure joints are well isolated

from movement as solder joints are prone to fracture.

When splicing 2 wires it is preferable to use a crimp splice – again if using a solder

joint, ensure joint is limited in its range of possible movement as solder joints are

prone to fracture. Always use heat-shrink sleeving to insulate wires.

6.

Calibration of the Electronic Throttle

Before trying to start the vehicle the Electronic throttle

MUST

be calibrated.

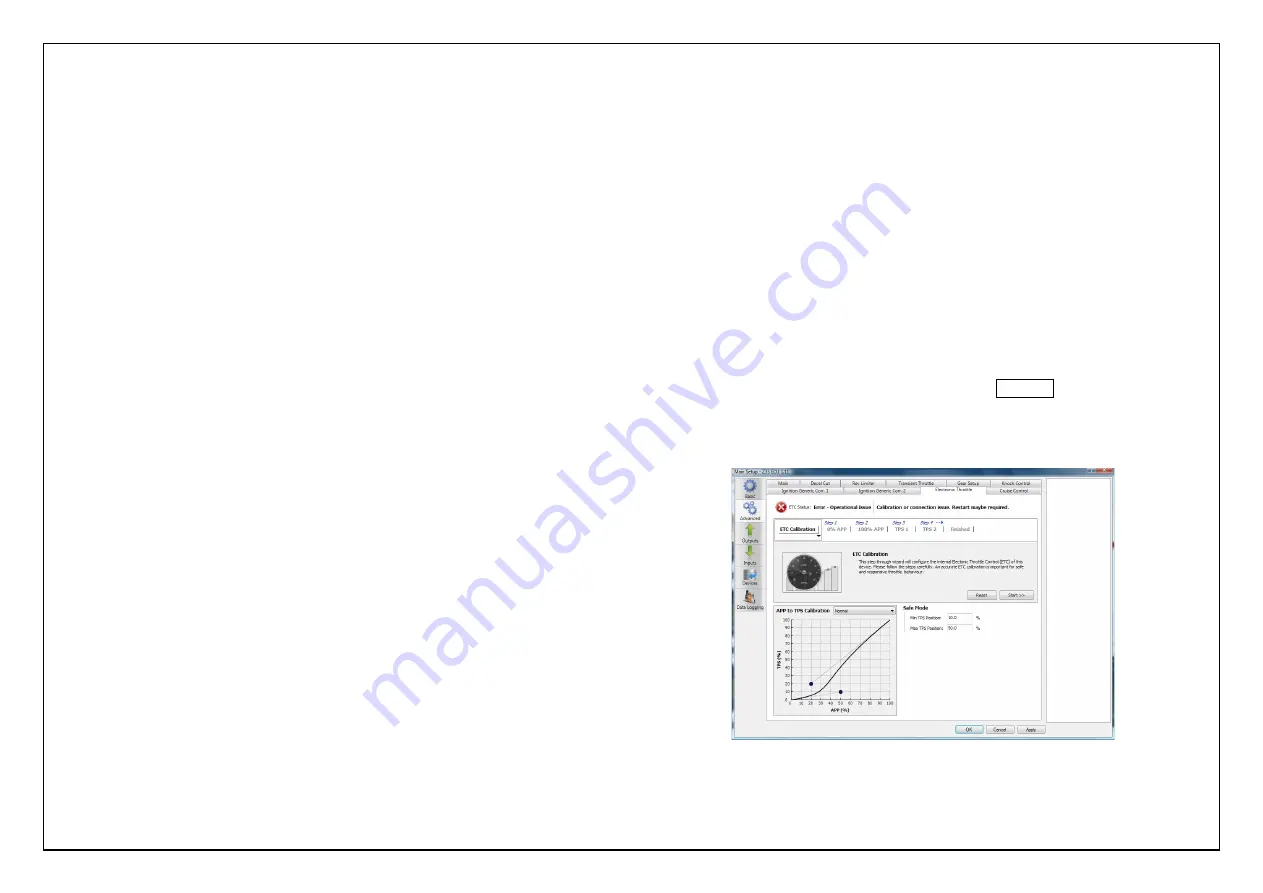

Calibration of the throttle is achieved by using the Haltech ECU Manager ETC

Calibration wizard located in the Advanced Tab within the Main setup page.

The process to Calibrate the Electronic Throttle is outlined below.

•

Install ECU into vehicle as described previously

•

With the ignition switch turned on, connect to the ECU via

Haltech ECU Manager Software using the USB cable provided

•

Navigate to the Main Setup page by pressing F4 or by using the

Setup / Main Setup Tabs

•

Go to the Advanced setup page via selecting the icon on the left of the

main setup page

•

Select Electronic Throttle Tab to display the Haltech Electronic Throttle

Calibration wizard, we are now ready to calibrate the throttle.

To begin the calibration process select the Start >> button

•

The Haltech Calibration wizard will now guide you though the Electronic

Throttle Calibration.

Figure 7- Main Setup Page showing Advanced Menu ETC Calibration Wizard