©1995 Hamtronics, Inc.; Hilton NY; USA. All rights reserved. Hamtronics is a registered trademark. Revised: 1/31/00

- Page 3 -

workmanship problems. Double

check circuit to schematic diagram.

ALIGNMENT

CAUTION: Do not screw rotor screws

of piston capacitors down so far that they

touch the pc board under the body of the

capacitor.

Doing so would cause a

short circuit and possibly cause dam-

age. The screw bottoms out when

the top of the screw protrudes less

than about 1/4 inch from the top of

the capacitor.

a. Preset the variable capacitors

as follows:

•

Mica capacitor C12: 1 turn from full

clockwise.

•

Piston capacitor C1: 5/16 inch of

screw exposed.

•

Piston capacitor C2: 3/16 inch of

screw exposed.

•

Piston capacitor C13: 1/2 inch of

screw exposed.

b. Connect J1 to repeater output

or other source of 10 Watts drive.

Connect J2 through power meter to a

good uhf 50 ohm dummy load.

c. Connect reg13.6Vdc

power source to feedthru capacitor

C14 and power supply ground to adja-

cent ground lug. (If your power sup-

ply has adjustable voltage, it is better

to start tuning with about 10Vdc and

increase it to 13.6 Vdc after you de-

termine there are no problems.)

Note: Do not retune repeater output

stage or other driving source with RPA-

30 connected.

Driving source should

be tuned into 50 ohm load and left

alone afterwards. Input of RPA-30 is

tuned then to present 50 ohm load to

driver.

d. Apply drive to PA, and alter-

nately adjust C1, C2, C12, and C13

for maximum output. Do this several

times to work out any interactions.

Use an insulated tool with a small

metal screwdriver bit in the end.

e. When fully tuned, the PA

should deliver about 30 to 45 Watts

with 9-11 Watts drive when using a

13.6Vdc power supply. If the dc volt-

age is low, the output will be less.

You may also experience consider-

able loss in the output coax if it is not

a good low-loss uhf type. The PA will

draw about 6 to 7 Amp at full output.

Note: It is normal for C12 to be near

full clockwise and C13 to be near mini-

mum capacitance (screw exposed about

1/2 inch) when operating into a 50 ohm

load at 445 MHz.

