Hampton HG35-1 Direct Vent Freestanding Gas Stove

19

SYSTEM DATA

For 0 to 4500 feet altitude

Natural Gas

Max. Input Rating 34.7 mj.

Min. Input Rating 18 mj.

Orifi ce Size #33 DMS

Convertible to:

Max. Input Rating 31.6 mj.

Min. Input Rating 15 mj.

Orifi ce Size #37 DMS

LPG

Max. Input Rating 37 mj.

Min. Input Rating 20 mj.

Orifi ce Size #51 DMS

Convertible to:

Max. Input Rating 30.6 mj.

Min. Input Rating 16.8 mj.

Orifi ce Size #52 DMS

ULPG

Max. Input

30.6 mj.

Min. Input

16.8 mj.

Orifi ce Size

#52 DMS

Supply Pressure

Natural Gas

min. 1.13 kPa

LPG & ULPG

min. 2.75 kPa

Manifold Pressure

Natural Gas

0.95 kPa

LPG & ULPG

2.64 kPa

3)

Use appropriate roof fl ashing. Place the

fl ashing under the upper shingles and on top

of the lower shingles approximately half of

the fl ashing should be under the shingles.

4)

Assemble the desired lengths of Black Pipe

and Elbows necessary to reach from the

appliance adapter up through the support

box and fl ashing to proper height as per

Dia. 12, local codes or page 10. Ensure

that all pipe and elbow connections are in

their fully twist lock position.

5)

Ensure

fl ue is vertical and secure fl ashing to

the roof with roofi ng nails. Slide the storm

collar over the pipe section and seal with a

mastic.

6)

Twist lock the fl ue cap on to the last sec-

tion.

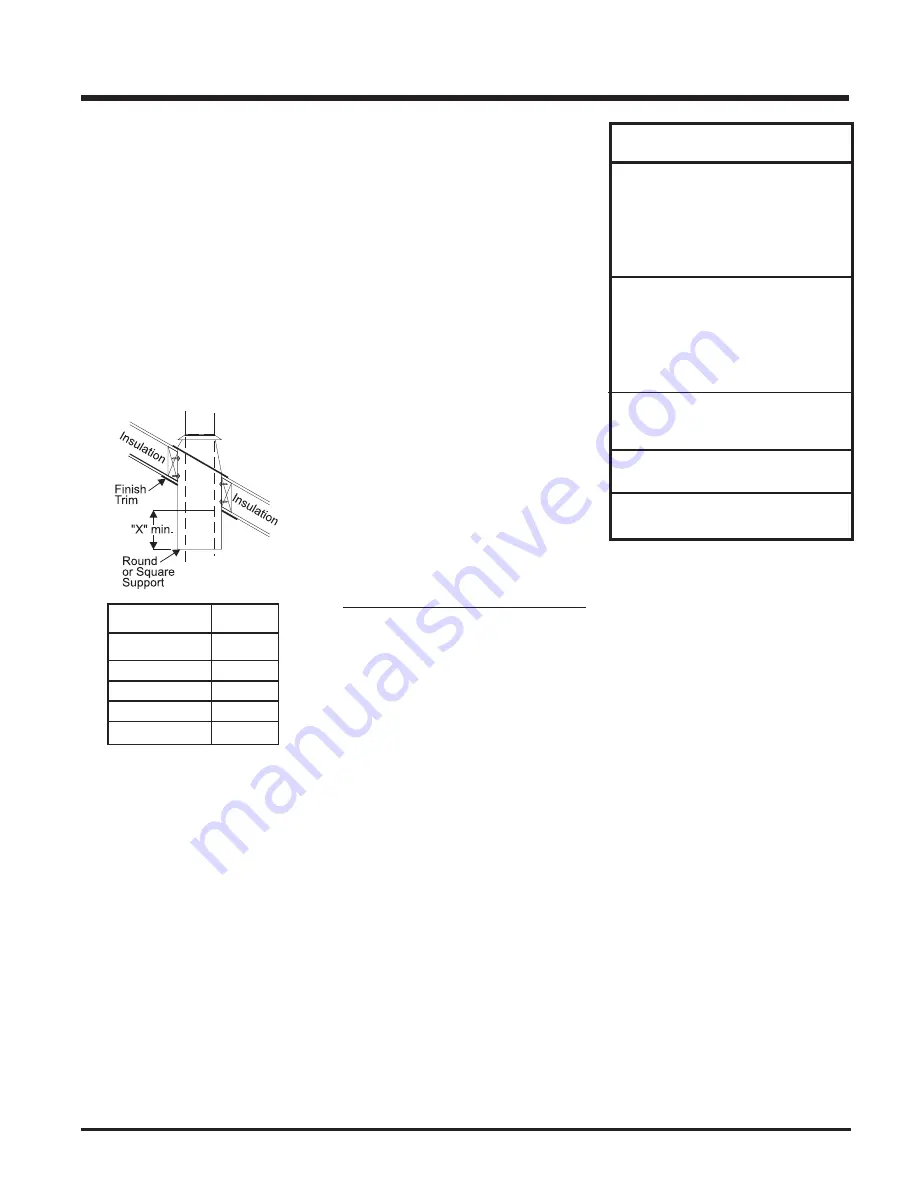

Support Extensions

Round (RDSE) or Square (SQSE)

Steep pitched cathedral ceilings may require

the use of a support extension. This piece fi ts

down inside the support and can be adjusted to

increase the support's length by up to 22". The

extension is attached to the support using the

eight metal screws provided. Be sure there is

at least a 2 inch overlap where the extension

joins the support.

CATHEDRAL CEILING

Round Support (RDS) &

Square Support (SQS)

If your home has a cathedral ceiling (no attic

space between the ceiling and the roof), install

the chimney and support as follows.

1)

Situate the chimney in a convenient loca-

tion as near as possible to the appliance

outlet. Cut and frame a hole in the roof for

the support. The sides of this hole must be

vertical with 1 1/4" clearance.

2)

Place the support in the opening. Lower it

to the correct height as determined by the

table and diagram below.

Using a level, make sure the support is

vertical. If the support extends above the

roof, cut it fl ush with the top of the roof.

Nail the support to the frame opening using

(8) 3" spiral nails or #8 x 1-1/2" screws.

Note: If you are using a 6" square support

you may fi nd it diffi cult to screw it

in place because it is fairly small

inside.

Simpson Dura-Vent has provided angle

brackets with this support which can be

screwed to the outside of the support

box and nailed to surrounding framing as

required. Use a minimum of four #8 x 1/2"

screws per bracket. In some cases these

brackets may need to be trimmed (e.g.:

to fi t under a fl ashing). Place the Finish

Collar around the support and fasten it to

the ceiling using the screws provided.

INSTALLATION

Slope

"X"

0/12 -

2/12

4"

2/12 -

7/12

5-1/2"

7/12 -

12/12

6-3/4"

12/12 - 24/12

7-1/2"

24/12+

12-1/2"

GAS CONNECTION

The gas line should be rigid pipe. Copper may

also be used if approved by AS5601-2004.

The gas connection at the valve is 1/2 male.

For minimum and maximum supply pressure

see the System Data Table.