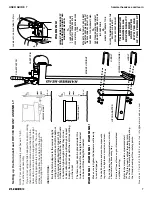

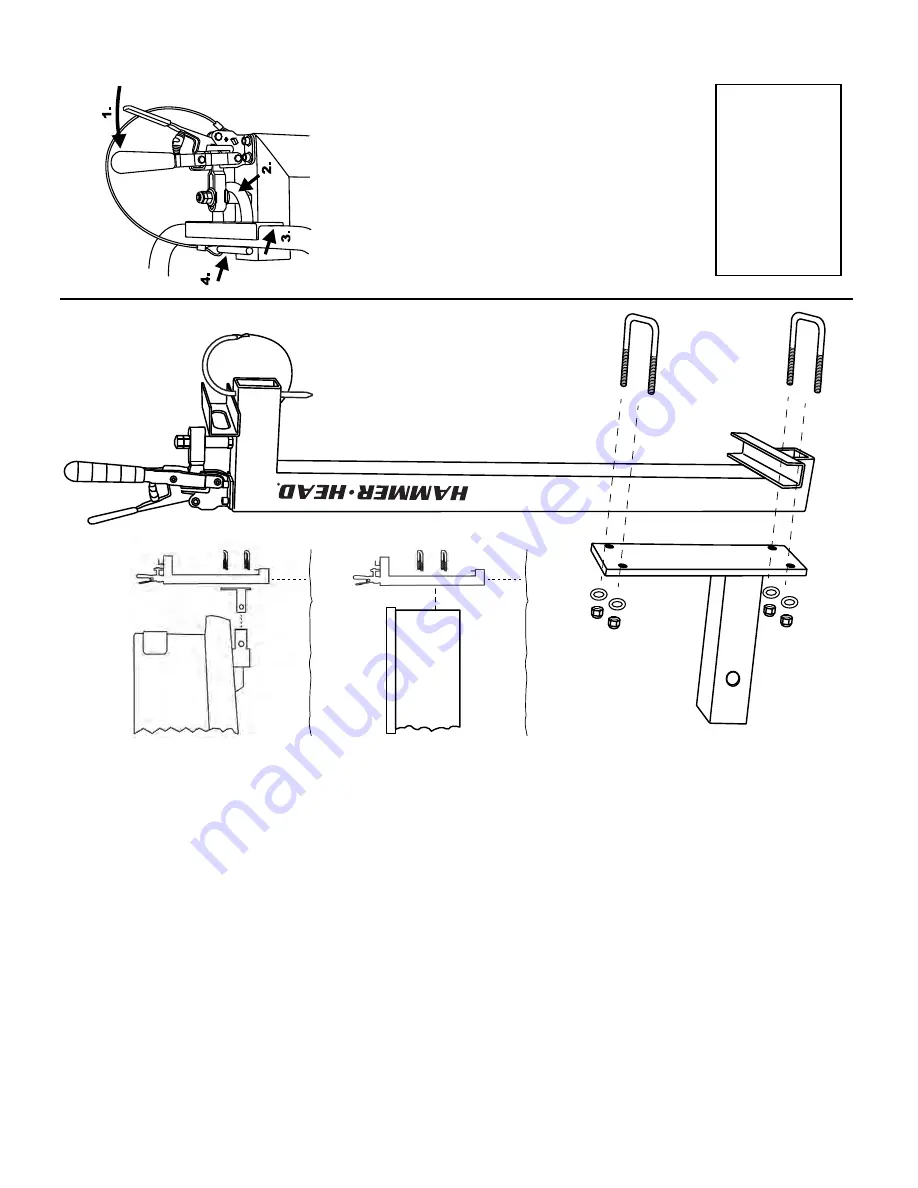

VEHICLE MOUNT

TRAILER MOUNT

12”-16”

12”-16”

Make sure to tighten the hardware sufficiently to avoid slippage.

Check all hardware and mount components regularly for tightness, corrosion, and wear

.

Do not transport your Hammer-Head unit with chemicals in the accessory tray

.

Secure all loose items on your Hammer-Head unit before driving.

Refer to the clamp latch adjustment detail (at right) to properly adjust the clamp latch. Do not use the clamp latch without first adjusting the fit and checking all four safety points.

WARNING!

WARNING!

WARNING!

Se

tti

ng

up

th

e

Hammer-H

ead

HH130

0

M

O

UNT

ASS

EM

BL

Y

NOTE:

Your vehicle (or trailer) must have a 2” hitch

to use the mount assembly

.

If you are not using the hitch adapter for trailer mounting, then U-bolt the Hammer-Head mount directly to the trailer wall in an area that can support the total weight suf

ficiently (approximately 130-140 lbs).

The use of

straps or braces from the vehicle to the top of the mount upright can provide additional support.

CHECK THESE FOUR SAFETY POINTS BEFORE USING THIS

MOUNTING DEVICE:

1.

CLAMP

LA

TCH MUST BE PUSHED

COMPLETEL

Y FOR

W

ARD UNTIL

IT

LOCKS INT

O PLACE

AND SPRING POPS

OPEN

2.

BOTH NUTS ON THE LA

TCH BOL

T MUST

BE TIGHTENED DOWN

AND THE BOL

T

PIN SHOULD MAKE CONT

ACT WITH

CART MOUNT LOOP

WHEN LA

TCHING

3.

CART FRAME MUST MAKE CONT

ACT

WITH MOUNT CHANNEL

WHEN CLAMP

IS LOCKED DOWN

4.

AL

W

AYS USE THE SAFETY

PIN

FAILURE T

O MAINT

AIN OR CHECK THIS

DEVICE COULD LEAD T

O

SERIOUS

ACCIDENT OR INJUR

Y

CLAMP

LA

TCH

ADJUSTMENT DET

AIL

WARNING!

HITCH ADAPTER

U-BOL

T

MOUNT UPRIGHT

LOWER U-CHANNEL

CLAMP

LA

TCH

SAFETY

PIN

U-BOL

T

INSTRUCTIONS:

Bolt the hitch adapter to the mount upright using the included u-bolts so that the bottom of the mount upright will be at least 12-16

inches from the road surface. The cart wheels should be high enough so that they do not

make contact with steep driveways or speed bumps. Do not set up with the cart tires rolling on the road.

The lower u-bolt can be placed under the lower u-channel if more height is needed or above it if less height is needed.

THE OPERA

T

OR

ASSUMES ALL

RESPONSIBILITY

AND RISK

ASSOCIA

TED

WITH THE USE

OF THIS PR

ODUCT

Q

u

e

st

io

n

s?

C

a

ll

5

6

1

-

2

7

8

-8

9

9

2

o

r

e

m

a

il

u

s:

i

n

fo

@

h

a

m

m

e

rh

e

a

d

va

c.

co

m

V1.2 02/01/18

USER GUIDE 7

hammerheadvac.com/learn

V1.2 2/1/18

7