6.0 AMP HAMMER DRILL 7

SAFETY INFORMATION

Specific Safety Rules for Hammer Drill

• Hold power tool by insulated gripping surfaces, when performing an operation

where the cutting accessory may contact hidden wiring or its own cord.

Cutting

accessory contacting a “live” wire may make exposed metal parts of the power tool

“live” and could give the operator an electric shock.

• Wear ear protectors when impact drilling.

Exposure to noise can cause hearing loss.

• Use auxiliary handle(s), if supplied with the tool.

Loss of control can cause personal

injury.

• Do not use the power tool with a damaged cord.

Do not touch the damaged

cord and pull the plug from the outlet when the cord is damaged while working.

Damaged cords increase the risk of an electric shock.

• Secure the workpiece.

A workpiece clamped with clamping devices or in a vice is held

more secure than by hand.

• Always wait until the power tool has come to a complete stop before placing it

down.

The tool insert can jam and lead to loss of control over the power tool.

PREPARATION

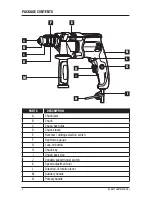

Before attempting to use the hammer drill, familiarize yourself with all of its operating

features and safety requirements.