HAMWORTHY HEATING LTD

14

PUREWELL VariHeat he

500001155/F

7.0 CHECKS PRIOR TO LIGHTING

IMPORTANT: BEFORE PROCEEDING TO LIGHT THE BOILER, ENSURE THAT THE PRE-

COMMISSIONING CHECKS HAVE BEEN CARRIED OUT AND THE RESULTS SATISFACTORY.

7.1 Boiler Gas System Leak Check

Ensure that the appliance manual gas service valve is in the OFF position. Although the boiler receives a gas

leak check and gas train component integrity check prior to leaving the factory, transport and installation may

have caused disturbance to unions.

A procedure guide is given below. Care must be taken not to allow leak detection fluid on or near any electrical

parts or connections.

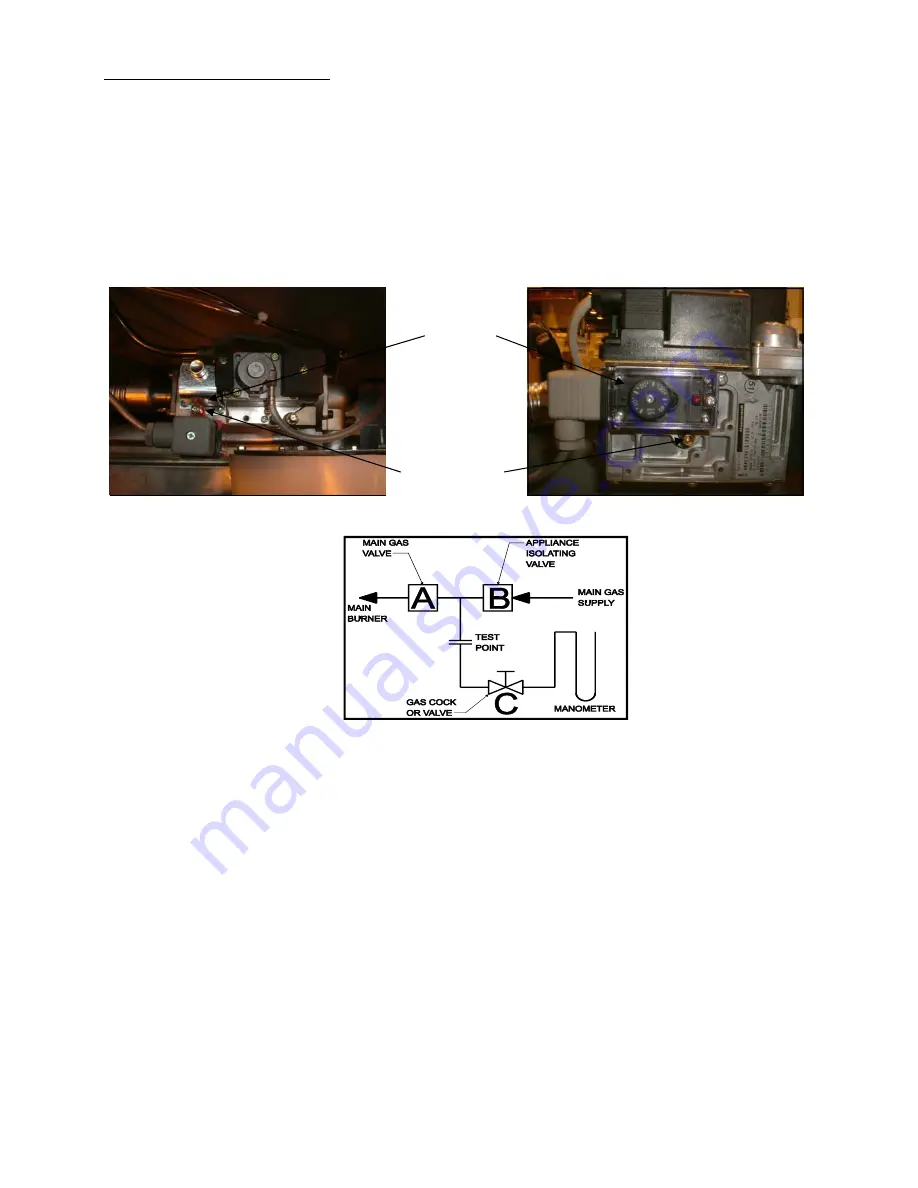

Figure 7.1.2 - Gas System Leak Check Diagram

Note: -

Main gas supply pressure - G20 - 20mbar

To Check Valve B

1) Turn off the electrical power and gas to the appliance.

2) By unscrewing screw at Position X of Figure 7.1.1 remove the red gas pressure switch (L.H.S picture) or loosen

the test point valve plug (R.H.S picture).

3) Connect the manometer to gas valve test point.

4) With A, B closed open C and monitor manometer over a 2 minute period, a rise indicates a leak on valve B.

5) Reinstall red gas pressure switch or shut valve plug in test point.

To Check Valve A

1) Repeat steps 1, 2, 3 & 5 above.

2) Open C.

3) Open B to produce the main gas supply pressure between A and B.

4) Close B

5) System may be considered sound if over a period of 2 minutes any drop in pressure is less than 0.5 mbar

(0.2" wg.).

NOTE:

Allow a manometer stabilisation period of approximately 1-minute before each 2 minute check period. Fol-

lowing soundness tests close valve B and remove manometer connections and tighten test points.

Figure 7.1.1 - Test Point Locations On Gas Valves

Position X

(Test Point)

Low Gas

Pressure

Switch