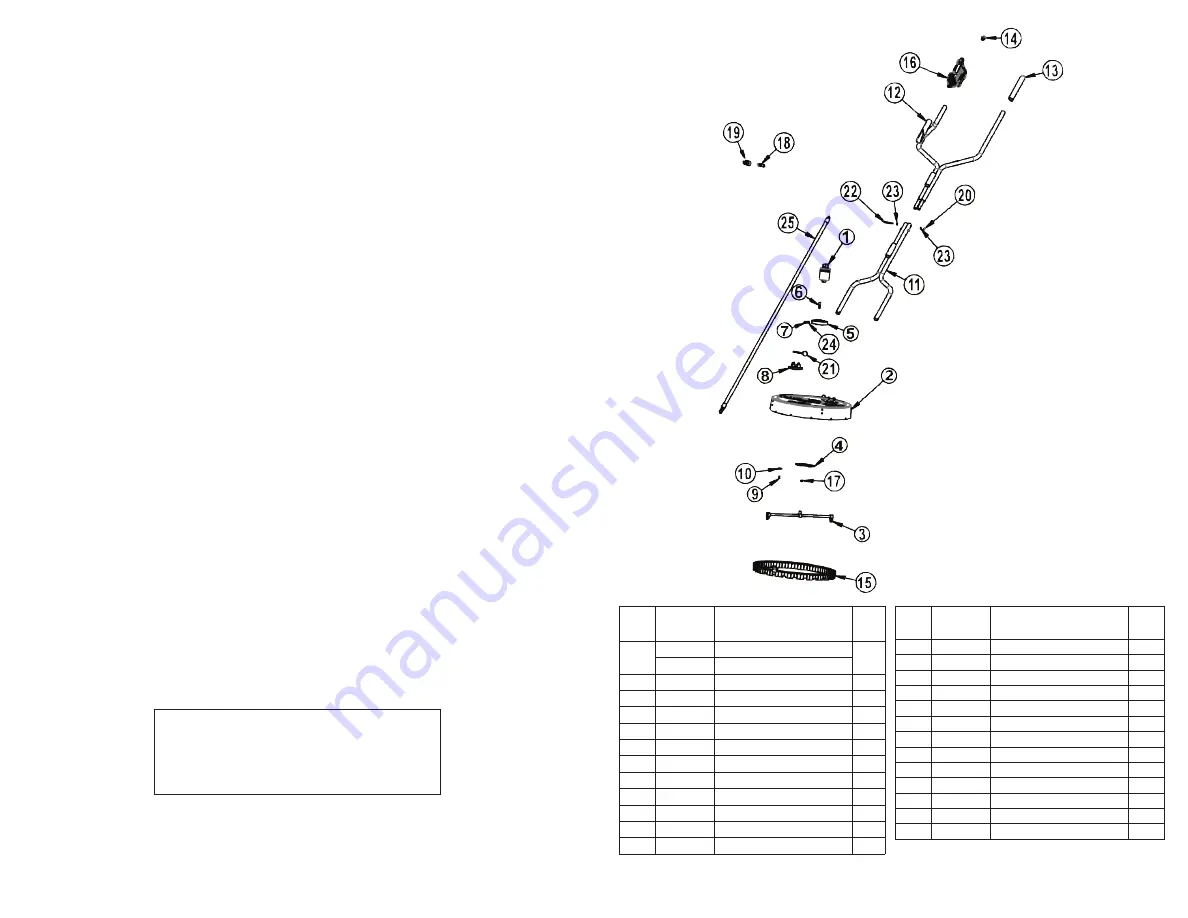

ITEM

NO.

PART

NO.

DESCRIPTION QTY.

1

2103221 Swivel (DFSCP18)

1

2103220 Swivel (DFSCP18GZ)

2

2660119 Deck, GP

1

3

2530052 Arm, Rotary, Assy.

1

4

2630010 Plate, Retaining

1

5

2540023 Collar, Split

1

6

2200055 SHCS, M8

4

7

2200054 SHCS, M8

1

8

2540020 Block, Handle

2

9

2200047 Bolt, M6

8

10

2203406 Washer, M6

8

11

2540021 Handle, Lower

1

12

2540022 Handle, Upper

1

ITEM

NO.

PART

NO.

DESCRIPTION QTY.

13

2660047 Grip, Handle

1

14

2660046 Plug, Handle

1

15

2660049 Brush Assy.

1

16 DG4000FSC Gun, Flat Surface Cleaner

1

17

2200053 Nut, M8 x 1.25

4

18

D10009 Plug

1

19

D10004 Coupler, 3/8 x 3/8-M

1

20

2200026 Nut, M6, Nylok

2

21

2202010 Pin, 55mm, w/Ring, SST

2

22

2200058 HHCS

2

23

2200018 Washer, M6

4

24

2203507

Washer

1

25

2702026

Hose, FSC, 18”

1

General Pump

1174 Northland Drive • Mendota Heights, MN 55120

Phone: 651.686.2199 • Fax: 800.535.1745

www.generalpump.com • sales@gpcompanies.com

Ref 300562 Rev.H

11-12

Operating Pressures: 1,000 to 4,000 PSI

Max Flow: 8.0 GPM

Dimensions: 70” x 18.3” x 18.3”

Weight: 17 lbs.

Operating Instructions

1. Connect to Pressure Washer.

2. Turn water on and open valve. Open trigger gun for flow of water

through nozzles. Nozzles must have flowing spray. If not, remove

tips and clean; reassemble, making sure that groove of nozzle is

parallel to spray bar. Use thread sealant when installing nozzles.

3. Start Pressure Washer. The Hammerhead is ready for operation.

4. Walk slowly behind the Hammerhead cleaning as you go. If

striping occurs, slow down your pace.

5. Periodically check weep hole on bottom of swivel. Water will

seep slowly; if water shoots out, stop and replace seals. Swivel

assembly can be rebuilt.

6. For maximum effectiveness keep spray tips clean. If the machine

vibrates, stop and clean spray tips.

7. DFSCP18GZ ONLY: Use No. 2 general purpose waterproof lithium

grease. For hot water applications, use a quality high temperature

grease. Grease swivel as needed depending on usage. Contact your

dealer with questions about greasing.

DO NOT ALLOW MACHINE TO REMAIN STATIONARY

ON SOFT SURFACES SUCH AS WOOD.

Caution:

Striking any raised obstacle during operation will damage

machine. If contact does occur and results in vibration when

operating machine, STOP and replace spray bar. Continued

operation could result in serious injury or damage to machine.

Ref 300562 Rev.H

11-12