HAMWORTHY HEATING LTD

57

PUREWELL

Vari

Heat c

500001169/T

APPENDIX D - VENTILATION

D1.1 Air Supply

Detailed recommendations for air supply are given in BS 6644. The following notes are intended to give general

guidance. In all cases there must be provision for an adequate supply of air for both combustion and general

ventilation, in addition to that required for any other appliance.

Combustion air for the boiler is drawn through the rear of the boiler casing. The area

must

be kept open and free

from blockage at all times.

D1.2 Air Supply by Natural Ventilation

The boiler room must have, or be provided with, permanent air vents directly to the outside air, at high level and at

low level. For an exposed boiler house, air vents should be fitted, preferably on all four sides, but at the least on

two sides. Air vents should have negligible resistance and must not be sited in any position where they are likely

to be easily blocked or flooded or in any position adjacent to an extraction system which is carrying flammable

vapour. Grilles or louvres must be so designed that high velocity air streams do not occur within the space

housing the boiler.

The air supplied for boiler house ventilation shall be such that the maximum temperatures within the boiler house

shall be as follows;

1) At floor level (or 100mm above floor level) = 25°C

2) At mid-level (1.5m above floor level) = 32°C

3) At ceiling level (or 100mm below ceiling level) = 40°C.

Where both low and high level openings are used, the grilles shall have a total minimum free area of:

Low level (inlet) - 4.0 cm² per kilowatt of total rated net heat input.

High level (output) - 2.0 cm² per kilowatt of total rated net heat input.

If the boilers are to operate during the summer months for 75% of the time a further 1 cm² or for 100% of the time

a further 2 cm² should be added per kW to both high & low openings.

D1.3 Air Supply by Mechanical Ventilation

Air supplied to the boiler room by Mechanical means should be as follows:

1) Mechanical ventilation must be interlocked with the boilers to prevent operation in

the event of ventilation fan failure

2) Mechanical inlet and mechanical extract can be utilised providing the design

extraction rate does not exceed one third of the design inlet rate.

3) Mechanical extract ventilation with natural inlet ventilation

MUST NOT

be used.

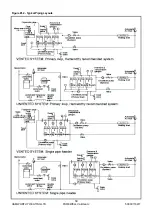

Figure D1 Mechanical Ventilation Flow Rates

Flow rate per kW total

rated heat input (net)

Inlet air

(Combustion

ventilation)

Difference between

inlet and extract air

(Inlet minus extract

ventilation)

m³/h

m³/h

Volume

2.6

1.35 +/- 0.18

Boilers

Without

Draught

Diverters

Summary of Contents for Purewell VariHeat 70c

Page 2: ......

Page 43: ...HAMWORTHY HEATING LTD 37 PUREWELL VariHeat c 500001169 T Figure 8 3 11 Operating phases ...

Page 44: ...HAMWORTHY HEATING LTD 38 PUREWELL VariHeat c 500001169 T Figure 9 0 Boiler Wiring Schematic ...

Page 65: ...HAMWORTHY HEATING LTD 59 PUREWELL VariHeat c 500001169 T Figure E1 2 Typical Piping Layouts ...

Page 70: ...HAMWORTHY HEATING LTD 64 PUREWELL VariHeat c 500001169 T NOTES ...

Page 71: ......