HG2200/HG2200AT Operator’s Manual

Wireless Remote Controller

34 - Controls

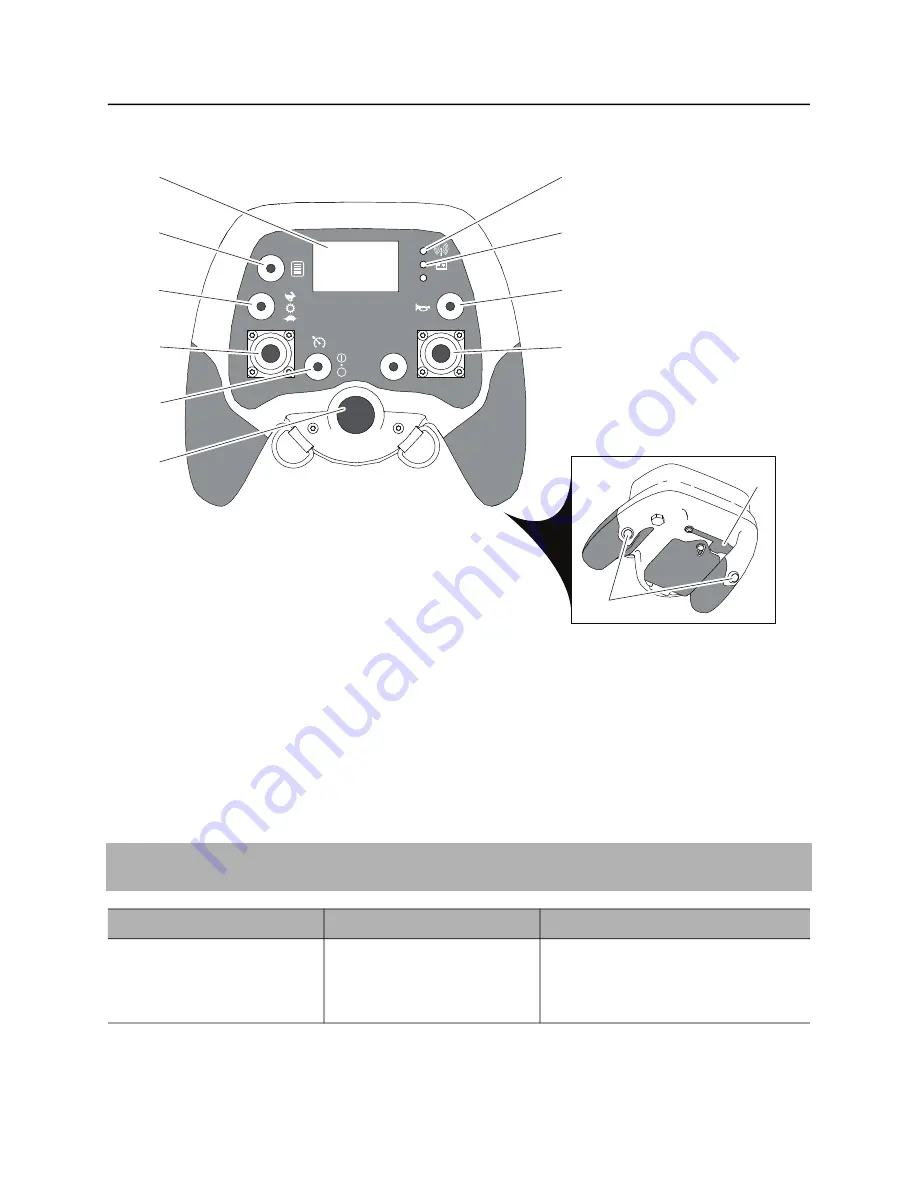

Wireless Remote Controller

1. LCD display

2. Menu select switch

3. Speed selection switch

4. Left multifunction joystick

5. Capstan cruise control

6. Engine stop

7. Communication link indicator

8. Power status indicator

9. Power/Start/Horn switch

10. Right multifunction joystick

11. Operator presence switches

12. Remote hardwire connection

IMPORTANT:

Throttle is automatically set to high when any machine functions are being used. If no

functions are being used, throttle will return to low after 15 seconds.

Item

Description

Notes

1. LCD display

Indicates the selected mode

of operation, battery status,

radio link status, and signal

strength.

j64om010w.eps

1

2

3

4

5

6

7

8

9

10

11

12

Summary of Contents for HG2200

Page 51: ...HG2200 HG2200AT Operator s Manual Battery Disconnect 50 Controls ...

Page 75: ...HG2200 HG2200AT Operator s Manual Retrieve Tracked Unit 74 Transport ...

Page 87: ...HG2200 HG2200AT Operator s Manual Finish Installation 86 Burst Pipe ...

Page 129: ...HG2200 HG2200AT Operator s Manual As Needed 128 Service ...

Page 133: ...HG2200 HG2200AT Operator s Manual Declaration of Conformity Information 132 Specifications ...

Page 137: ...HG2200 HG2200AT Operator s Manual 136 Service Record Service Performed Date Hours ...

Page 146: ......