HG2200/HG2200AT Operator’s

Manual

Each Use

112 - Service

Check Track Tension and

Condition (Tracked Unit)

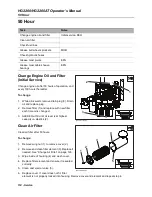

Check track tension and adjust or replace before

startup and every 10 hours of operation.

To adjust:

1. Lift right track using right stabilizer.

2. Remove cover (1).

3. Place straightedge across front track span

from idler to sprocket as shown.

4. Pump EPG into fitting (2) until distance between top edge of bottom of track and straightedge (A) is

1-1/2” to 2” (37.5-50 mm).

5. Lower stabilizer.

6. Drive straight forward one machine length and check tension again.

7. Repeat the process for the left track.

Grease Take Up Drum Bearings

Grease take up drum bearings before startup and

every 10 hours of operation with EPG.

IMPORTANT:

Raise enough to allow the

track to hang freely from the machine.

A

A

11

22

j64om034w.eps

j64om035w.eps

Summary of Contents for HG2200

Page 51: ...HG2200 HG2200AT Operator s Manual Battery Disconnect 50 Controls ...

Page 75: ...HG2200 HG2200AT Operator s Manual Retrieve Tracked Unit 74 Transport ...

Page 87: ...HG2200 HG2200AT Operator s Manual Finish Installation 86 Burst Pipe ...

Page 129: ...HG2200 HG2200AT Operator s Manual As Needed 128 Service ...

Page 133: ...HG2200 HG2200AT Operator s Manual Declaration of Conformity Information 132 Specifications ...

Page 137: ...HG2200 HG2200AT Operator s Manual 136 Service Record Service Performed Date Hours ...

Page 146: ......