Hamilton

Home

Products

Canal

Winchester,

OH

76106

61MH0028A

Page

13

SECTION IX: THERMOSTAT WIRING AND

CONNECTIONS

Thermostat Wiring

Thermostat wires connect through side of furnace and should

be no smaller than 24 gauge. Refer to Table 11 for

recommended wire gauge, lengths and maximum current for

each wire gauge.

Maximum

Wire Length

Thermostat

Wire Gauge

Thermostat Wire

Maximum Current

0 - 112 Feet

18

3.0 Amps

0 - 70 Feet

20

3.0 Amps

0 - 30 Feet

22

3.0 Amps

Table 11: Low Voltage Wire Gauge and Max Lengths

NOTE:

There is a 3 Amp slow blow bar fuse located in the

control box that protects the 24 VAC circuit. Replace this fuse

only with the equivalent 3 Amp fuse.

Power wires can enter through the side of the unit or through

the auxiliary entrance, located in the bottom of the unit.

When bringing wiring through the bottom of the furnace,

cable connectors must be installed to hold wiring in place and

to relieve any strain on the wiring.

These connectors will also serve as a seal between the furnace

and the floor. Thus, additional sealing is not required.

The use of a five-conductor cable from the thermostat to the

furnace is recommended for typical heating or heating/cooling

installations with a two or three-conductor cable from the

furnace to the condenser. The thermostat wire colors and the

typical heating/cooling connections are listed in Tables 12 and

13.

A seven-conductor cable from the thermostat to the furnace is

recommended for a typical heat pump installation with a five-

conductor cable from the furnace to the condenser.

The thermostat wire colors and the typical heat pump

heating/cooling connections are listed in Tables 12 and 13.

NOTE:

If the thermostat cable is on the left side of the

furnace move the grommet in the 3/8” hole on the left side of

the furnace casing to the 3/8” hole on the right side of the

furnace casing. Run the thermostat wire cable through the

control box to the low voltage control box. Place the

thermostat wire next to the low voltage terminal block. Attach

the strain relief to the control box. Do not attach the strain

relief to the furnace casing because the sheet metal is too thin.

