18

Hamlet Stoves Wood & Multifuel Stoves

INSTALLATION

Primary flow and return pipes should be 28mm

diameter. The cylinder should be installed at a

higher level than the appliance, and as close to it as

possible (the higher the cylinder the faster the

circulation). The flow and return pipes should not

be longer than 20ft each. Pipe runs should rise

continually from the boiler to the cylinder.

A radiator of approximately 25 sq.ft. should be

connected into the primary circuit, if installed in the

bathroom it provides a means of drying towels in

the summer.

Safety Vent Circuit

This circuit consists of a cold feed pipe, expansion

pipe, and expansion tank. The possibility that water

may boil can never be completely ruled out, and it

is therefore vital to ensure that cold water can be

supplied to the boiler and steam vented from it at all

times.

The expansion tank should have a capacity of at

least 7 % of the system's water capacity. The cold

water feed pipe should be at least 22mm diameter.

There must not be any shut off valves in the circuit.

Pipes should be run to avoid air locks. A spring

safety valve should be fitted to the expansion pipe

close to the boiler.

It is often possible, and is good practice, to utilise

the primary flow and return as part of the safety

circuit. The ball valve should have a copper ball.

The overflow pipe from the expansion tank should

be 28mm diameter copper. Pipes in unheated

spaces must be lagged.

FINAL CHECK

Before handing over the installation to the

customer it is strongly recommended that the

appliance is lit and the functioning of the chimney,

hot water and heating system is checked.

A checklist (Pre-lighting Checks) appears in the

Operating Instructions, but in addition to this the

installer should:

•

Operate the heating system and set the

pump head.

•

Balance the radiators.

•

Re-vent and ensure no air locks.

•

Check the circulation round the primary

system and the heat leak radiator,

particularly when the pump is running, to

ensure circulation is not reversed.

•

Be sure that the chimney is operating and

that ALL smoke and fumes are vented to

the atmosphere through the chimney

terminal.

•

Check all joints and seals.

•

Clean the outside of the appliance to

prevent any stains becoming burnt on.

•

Check the flue draught which should read

1 - 2mm, or 0.1 - 0.2mbar.

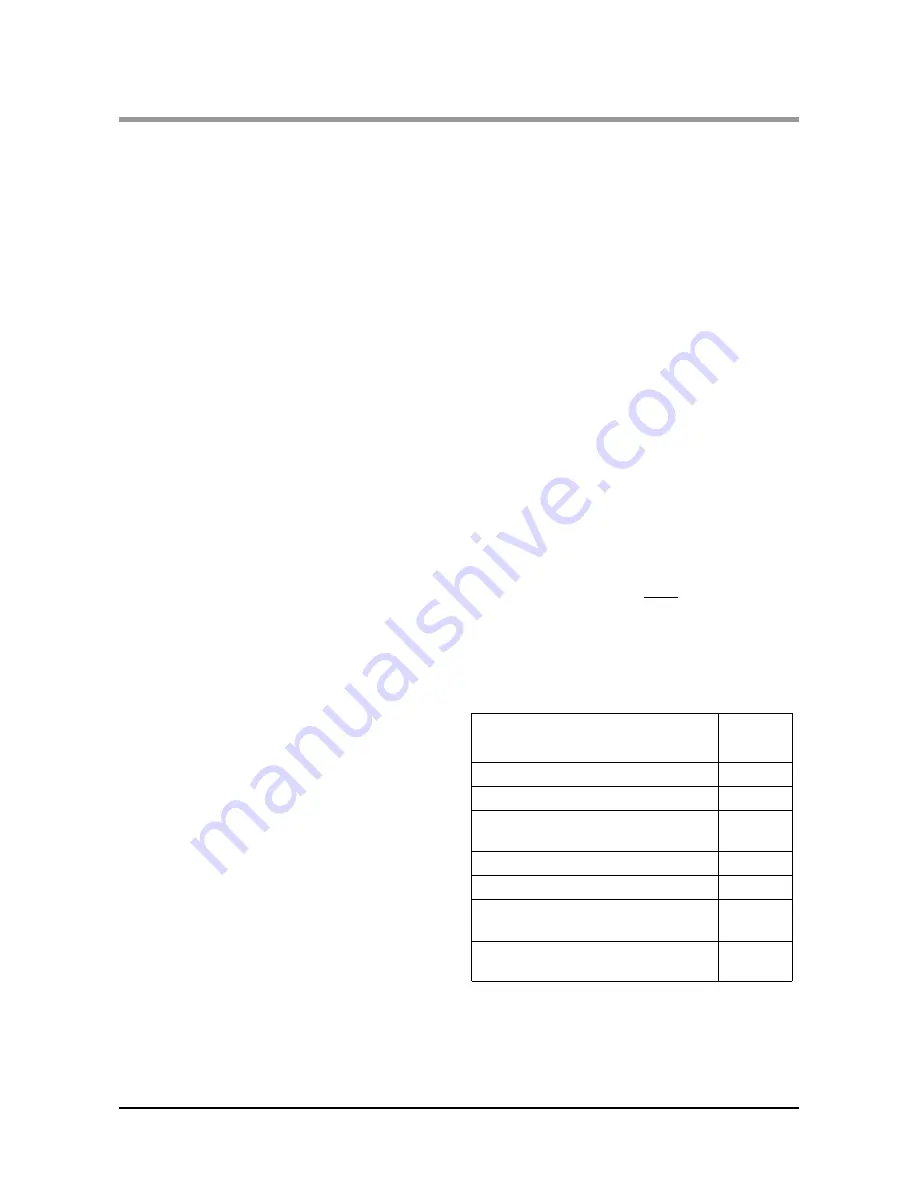

The following details

must

be checked and

completed in full by the installer at the time of

installation. Please answer all questions as fully as

possible.

Hamlet Stoves

can not be held responsi-

ble for chimney or installation.

HOT WATER SYSTEMS

Is the boiler cross-flowed? YES / NO

Are the pipes correctly sized?

YES / NO

What is the calculated output

required to heat the system?

Is a heat leak fitted?

YES / NO

What is the return water temperature?

Is the pump thermostatically

controlled by a pipe stat?

YES / NO

What is the height and distance of the

hot water tank above the stove?