4V LITHIUM-ION SCREWDRIVER 11

OPERATING INSTRUCTIONS

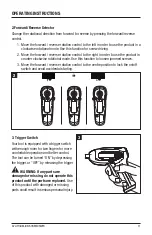

2. Forward/Reverse Selector

Change the rotational direction from forward to reverse by pressing the forward/reverse

control.

1. Move the forward / reverse rotation control to the left in order to use the product in a

clockwise rotational mode. Use this function for screw driving.

2. Move the forward / reverse rotation control to the right in order to use the product in

counter clockwise rotational mode. Use this function to loosen jammed screws.

3. Move the forward / reverse rotation control to the centre position to lock the on/off

switch and avoid accidental starting.

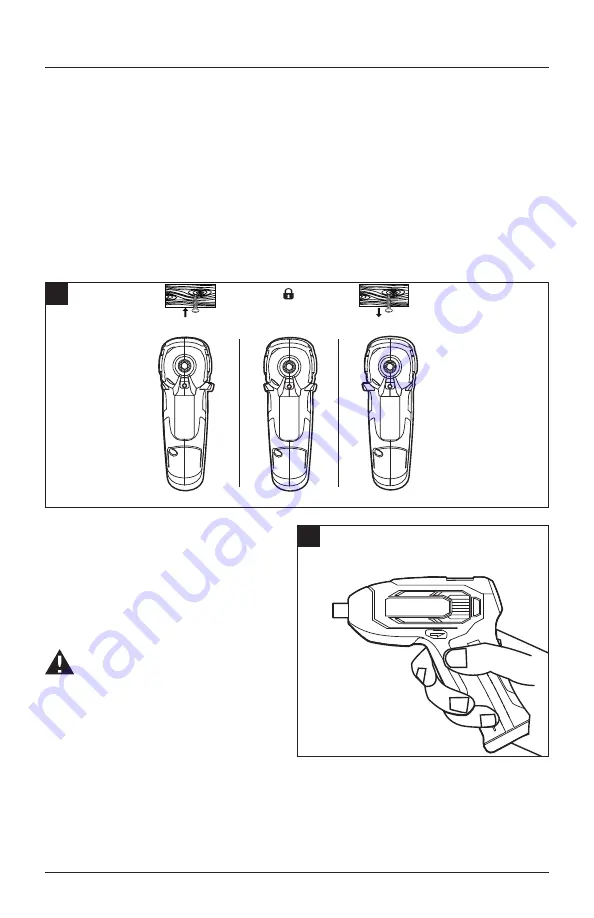

3. Trigger Switch

Your tool is equipped with a trigger switch

with enough room for two fingers for more

comfortable operation and better control.

The tool can be turned “ON” by depressing

the trigger, or “OFF” by releasing the trigger

WARNING:

If any parts are

damaged or missing, do not operate this

product until the parts are replaced.

Use

of this product with damaged or missing

parts could result in serious personal injury.

3

2