035-17477-002 Rev. D (1202)

34

Unitary Products Group

The blower motor continues to operate for the amount of time

set by the fan-off delay "Jumper" located on the ignition con-

trol board (Figure 16). The heating cycle is complete, and the

furnace is ready for the start of the next heating cycle.

If the flame is not detected within 2 seconds of the gas valve

opening, the gas valve is shut off and a retry operation

begins. If the flame is lost for 2 seconds during the 10 second

stabilization period, the gas valve is shut off and a retry oper-

ation begins. During a retry operation the ventor starts a 15

second inter-purge and the ignitor warm-up time is extended

to 27 seconds. If the flame is established for more than 10

seconds after ignition, during a retry, the control will clear the

ignition attempt (retry) counter. If three retries occur during a

call for heat, the furnace will shut down for one hour. If at the

end of the one hour shut down there is a call for heat, the fur-

nace will initiate a normal start cycle. If the problem has not

been corrected the furnace will again lockout after three

retries.

A momentary loss of gas supply, flame blowout, or a faulty

flame probe circuit will result in a disruption in the flame and

be sensed within 0.8 seconds. The gas valve will de-energize

and the control will begin a recycle operation. A normal igni-

tion sequence will begin after a 15 second inter-purge. If dur-

ing the five recycles the gas supply does not return, or the

fault condition is not corrected the ignition control will lock-out

for 60 minutes.

During burner operation, a momentary loss of power for 50

milliseconds or longer will de-energize the gas valve. When

the power is restored, the gas valve will remain de-energized

and the ignition sequence will immediately restart.

HOT SURFACE IGNITION SYSTEM

MAINTENANCE

AIR FILTERS

The filters must be checked periodically for dirt accumulation.

Dirty filters greatly restrict the flow of air and may cause dam-

age to the system.

Clean the filters at least every three months. On new con-

struction, check the filters every week for the first four weeks.

Inspect the filters every three weeks after that, especially if

the system is running constantly.

All filters used with the furnace are the high-velocity, clean-

able type. Clean these filters by washing in warm water.

Make sure to shake all the water out of the filter and have it

reasonably dry before installing it in the furnace. When

replacing filters, be sure to use the same size and type as

originally supplied.

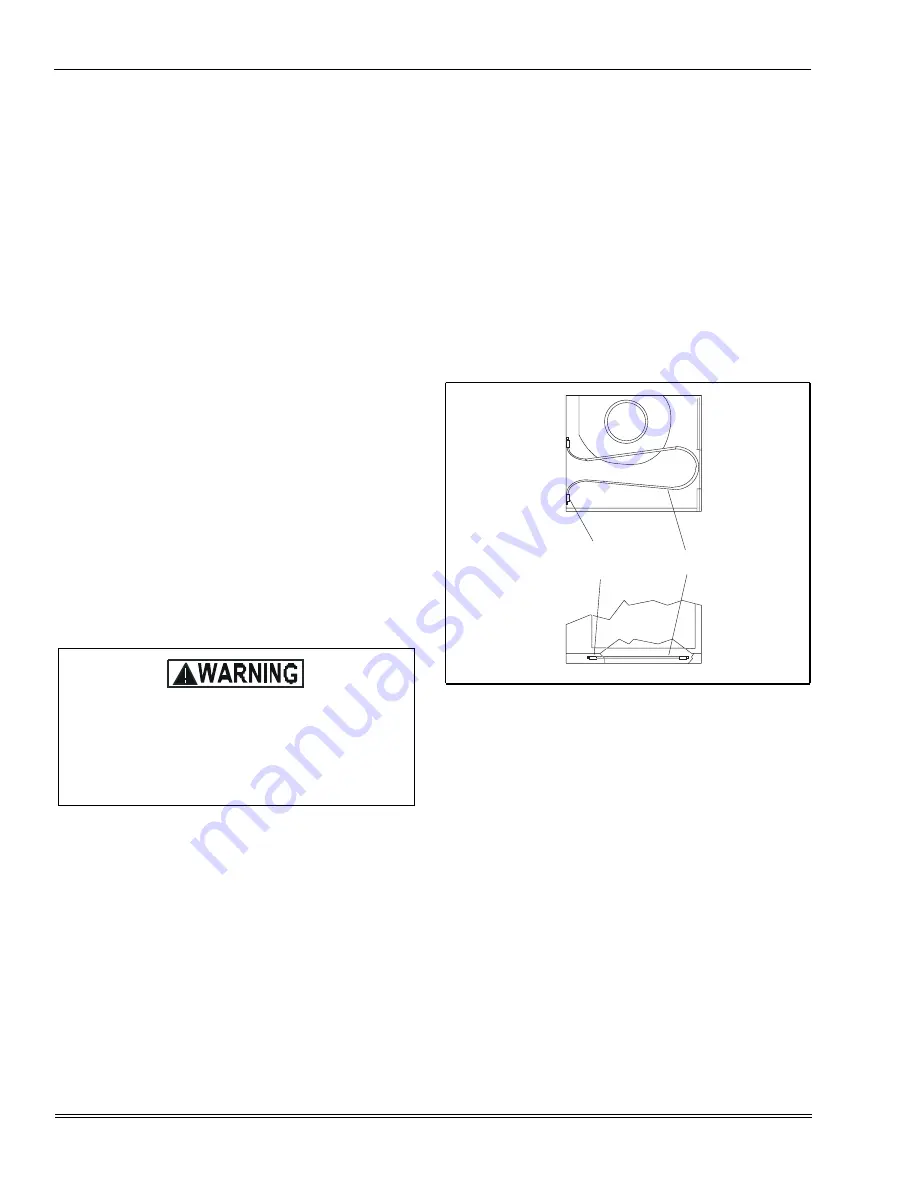

FILTER REMOVAL - UPFLOW MODELS

To remove a filter from the side or bottom location, push the

closed end of the filter retainer to the left until it clears the lip

on the front of the furnace base, which acts as a catch for the

retainer. When the retainer is clear of the flange, it will pivot in

the loops.

Swing the retainer toward the center of the furnace. This will

expose the filter to allow removal. To reinstall the filter, simply

reverse this procedure.

FILTER REMOVAL - DOWNFLOW MODELS

1.

Turn off electrical power supply to the furnace at discon-

nect switch. Remove access doors.

2.

Filters are installed in the plenum area above the blower

assembly. Filters rest against the side of the plenum wall

and are supported in the middle by a frame. Lift filter

slightly to dislodge and remove for service.

3.

Remove the filter and follow the cleaning instructions

above. DO NOT remove the filter stiffener rods, if pro-

vided. When reinstalling the filter(s) be sure it completely

covers the plenum opening.

To reinstall the filters, simply reverse this procedure.

Do not attempt to light this furnace by hand (with a

match or any other means). There may be a

potential shock hazard from the components of the

hot surface ignition system. The furnace can only

be lit automatically by its hot surface ignition

system.

FIGURE 41 :

Upflow Filter Retainer

SIDE

APPLICATION

FRONT

RETAINER

FRONT

BOTTOM

APPLICATION

METAL

LOOPS