©1995 Hamtronics, Inc.; Hilton NY; USA. All rights reserved. Hamtronics is a registered trademark. Revised: 1/31/00

- Page 1 -

CONSTRUCTION.

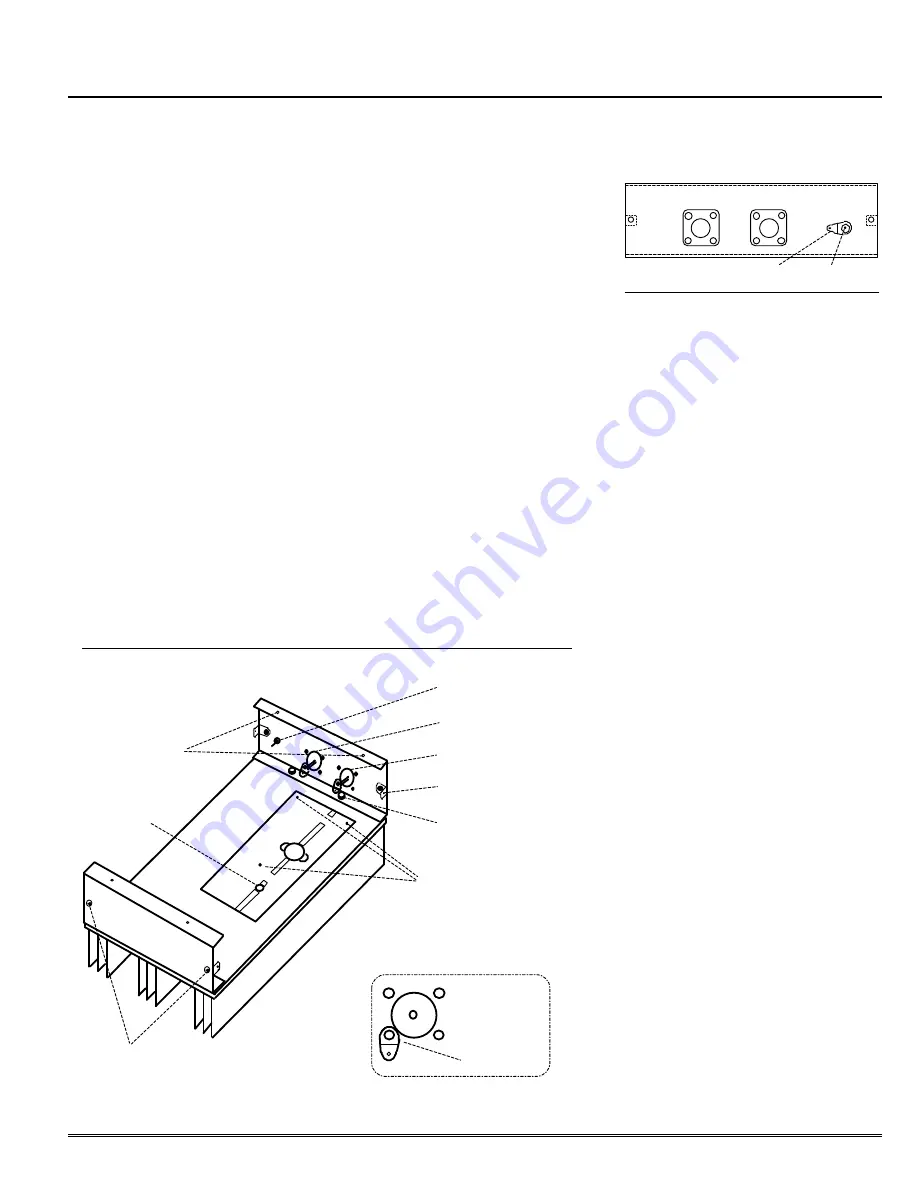

a. Set heatsink on bench, ori-

ented as in figure 1. Note where PA

transistor is to be mounted to two

adjacent holes. Align the pc board

with the heatsink, matching the cut-

out for the transistor and the pc

board mounting holes with the holes

on the heatsink.

