10 |

HI1150 Hampton Wood Cast Insert

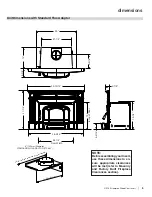

installation

Installation Into a Factory-

built Fireplace

1. When installed in a factory built fireplace, a

full stainless steel rigid or flexible flue liner is

mandatory, for both safety and performance

purposes. When a flue or liner is in use, the

insert is able to breathe better by allowing a

greater draft to be created. The greater draft

can decrease problems such as, difficult start-

ups, smoking out the door, and dirty glass.

2. In order to position the flue liner, the existing

rain cap must be removed from your chimney

system. In most cases the flue damper should

also be removed to allow passage of the liner.

3. In most cases opening the existing spark

screens fully should give enough room for the

insert installation. If it does not, remove and

store.

When referencing installation or connec-

tion to masonry fireplaces or chimneys,

the masonry construction must or shall be

code complying.

Installation Into a

Masonry Fireplace

The insert must be installed as per the requirements

of your local inspection authority.

In Canada this fireplace insert must be in-

stalled with a continuous chimney liner of 5.5"

(140mm) or 6" (152mm) diameter extending

from the fireplace insert to the top of the

chimney. The chimney liner must conform to

the Class 3 requirements of CAN/ULC-S635 or

CAN/ULC-S640, Standard for Lining Systems

for New Masonry Chimneys.

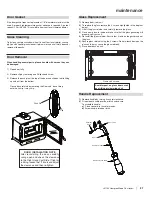

4. If the floor of your fireplace is below the level

of the fireplace opening, adjust the insert's

levelling bolts to accommodate the difference.

When additional shimming is required, use

non-combustible masonry or steel shims.

5. Measure approximately the alignment of the

flue liner with the position of the smoke outlet

hole on the insert to check for possible offset.

If an offset is required, use the appropriate

offset adaptor in your installation.

6. Once the above items have been checked, slide

your insert into position after first positioning

and securing the flue liner to the offset adaptor.

Attach the rod to the adaptor and slide the adap-

tor onto the unit as the unit is slid into position.

Ensure a positive connection.

Secure the adaptor to the unit by using 2 bolts,

flat washers, lock washers and one screw in the

front.

Re-install raincap at completion of installation.

Draft is the force which moves air from the appliance

up through the chimney. The amount of draft in your

chimney depends on the length of the chimney, local

geography, nearby obstructions and other factors.

Too much draft may cause excessive temperatures

in the appliance and may cause damage. An uncon-

trollable burn or excessive temperature indicates

excessive draft. Inadequate draft may cause back

puffing into the room and plugging of the chimney.

Inadequate draft will cause the appliance to leak

smoke into the room through appliance and chim-

ney connector joints. Ensure the heater is installed

in areas that are not too close to neighbors or in

valleys that would cause unhealthy air quality or

nuisance conditions.

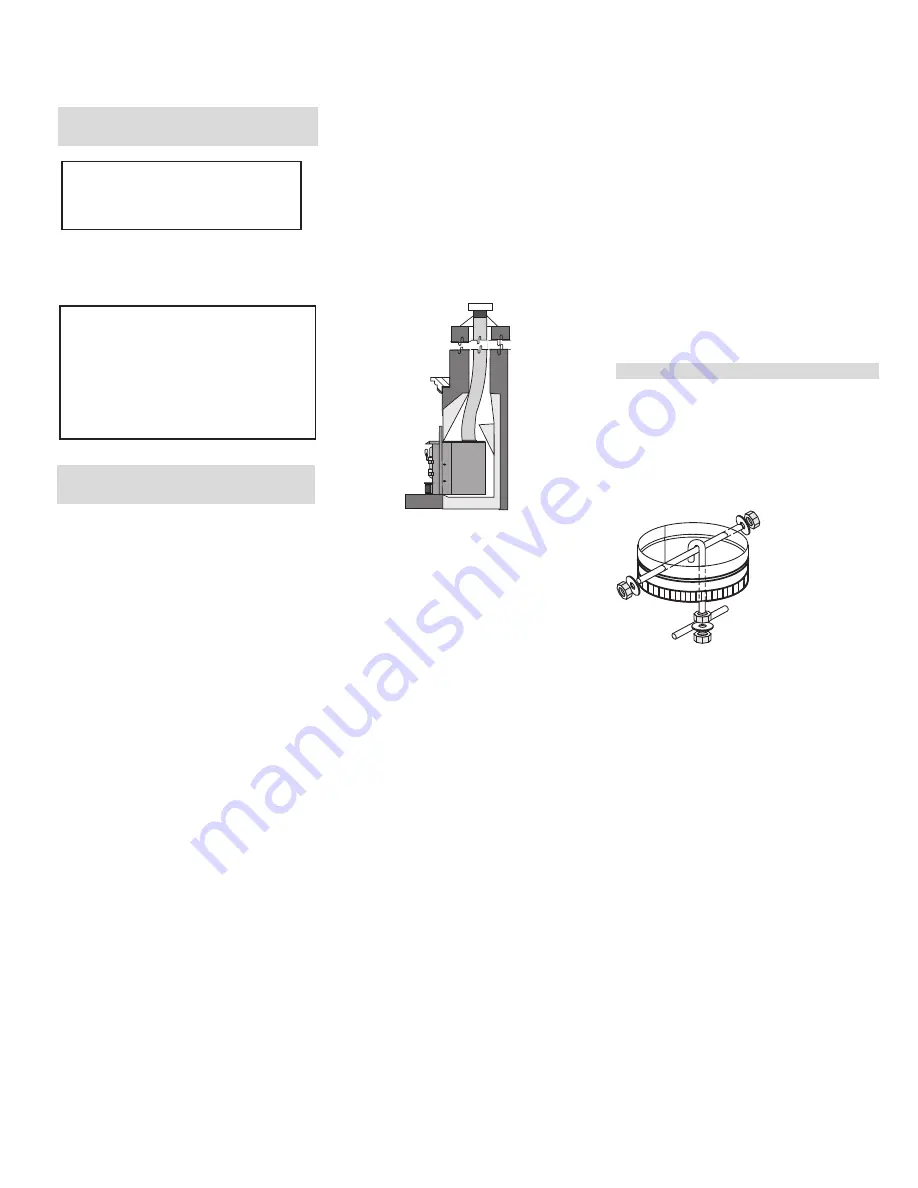

Optional Flue Connector Kit

The Straight Flue Adaptor (Part #846-504) shown

here, may be used to produce a secure connection

between your flue connector and the insert collar.

Detailed installation instructions are included with

the kit.

The following may also be purchased separately

if required to complete the install:

846-506 6" Flue Adaptor-30 degree

846-508 6" Flue Adaptor-45 degree

948-412/P 6" Flue Offset Adaptor (offsets back 4")

846-527 Flue Connector Kit