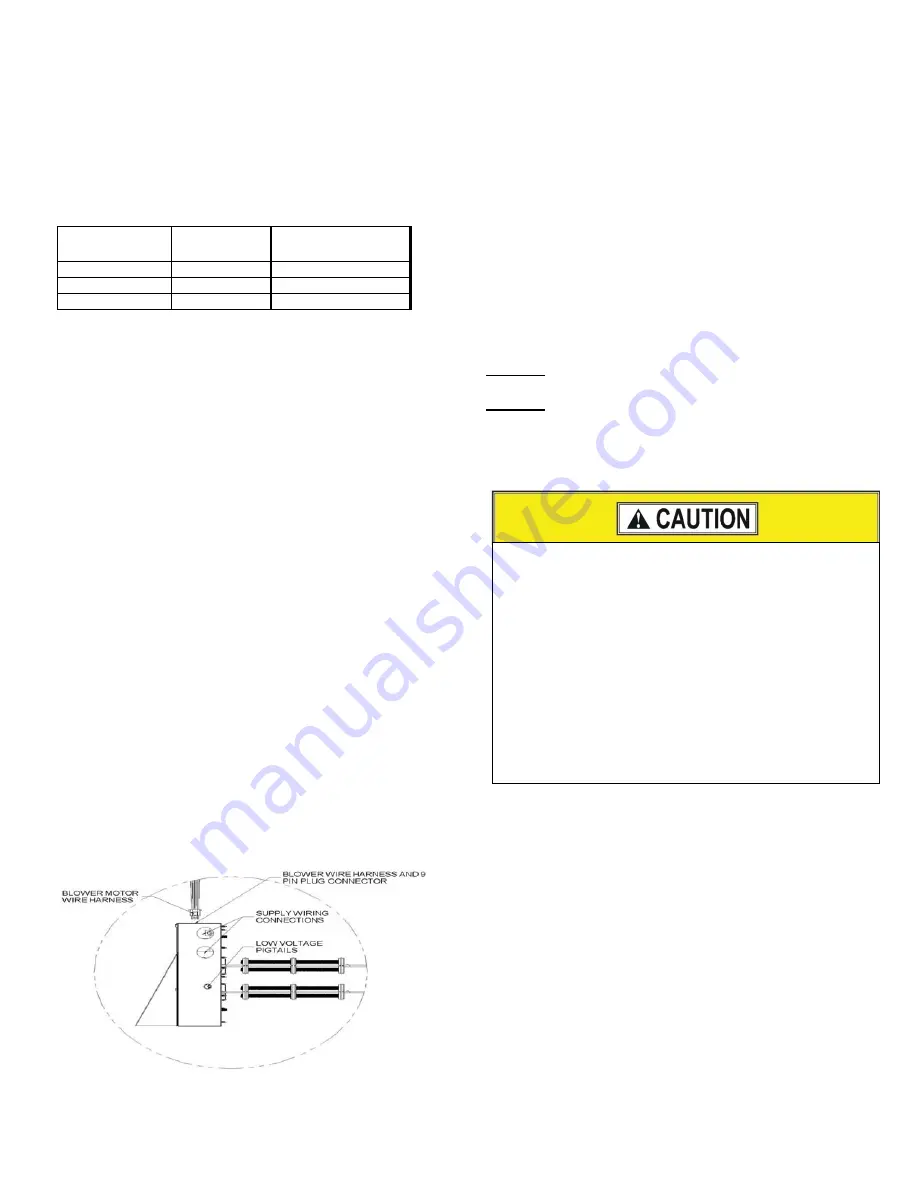

Figure 15: Control Box Power, Low voltage wire

Locations

Thermostat Installation

The thermostat heat anticipator must be-set at 0.7 Amps if the

thermostat has a manual heat anticipator adjustment. This

setting should be checked at the time of installation.

The thermostat may be a “self-setting" type in which case no

heat anticipator setting will be found on the thermostat,

eliminating the need for any field adjustment.

Thermostat should be located on an inside wall in an open area

to more closely regulate average room air, preferably, where

there is air movement back to furnace. Locating height of

thermostat is important. Thermostat should be located

preferably in a hall way upstream from the furnace return

airflow, not within three feet of from any windows and 52 to

66 inches above the floor.

DO NOT

place the thermostat within three feet of any of the

furnace supply air registers

DO NOT

place the thermostat within three feet of any of the

air conditioner supply air registers

Maintenance, operating and/or programming instructions are

in the envelope accompanying the thermostat. Give the

envelope to the home owner.

Separate Heating and Cooling System; Same Thermostat

If the furnace and the cooling unit have separate transformers

be sure to use a thermostat with isolated heating and cooling

contacts “RC” and “RH” to prevent interconnection of Class II

24 Volt Systems Refer to Figures 18 and 19. Cycle furnace

and the air conditioner separately to make sure it will operate

correctly.

Most new thermostats have separate heating and cooling

contacts for use with homes that have a furnace and air

conditioner that are completely separate and each have a 24

VAC transformer for system control. These thermostats have a

“RC” terminal for cooling and a “RH” terminal for heating.

Connect the cooling unit red wire from the “R” terminal on the

outdoor unit to the “RC” terminal on the thermostat and the

RED furnace pigtail wire to the “RH” terminal on the

thermostat. Refer to Figures 18 and 19 for typical low voltage

wire connections.

Do not locate thermostat within three feet of any of the

following items:

1

Furnace supply air registers

2

Cooling unit supply air registers

3

Lights or heat lamps

4

Aquariums

5

Televisions, stereo, amplifiers, surround sound systems

6

Stoves or any cooking appliance

7

Refrigerator

8

Washer and/or dryer

9

Hot water tank

10

Sink or near any hot water

11

Within 15 feet of any electric space heater

12

Within two feet of any sunlight