CJ

OM/20

09/re

v2/EN

3

INSTALLATION INSTRUCTIONS

1.

Inspect the crating carefully. If there are signs of damage, call the freight carrier before uncrating the units.

Carefully uncrate the units. Check all local codes prior to installation, special requirements may be necessary

depending on local building material construction

.

** Important note ** Do not leave unit (s) exposed to extreme temperatures for an extended period

of time, this may cause the protective PVC coating around the unit (s) to become very difficult to

remove.

2.

Position the hood near the actual installation site. In case of multiple hoods, check the engineered set of

drawings for locations. Pay close attention to collar sizes and fire protection layouts, matching the hood

systems to the correct location shown on the drawings provided.

**Check item numbers on crates / hoods vs. drawing item numbers.

3.

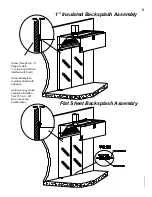

Once the hood is carefully removed from the shipping crate and set in position, the unit is now ready for

installation. If Halton Company has supplied a backsplash assembly, then the splash assembly should

be installed first, for installation procedures.

(See pg. 4)

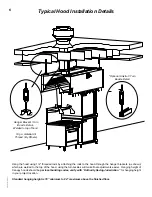

4.

Hang the hood using ½” threaded rods by attaching the rods to the hood through the hanger brackets that are

welded to the top of the hood. Use of turnbuckles will make final adjustment easier. Standard hanging height

for canopy hoods ranges from 78” min. to 84” max. above the finished floor (per local codes having

jurisdiction).

**Noted in installation instructions - (see pg. 6).

**

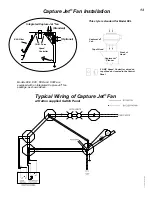

All typical installations for Capture Jet

®

series hoods shown on pages 18-22.

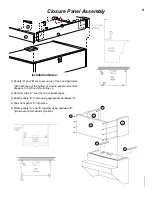

5.

If Closure Panels are supplied by Halton

(see pg. 8)

for details on the installation.

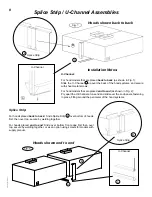

6.

For multiple hoods end to end, or back to back

(see pg. 7)

for Installation of Splice Strips and U-Channels.

7.

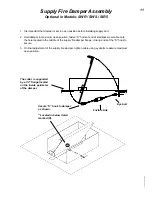

For hoods equipped with a supply fire damper, it is very important to make sure that the fire damper is set in an

open position before connecting the supply duct.

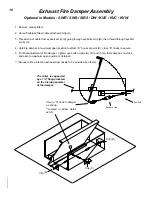

For units with exhaust fire dampers, (see pg. 9), or supply fire dampers, (see pg. 10) for installation

details.

8.

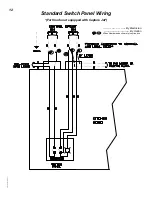

Electrical circuits should be connected according to standard switch panel wiring diagram, shown on

(pg. 11)

.

For Halton Capture Jet

®

series hoods, a typical wiring diagram is shown on

(pg. 12)

.

9.

Grease filters and grease cups must be installed in place before start-up.

10.

Install 100 watt maximum light bulbs in standard incandescent lights or fluorescent bulbs (36” L or 48”L) in

fluorescent lights.

**Note: Halton does not provide bulbs.

11.

Protect the hood from damage under normal job site conditions, until all work is complete and system is ready

to be put into operation.