4.6

R

ECOMMENDATIONS FOR USE

•

Most of the drawbacks and failures that may occur during the use of the CRUSHER is caused by the

loosening of the fixing parts and by the presence of leaks that are not promptly eliminated.

•

Since during the running-in phase there is a general settling of all mechanical parts and hydraulic

connections, in this phase it is essential to carry out the checks of the CRUSHER with the utmost

accuracy.

•

Start the work with the CRUSHER only after having positioned the excavator firmly on a flat and non-

yielding surface.

CAUTION: In case of contact with voltage conductors, DO NOT get out of the vehicle, but maneuver

in order to eliminate the contact and reach a safe distance.

4.7

M

ALFUNCTIONS AND TROUBLESHOOTING

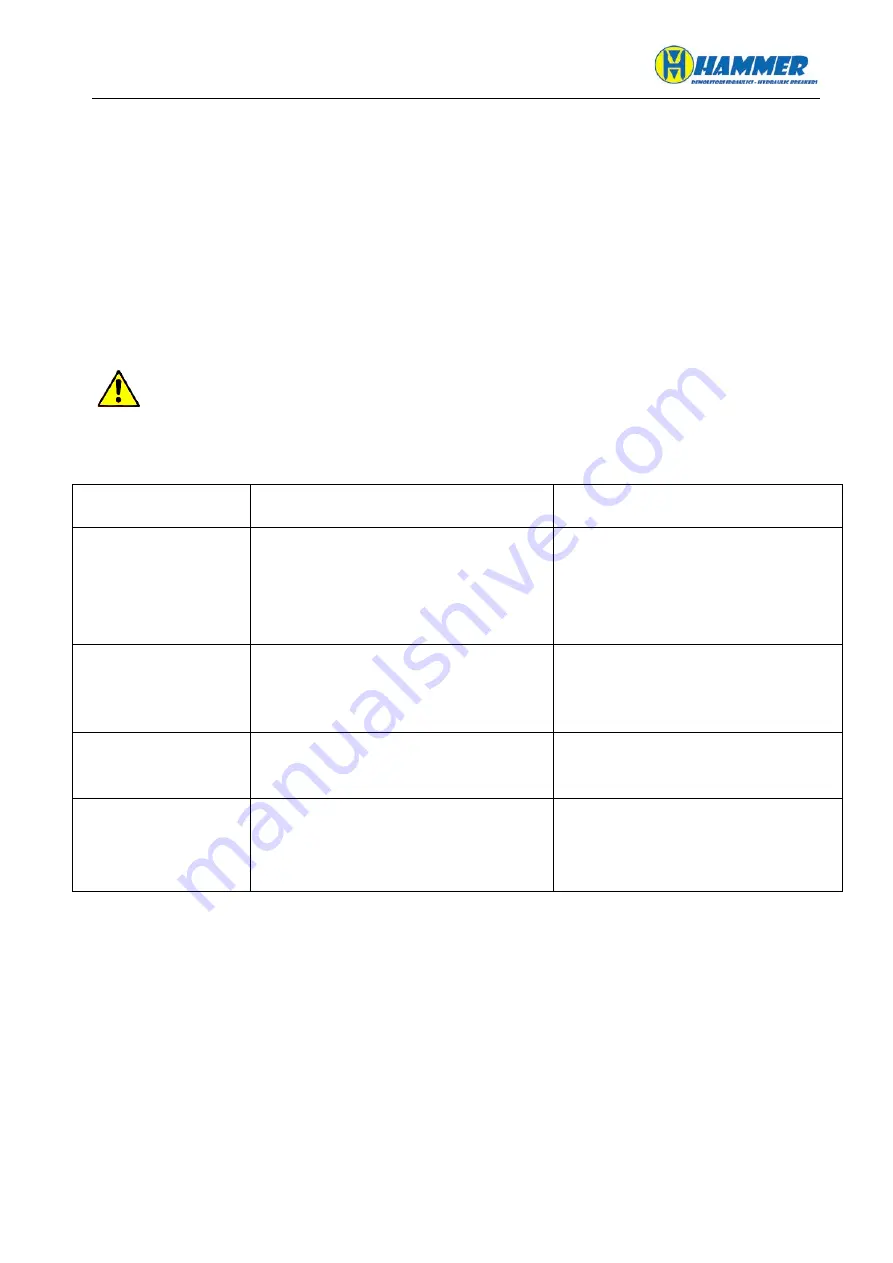

ANOMALY

CAUSES

REMEDIES

Locked rotation

a) Dirt, corrosion

b) Presence of foreign bodies

a) Clean and dislodge the CRUSHER by

lightly hammering it on the front

b) Open the cover of the horizontal plate

and remove the foreign bodies

Jaw blocked

a) Oil pressure too low

b) Dirty or defective non-return valve

a) Check and, if necessary, increase the

control pressure

b) Clean or, if necessary, replace the

valve

Oil leakage from hydraulic

cylinders and/or

connectors

a) Inefficient seals

a) Replace the seals

Insufficient oil pressure

a) Incorrect calibration of the relief valve

b) Jammed relief valve

c) Locked or worn out distributor

d) Worn seals

a) Calibrate the valve correctly

b) Clean or replace the valve

c) Replace the distributor

d) Replace the seals

29

CRUSHER FR SERIES