Page 13

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

Cleaning and Maintenance

The exhaust ductwork has to be periodically inspected and cleaned by the Service Contractor, the exhaust plenum should be also be

thoroughly cleaned at the same time�

When the filters are removed, inspect the inside of the exhaust plenum� Condensed oil vapour should flow to the base and drain to the grease

pots� Particulate and insects, etc� may accumulate inside the hood and cause ponding� Wipe the inside of the exhaust plenum using old rags�

KVF hoods with supply air passing through a perforated front panel should be inspected periodically and wiped clean as required� The front

panel can be removed by removing the comfort nozzles, undoing the screws and lifting the panel out�

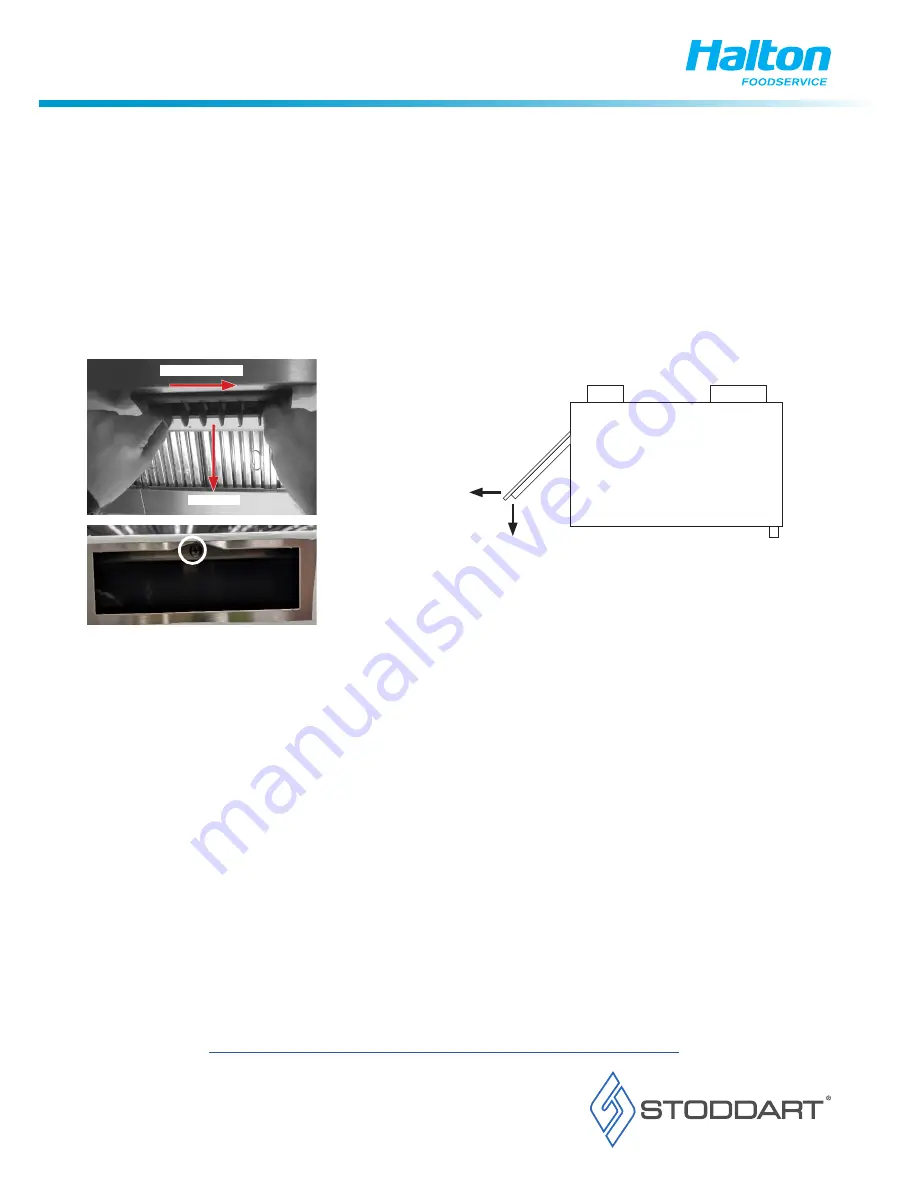

Exhaust Plenum - Inspect and Clean

Supply Plenum – Inspect and Clean

1� Slide to one side

2� Pull out

OUT

DOWN

The recommended inspection periods for extract ductwork, as published in *HVAC TR/19 by Airah – “Guide to good practice� Internal

Cleanliness of ventilation systems”, are as follows:

• Heavy use (12-16 hours/day) – inspect every 3 months

• Moderate use (6-12 hours/day) – inspect every 6 months

• Light use (<6 hours/day) – inspect every 12 months

Ductwork cleaning is usually done by specialist cleaning contractors� TR/19 suggests that the duct is cleaned based on the grease depth in the

duct, according to the following:

• Duct considered clean – grease depth <= 0�05mm

• Duct considered acceptable – grease < 2mm

• Duct should be scheduled for cleaning – grease depth > 2mm

• Duct should be cleaned immediately – grease depth > 3mm

Failure to implement a cleaning maintenance procedure will cause an accumulation of grease and dirt in the ventilation system which will

promote the growth of harmful bacteria, increase the risk of fire, generate odours, reduce airflow through the kitchen and impair the overall

system performance and efficiency� Cleaning frequency may be a condition of insurance policies – check your policy� For the efficient

operation of a kitchen ventilation system, implement cleaning & maintenance procedures� For detailed requirements refer to the HVAC

publication TR/19� Chemical safety procedures should be noted prior to use� If a cleaner containing chlorides, bleaches or hypochlorite’s is

used it must be, afterwards, promptly and thoroughly cleaned off�

* HVAC TR/19 by Airah:

https://www�airah�org�au/Content_Files/Resources/Technical-Bulletin-Kitchen-Exhaust�pdf

Ductwork Surfaces - Inspect and Clean (by Service Contractor)