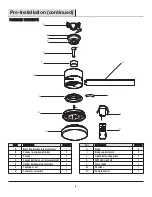

Pre-Installation (continued)

DUAL MOUNTING INSTRUCTIONS

DUAL MOUNTING INSTRUCTIONS

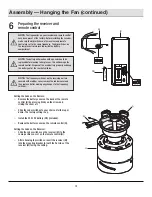

This ceiling fan is supplied with two types of hanging assemblies: the

standard ceiling installation using the downrod with ball and socket

mounting, and the "close-to-ceiling" mounting. The "close-to-ceiling"

mounting is recommended in rooms with less than 8 ft. ceilings or in

areas where additional space is desired from the floor to the fan blades.

When using the standard downrod installation, the distance from the

ceiling to the bottom of the fan blades will be approximately 12 in. The

"close-to-ceiling" installation reduces the distance from the ceiling to the

bottom of the fan blades to approximately 9 in.

Once you have decided which ceiling installation you will use, refer to the

corresponding sections and procedures during the assembly period.

Where necessary, each section of the instructions will note the different

procedures to follow for the two types of installation.

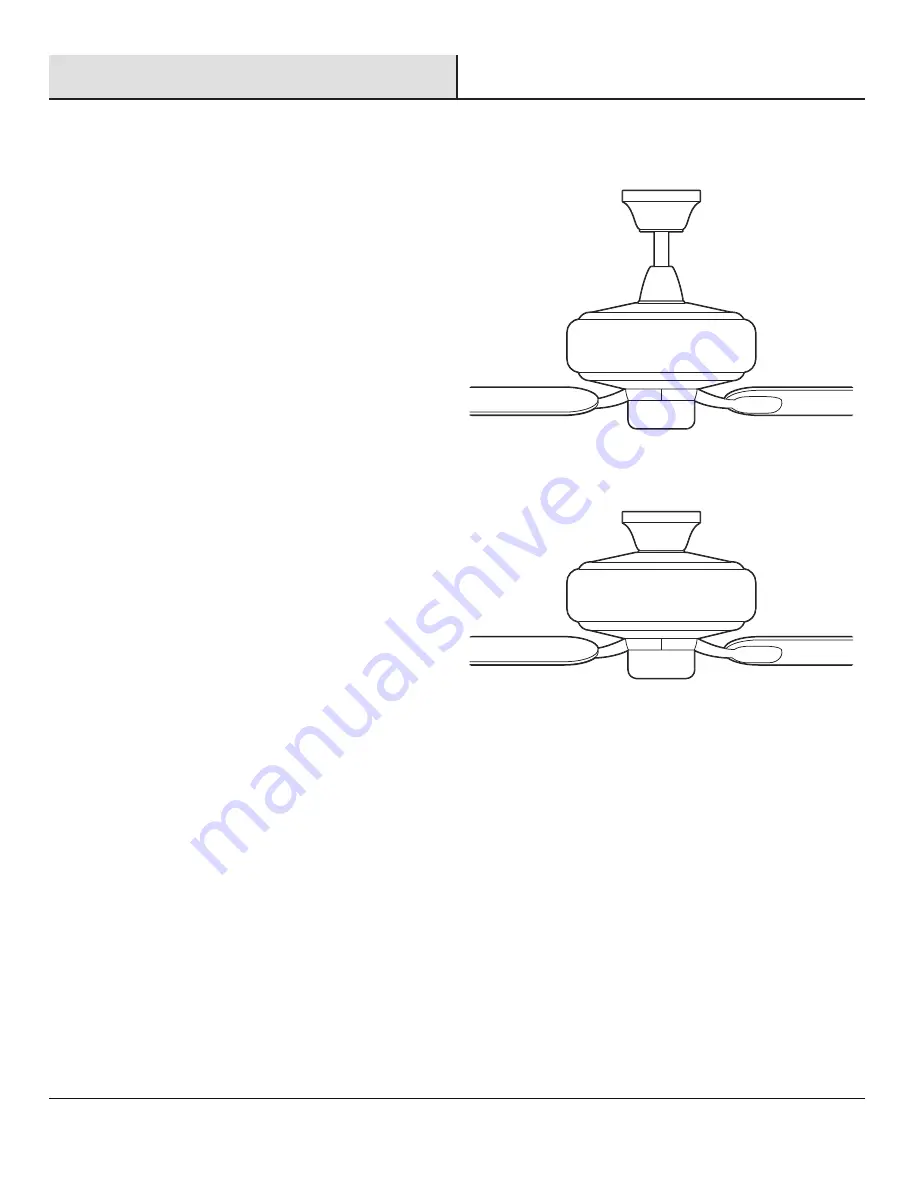

Standard Ceiling Mounting

Close-to-Ceiling Mounting

7

HAMPTONBAY.COM

Please contact 1-855-HD-HAMPTON for further assistance.