035-17477-002 Rev. D (1202)

28

Unitary Products Group

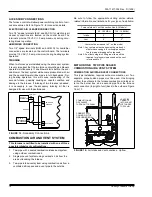

ADJUSTMENT OF MANIFOLD GAS PRESSURE

Manifold gas pressure may be measured by two different pro-

cedures. It may be measured with the burner box cover in

place or it may be measured with the burner box cover

removed. Follow the appropriate section, 2a or 2b in the

instructions below.

1.

Turn gas off at main gas valve. Remove 1/8" NPT plug

from the outlet pressure tap in the main gas valve body

and install a proper manometer tube adapter fitting (refer

to Figure 37). Connect line from gas valve tap to a

manometer.

2.

Read the inlet gas pressure using either of the two meth-

ods below.

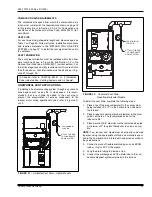

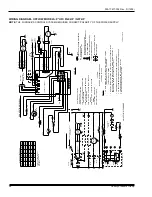

a.

Reading the gas pressure with the burner box

cover in place

- Disconnect the pressure reference

hose from the right side of the burner box. Using a

tee fitting and a short piece of hose, connect the

negative side of the manometer to the burner box

pressure reference port. Connect the positive side

of the manometer to the adapter previously installed

in the gas valve Refer to Figures 38 and 39 on page

29 for connection details.

b.

Reading the gas pressure with the burner box

cover removed

- Remove the screws securing the

burner box front cover plate. Remove the cover. It is

gasketed and may stick in place. Connect the posi-

tive side of the manometer to the adapter previously

installed in the gas valve. There will be no second

connection to the manometer as it will reference

atmospheric pressure.

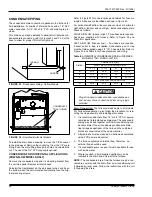

NOTE:

The screw-off cap for the pressure regulator must be

removed entirely to gain access to the adjustment screw.

Loosening or tightening the cap does not adjust the flow of

gas.

3.

Refer to Figure 37 on page 27, for location of pressure

regulator adjustment cap and screw on main gas valve.

4.

Turn gas and electrical supplies ON. Start furnace and

observe manifold pressure on manometer.

5.

Adjust manifold pressure by adjusting gas valve regula-

tor screw for the appropriate gas per the following:

If gas valve regulator is turned in, or clockwise, manifold

pressure is increased. If screw is turned out, or counter-

clockwise, manifold pressure will decrease.

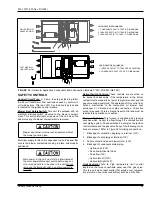

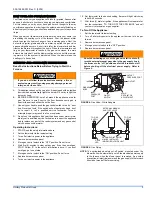

6.

Once the correct gas pressure to the burners has been

established, turn the gas valve to OFF and turn the elec-

trical supply switch to OFF; then remove th pressure tap

at the gas valve and reinstall the plug, using a compound

(on the threads) resistant to teh action of LP gases.

Replace the burner box front cover or the pressure refer-

ence hose.

7.

Turn the electrical and gas supplies back on, and with

the burners in operation, check for gas leakage around

the plug with a soap and water solution.

Nominal Manifold Pressure

Natural Gas

3.5” w.c.

Propane (LP) Gas

10.0” w.c.

The manifold pressure must be checked with the

screw-off cap for the gas valve pressure regulator

in place. If not, the nominal manifold pressure set-

ting will result in an over-fire condition.

If manifold pressure is too high, an over-fire condi-

tion exists which could cause heat exchanger fail-

ure. If the manifold pressure is too low, sooting

and eventual clogging of the heat exchanger could

occur.

Be sure that gas valve regulator cap is replaced

and burner box to gas valve pressure reference

hose is reconnected.