HG2200/HG2200AT Operator’s

Manual

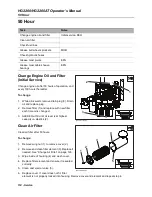

Recommended Lubricants/Service Key

Service - 105

Recommended Lubricants/Service Key

Proper lubrication and maintenance protects HammerHead

®

equipment from damage and failure. Service

intervals listed are minimum requirements. In extreme conditions, service machine more frequently. Use

only recommended lubricants. Use only genuine HammerHead parts and approved lubricants to maintain

warranty.

For more information on engine lubrication and maintenance, see your engine manual.

Item

Description

DEO

Diesel engine oil meeting or exceeding API CF, SAE 10W-30

DEAC

Low silicate, fully formulated diesel engine antifreeze/coolant meeting ASTM D6210

HF

Hydraulic fluid, Grade: Tetra 46 or equivalent meeting or exceeding ISO 45

EPG

Extreme-Pressure Grease - Use lithium based NLGI GC-LB Grade 2, with extreme

pressure additives.

MOB

Open gear lube Mobitack 375 NC

Check level of fluid or lubricant

Filter

Check condition

Adjust, service or test

Change, replace, adjust, service or

test

NOTICE:

Use the “Service Record” to record all required service to your machine.

Summary of Contents for HG2200

Page 51: ...HG2200 HG2200AT Operator s Manual Battery Disconnect 50 Controls ...

Page 75: ...HG2200 HG2200AT Operator s Manual Retrieve Tracked Unit 74 Transport ...

Page 87: ...HG2200 HG2200AT Operator s Manual Finish Installation 86 Burst Pipe ...

Page 129: ...HG2200 HG2200AT Operator s Manual As Needed 128 Service ...

Page 133: ...HG2200 HG2200AT Operator s Manual Declaration of Conformity Information 132 Specifications ...

Page 137: ...HG2200 HG2200AT Operator s Manual 136 Service Record Service Performed Date Hours ...

Page 146: ......