32

Hampton H35 Direct Vent Freestanding Gas Stove

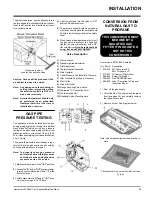

WIRING DIAGRAM - H35-NG & H35-LP

CAUTION: Label all wires prior to

disconnection when servicing con-

trols. Wiring errors can cause im-

proper and dangerous operation.

If any of the original wires as supplied with the

appliance must be replaced, it must be replaced

with CSA type SEW (200

o

C) or its equivalent.

This heater does not require a 120V A.C. supply

for operation. In case of a power failure, the

burner switch and the optional remote control/

thermostat will continue to operate. However,

a 120V A.C. power supply is needed for the

fan/blower operation.

Caution: Ensure that the wires do

not touch any hot surfaces and are

away from sharp edges.

WARNING: Electrical Grounding

Instructions

This appliance is equipped with a

three pronged (grounding) plug for

your protection against shock haz-

ard and should be plugged directly

into a properly grounded three-prong

receptacle. Do not cut or remove the

grounding prong from this plug.

OPTIONAL REMOTE

CONTROL

Use the Hampton Remote Control Kit approved

for this unit. Use of other systems may void your

warranty.

The remote control kit comes with a hand held

transmitter, a receiver and a wall mounting

plate.

INSTALLATION

OPTIONAL WALL

THERMOSTAT

A wall thermostat may be installed if desired.

Connect the wires as per the wiring diagrams.

Note that the wires are connected to the "TH"

on the gas valve. Use table below to determine

the maximum wire length:

Note: Preferable if the thermostat is in-

stalled on an interior wall.

Hampton offers an optional programmable ther-

mostat but any 250-750 millivolt rated non-

anticipator type thermostat that is CSA, ULC or

UL approved may be used.

14 GA.

16 GA.

18 GA.

20 GA.

22 GA.

50 Ft.

32 Ft.

20 Ft.

12 Ft.

9 Ft.

Recommended Maximum Lead Length

(Two-Wire) When Using Wall

Thermostat (CP-2 System)

Wire Size Max. Length

Thermostat Wire Table

CAUTION

Do not connect the millivolt

wall thermostat wires

to the 120V wires.