Page 49 of 92

520008300 08/14

SmartServe™ Drink Mixers Service Manual

Removal and Replacement

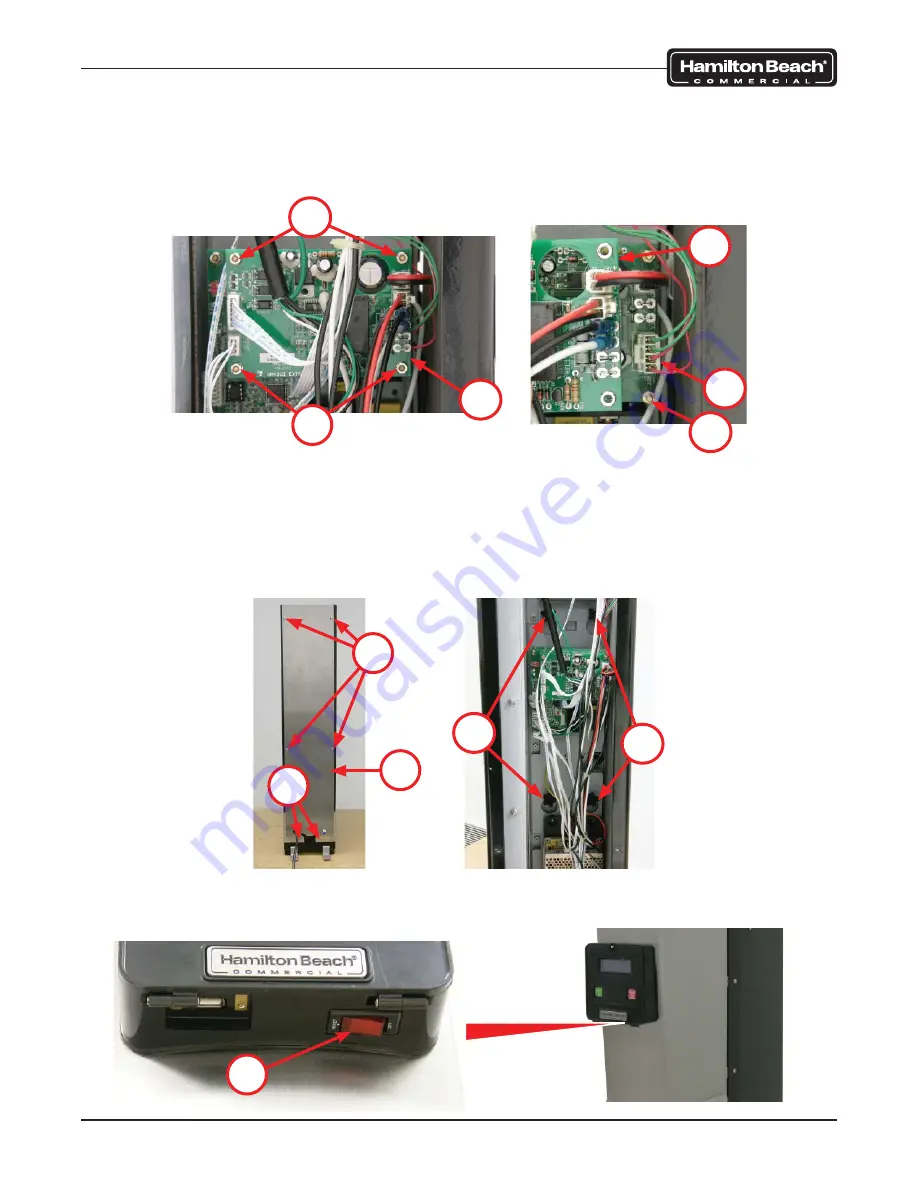

3. Remove four nuts (5) and lockwashers (6) from control board (7).

4. Position the control board (7) to the left to connect the linear motor connector (8).

5. Position the control board (7) on the standoffs (9) and install lockwashers (6) and

nuts (5).

6

5

7

7

8

9

6. Carefully position the power control assembly (10) on the four knobs (4).

NOTE:

Ensure all connections on the power supply and control board are secure. Replace any

wire ties as required.

7. Hand-tighten the four knobs (4).

8. Install the back cover (3) with six screws (2).

2

3

2

4

4

9. Plug in the power cord to the machine, turn the control panel power switch (1) to the

RESET position, and verify machine operates.

1