Page 18

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

Every 6 months (typically) the Capture Jet fan will need to be serviced by a qualified technician� Contact Stoddart at 1300 307 289 for

assistance�

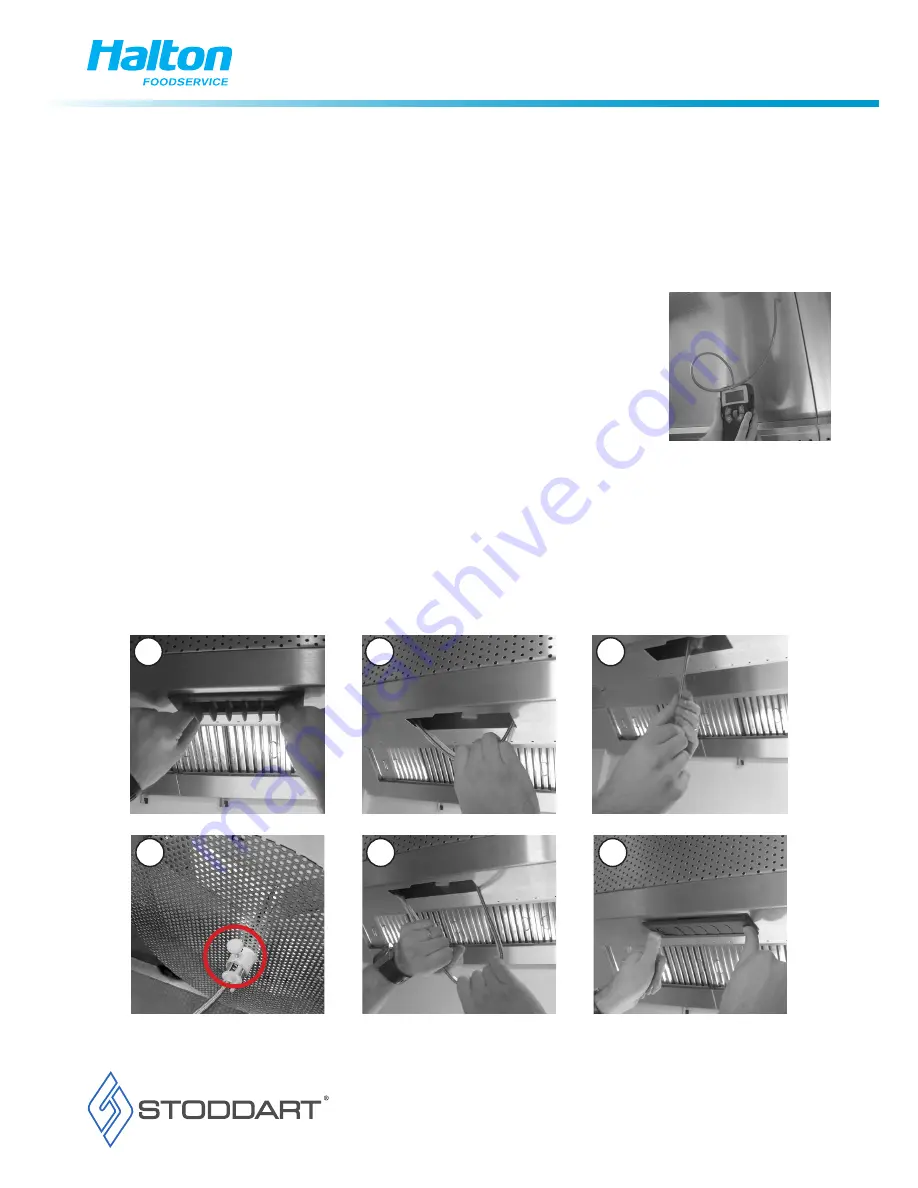

Testing and Balancing Pressure and Airflow - Supply Air Flow

There are two components to the supply air, the T�A�B� pressure point and front face air speed� Note that not every model has a perforated front

panel for supply air and only KVF models require a supply duct to be connected� Other models have an optional supply duct connection�

Before measuring airflows check the exhaust and supply fan on and functioning normally� Airflows must be balanced for each damper in each

hood section� It is important for the hood to have a balanced airflow, to ensure exhaust and supply function efficiently�

Using a manometer measure the pressure at the T�A�B� (Testing and Balancing) point� For hood models with

a perforated front panel, use a vane manometer to measure the face air velocity at 50mm from the front

panel� The air speed must be less than 0�6m/s� Do this for each supply plenum�

Compare results to the rating plate� Values must be within ±10% of specified value and the air velocity

must be less than 0�6m/s� If the values are incorrect, adjust the airflows as per below�

1� To adjust to supply dampers (each supply collar has its own adjustable damper), first remove the comfort nozzles

2� Locate the spring inside the supply plenum

3� Twist the spring to increase (anticlockwise) or decrease (clockwise) the pressure as required

4� The bolt on the axle may need to be loosened before the damper can be adjusted

5� Feed the spring back inside the supply plenum

6� Re-fit the comfort nozzles when done

1

2

3

4

5

6

Cleaning and Maintenance