ADJUSTMENTS

AND

TESTING

ANTEA 50 BT – BTS - BTO

Doc.

10059284

Issued

12/2016

Ver.

AC

Page

22 of 25

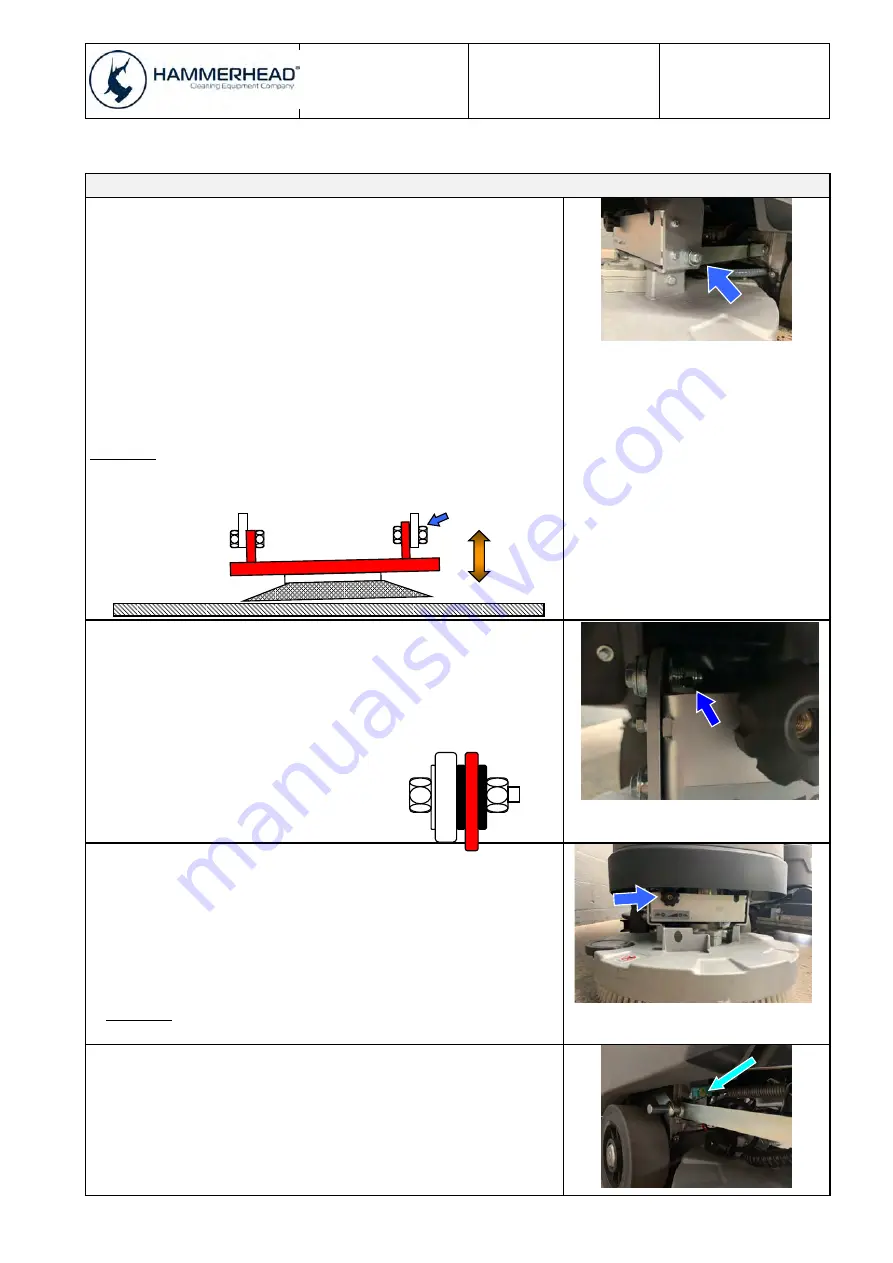

Brush base adjustment (BT version)

1. Base horizontal tilt adjustment.

•

Position the machine on an even and level floor

•

Mount the brush and lower the base to the floor.

•

Loosen the

nut

on the left-hand lifting arm and allow the

base to adapt to the floor.

•

The slotted bracket of the base automatically positioned

correctly.

•

Tighten nut and bolt.

This operation ensures the correct alignment of the base to the

floor for uniform cleaning on the work-track.

Attention: an incorrect angle will cause the machine to pull to

the right or to go into reverse.

2. Base vertical tilt adjustment:

•

Loosen the

self-locking nut

.

•

Adjust the base without the brush so that it

touches at the back first and that the front is 6-7 mm

higher.

•

Tighten the self-locking nut.

Correct adjustment ensures

the correct tilt of the brush

on the floor.

3. Traction adjustment

Adjust the traction b means of the

knob

indicated in the

diagram:

•

Unscrew to increase the traction effect;

•

Screw to decrease the traction effect.

•

Tighten the handwheel after adjustment.

Attention: increasing the traction of the machine diminishes

the width of the floor cleaned.

6. Make sure that when lowering the brush base and activating

levers on the handlebar, the brush starts working. otherwise,

adjust the bar of the

microswitch

.