72

! "

#

$

Panel Saw

K3 basic/K3 winner/K3 e-classic

Required tools:

• 2 Quantity Spanner 10 mm

Faults

11.4 Faults, causes and repairs

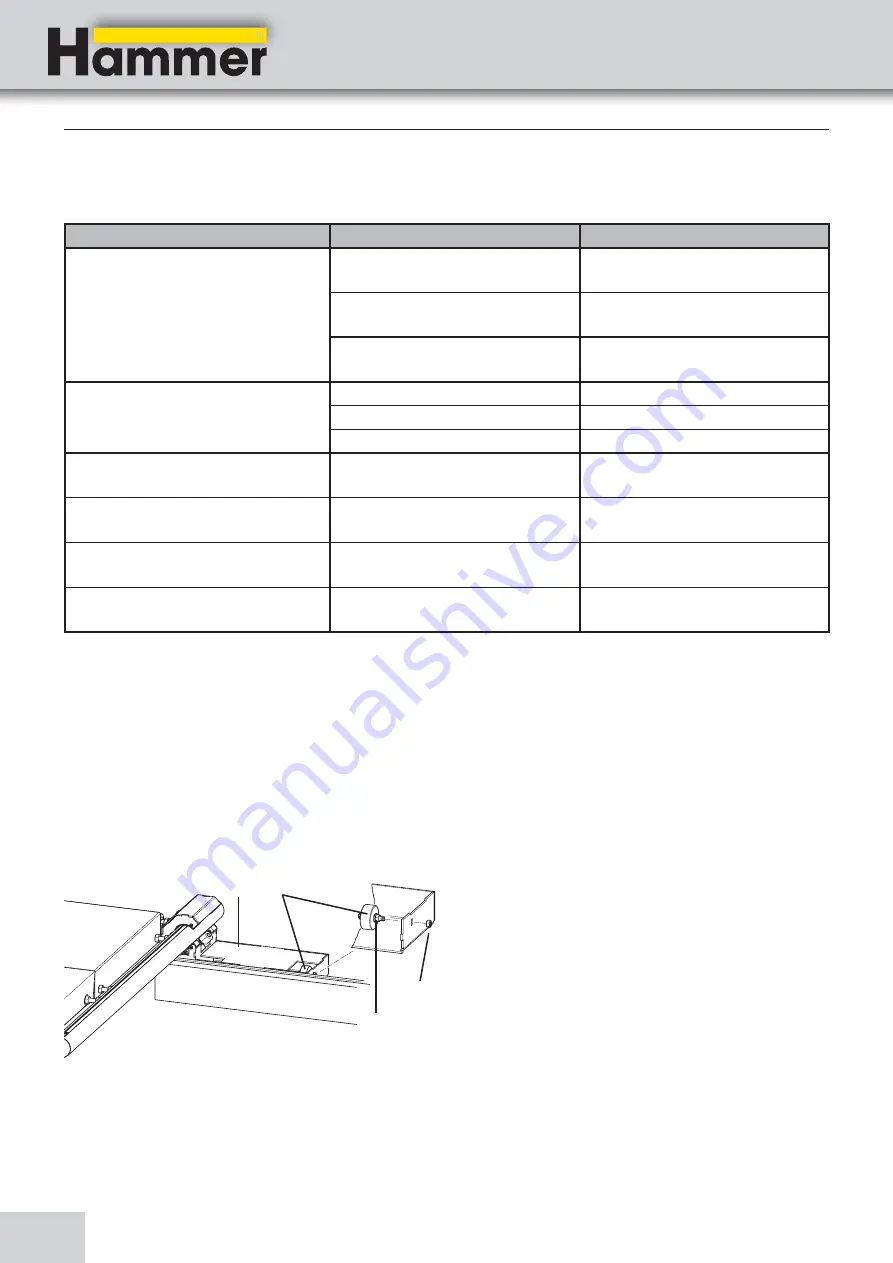

11.5 Adjusting the parallel cutting fence guide height

only possible with: K3 winner

1.

Switch the machine off and ensure that it cannot be

switched on again.

2.

Pivot the parallel cutting fence outwards.

3.

Hold the inner nut tight with a spanner.

4.

Loosen the outer nut with a spanner.

5.

Move the rollers in the mortise.

6.

Tighten the outer nut.

7.

Pivot the parallel cutting fence back.

8.

Check the height adjustment and readjust if required.

!

Parallel cutting fence

"

Rollers

#

Nut (inner)

$

Nut (outer)

Fig. 11-1: Adjusting the parallel cutting fence guide height

Fault

Cause

Repair

Machine does not start

Sliding cover open

Safety break switches activated

Prepare the machine to operate

Error in the electrical contact.

Check the electrical connection

(connecting lead, fuses).

The main switch is off („0“ position). Switch on the main switch („I“

position).

The belts squeal when switched on or

started.

The belt tension is too slack

Retensioning the drive belt

The drive belt is worn out.

Replacing the drive belt

The scoring belt is attrited.

Replacing the scoring belt

The motor is running but the saw blade

is not rotating.

The drive belt is torn.

Replace the drive belt.

The height guide of the parallel cutting

fence is not positioned correctly.

The height adjustment is misadju-

sted.

Readjust the height of the guide

The parallel cutting fence angle is

incorrect.

The angle adjustment is misadjusted. Adjusting/correcting the parallel

cutting fence angle

The full cutting length of the sliding

table is not achieved.

The sliding table ball cage is misa-

ligned.

Realign the sliding table ball cage.