Note that the heatsink

is used for several products; so there

will be extra holes to the left of the pc

board which are not used in this model.

b. Temporarily remove the pc

board, and lay it on a box or hold it in

a vise horizontally with the etched

side of the board up. Using a sharp

pick or any other convenient tool,

pick up eyelets and place them in the

small holes on the board. The heads

of the eyelets must rest flat against

the foil on the etched side of the

board. Then, using a small amount

of solder, solder the heads of the

eyelets to the foil. The eyelets con-

nect the pc board front and rear

ground planes together at critical lo-

cations. Be sure all small holes are

thus connected through. If you lose

an eyelet, bus wire can be used.

c. Turn the pc board over, and

solder the other side of the eyelets to

the ground plane. Be sure all are

soldered, and check to make sure

none have slipped back through the

other side. If so, heat eyelet flange

on top side of board until solder on

both sides melts, and push eyelet

gently back in place. Note that it is

especially important that the 8 eye-

lets under the emitter leads of Q1

are properly seated and that no sol-

der blobs protrude above eyelet

heads. This is to prevent stress on

transistor leads when it is later in-

stalled.

d. Set two #8 flat washers over

each of the 3 enclosure holes used to

mount the pc board (not the 2 tran-

sistor holes).

The two washers provide

the proper thickness for the pc board

spacing needed for the transistor; so be

sure to use the ones supplied to prevent

damage to the transistor.

Set the pc

board in place, and secure with three

each 6-32 x 3/8 inch thread cutting

screws. The screws go through the

pc board and spacer washers and

thread into the aluminum heatsink.

Be careful not to over tighten the screws

and strip the threads.

SOLDER LUG

FEEDTHRU CAP.

Figure 2. Outside View of End Plate.

J2 - OUTPUT

J1 - INPUT

C14 - PWR

e.

Locate the power transistor,

and note that the collector lead is

the narrow one (see component loca-

tion diagram). The collector lead

should face the right-hand side (to-

ward connectors). Apply a small

amount of heatsink compound to the

bottom surface of the transistor, and

set it in place through the cutout in

the board.

f. Secure the transistor with two

4-40 x 5/8 inch screws inserted

through the transistor flange into the

heatsink. Use lockwashers and nuts

on the fin side of the heatsink. Align

the transistor with the board before

tightening screws.

g. There are two end plates: one

has holes for connectors. Each end

plate has two clearance holes for at-

tachment to the heatsink and two

Pem nuts which allow the cover to be

secured. Position the end plate with

holes for connectors as shown, and

attach to heatsink with two 4-40 x

3/8 inch screws through the heat-

sink and two 4-40 nuts on the flange

of the end plate. In like manner, at-

tach the end plate without connector

holes on the other end of the heat-

sink. Before tightening screws, align

the end plates carefully with the

edges of the heatsink so the cover

later fits neatly.

h. The cover is secured to the

chassis with four angle brackets,

which are threaded on both sides but

have slightly different dimensions on

the two sides. It is important to in-

stall them correctly. These angle

brackets should be fastened to the

inside of the chassis as shown in the

diagram, using 4-40 screws. The leg

with the

shorter

dimension from the

bend to the hole goes over the screw,

HAMTRONICS® RPA-30 UHF REPEATER POWER AMPLIFIER

HAMTRONICS® RPA-30 UHF REPEATER POWER AMPLIFIER

ASSEMBLY, OPERATION, & MAINTENANCE INSTRUCTIONS

ASSEMBLY, OPERATION, & MAINTENANCE INSTRUCTIONS

Feedthru Capacitor C14

Input Connector J1

Output Connector J2

Angle Bracket (typical)

4-40 Nut with 4-40

Screw From Below

Be Careful Not To Remove These

Screws When Removing Cover.

Pem Nuts To

Attach Covers

Figure 1. Bottom View of Heatsink and End Plates

Note Position

of Solder Lug

on Connectors

Mounting Screws

Hole Not Used