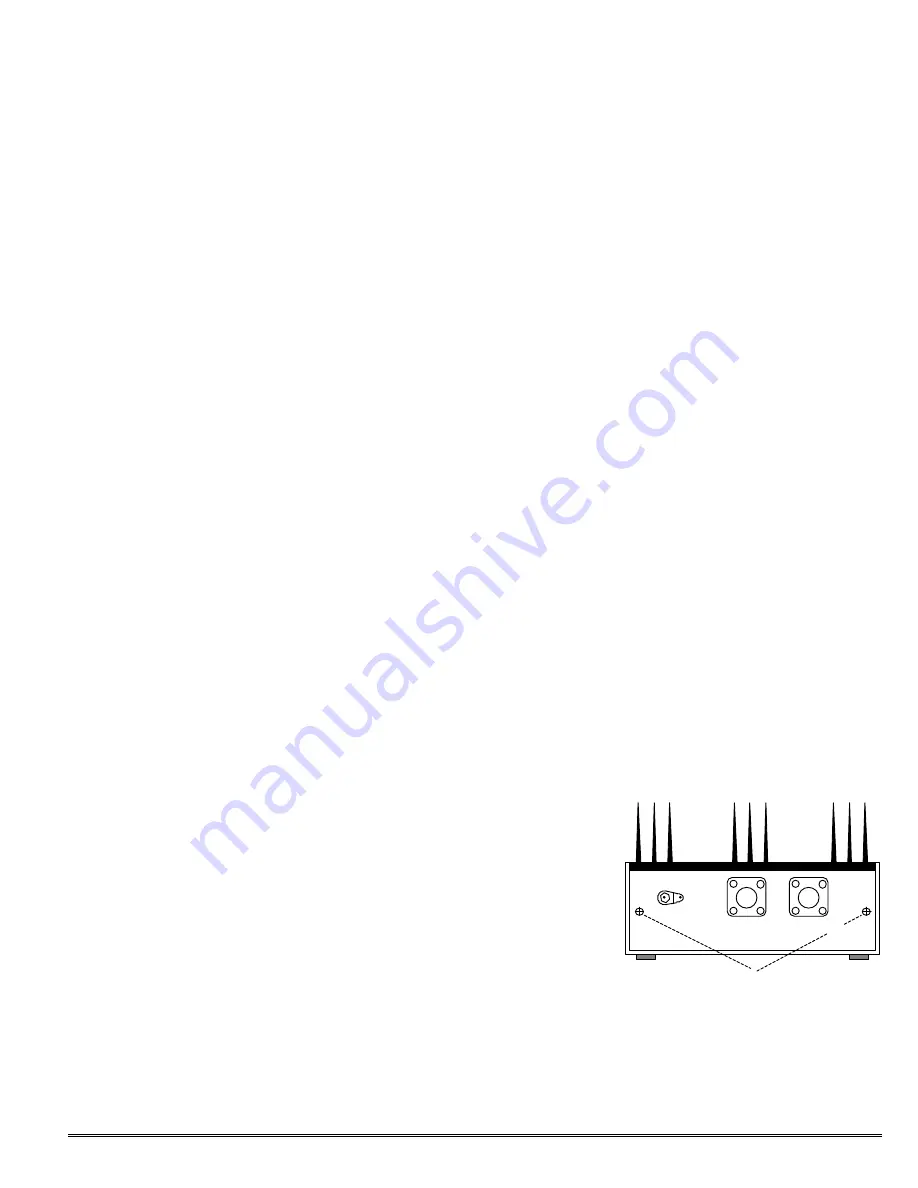

COVER.

The cover slides over the PA as-

sembly and is secured to the Pem

nuts and angle brackets on the end

plates, using eight 4-40 x ¼ inch

screws. Tighten the screws on the

bottom first to draw the cover down

tight, and then tighten the screws on

the sides. The four rubber feet

should be stuck in place about ½

inch in from each corner on the bot-

tom of the cover. If you remove the

cover for service, be careful not to in-

advertently loosen the screws on the

outside surface of the end plates

which attach the angle brackets to

the end plates.

MOUNTING.

There are several ways to install

the RPA-30, none of which is critical

as long as air flow is not restricted

around fins. The simplest is merely

to set the PA, fins up, on a shelf near

the repeater. If you wish to mount

the PA to a blank rack panel or other

vertical surface, such as a cabinet

wall, simply drill a few holes in the

cover and mount the cover. Then,

slide the PA assembly into the cover,

and secure with eight 4-40 x ¼ inch

screws. (The cover must be installed

to prevent repeater de-sense.)

POWER.

The RPA-30 requires well-

regulated 13.6Vdc, free of transients,

at about 6 to 7 Amp. An 8 Amp con-

tinuous-duty power supply would

have some reserve. Use fairly short,

heavy leads to connect positive to

feedthru capacitor and negative to

adjacent ground lug. If there are any

relays or other inductive devices on

the same power supply, be sure to

put a reverse diode across the device

to absorb reverse voltage spikes gen-

erated by inductive kick-back. It

would be wise to connect an 8 Amp,

fast-acting fuse in series with the PA

power lead if the power supply is ca-

pable of more than 8 Amps.

CAUTION: RF power transistors are

fully tested by the manufacturer and are

not guaranteed because they are easily

damaged by physical or electrical abuse.

They are very expensive to replace. Be

sure to use adequate precautions to avoid

damage.

OPERATION.

Once tuned, the PA will automati-

cally operate when sufficient drive is

applied. Since it operates class C, it

will draw no current when no rf

power is applied. It is designed for

continuous duty at up to 45 Watts.

Do not operate it above that level.

Reduce drive if necessary so it will

operate at this level, which is suffi-

ciently conservative if heatsink is not

blocked and ambient temperature is

below 100 degrees F.

REPAIR.

Should it be necessary to replace

the transistor, be sure to use an ex-

act replacement. To remove old

transistor, carefully peel each lead

away from the pc board while appl y-

ing heat to melt solder. Then, re-

move transistor from unit, and clean

excess solder from board. This is im-

portant to avoid tearing leads from

new transistor when hardware is

tightened. Also, clean off old heat-

sink compound, which may be dirty,

and apply a fresh coat to the new

transistor. Remember to resolder

any components removed for access

to transistor.

C14 - POWER

J2 - RF OUTPUT

Figure 3. PA in Operating Position

Do Not Remove These Screws

J1 - RF INPUT