HAMWORTHY HEATING LTD

12

PUREWELL

Vari

Heat c

500001169/T

Open Vented sytems

Boilers must not be capable of isolation from the vent pipe. Valves between boiler and vent pipe to be three way

type such that when boiler is isolated from vent pipe it is open to atmosphere. Safety valves should either be

mounted on the boiler by using the connection provided, or it should not be possible to isolate a safety valve

common to more than one boiler from each boiler. BS6644 provides details.

Sealed Systems

A boiler must not be capable of isolation from the individual or common safety valve. Valves between boiler and

common safety valve to be three way type such that when boiler is isolated from safety valve it is open to

atmosphere. The boiler is provided with a connection on the boiler for the safety valve .

Where using Hamworthy Heating Ltd pipework kits, assembly of these is detailed in the Instruction manual

supplied with kit.

5.3 Electrical Connections:

The following electrical connections are provided on each module on a rail at the base of the front of the boiler.

Supply: Live, Neutral and Earth. See Section 4.6 for details.

Live and Neutral connections for Shunt pump or Primary Pump

Boiler Overheat Fault Alarm Signal Output

Common Fault Alarm Signal Output

Boiler Normal Run Signal Output

Remote On/Off

0-10v Analogue Control Signal Input

External sensors

Cascade Management of Multiple Boiler Installations with Merley sequence controller.

5.0 BOILER ASSEMBLY

General

Boilers are despatched to site as fully assembled units. The flue pipe, chimney, condensate drain connection and

pipework manifold set (where applicable) are the only items that will need assembling on site.

During assembly it is important to take care to prevent damage to the boiler casing. DO NOT STAND ON THE

CASING PANELS.

Boiler positioning must allow the minimum clearances detailed in Section 3.0 to facilitate access for flue and

pipework connections as well as maintenance. Boilers can be positioned side by side, no clearance is necessary.

5.1 Flue Pipe

So as to avoid damage, the flue connecting pipe is supplied separately.

Fit the elbow to the base of the boiler and secure using the gasket and 4 - M8 nuts and washers. Moisten the lip

seal and engage the flue pipe into the elbow. Secure the flue pipe to the boiler casing using the bracket supplied.

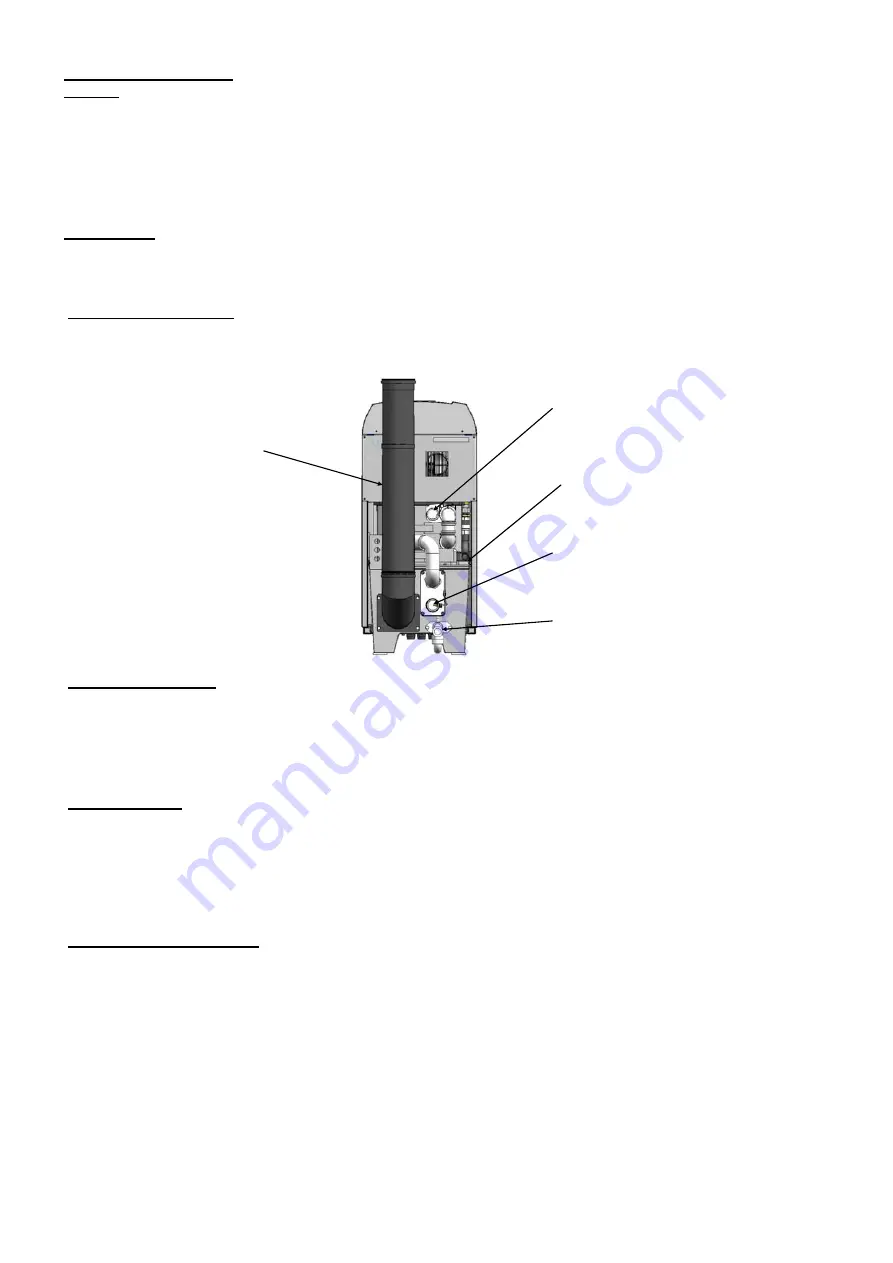

5.2 Water Connections:

Connecting pipework must be self-supporting to avoid stress on the boiler connections. Local unions are

recommended in the pipework to facilitate future servicing requirements.

Figure 5.2.1 - Rear Water Connections

Rp1”

Safety Valve

(behind flue pipe)

Flow R2” Male thread. Indicated by a

red dot on boiler.

Return R2” Male thread. Indicated

by a blue dot on boiler.

Gas R1” Male thread.

Condense 32mm dia. Male plain. Offset

and below return connection.

Summary of Contents for Purewell VariHeat 70c

Page 2: ......

Page 43: ...HAMWORTHY HEATING LTD 37 PUREWELL VariHeat c 500001169 T Figure 8 3 11 Operating phases ...

Page 44: ...HAMWORTHY HEATING LTD 38 PUREWELL VariHeat c 500001169 T Figure 9 0 Boiler Wiring Schematic ...

Page 65: ...HAMWORTHY HEATING LTD 59 PUREWELL VariHeat c 500001169 T Figure E1 2 Typical Piping Layouts ...

Page 70: ...HAMWORTHY HEATING LTD 64 PUREWELL VariHeat c 500001169 T NOTES ...

Page 71: ......