HAMWORTHY HEATING LTD. PUREWELL AUTOMATIC IGNITION 500001035/G

7

8.0

WATER CIRCULATION SYSTEM

8.1

General

The Purewell Cast Iron Boiler has a low water content

and the requirements of minimum water flow are given

in

Section 8.8: Minimum Water Flow Rates

and

Figure No. 2. Recommendations for the water

circulation system are given in

BS 6644

and

CP 342

.

The following notes are of particular importance: -

1)

In a combined central heating and hot water system,

the hot water storage vessel must be of the indirect

cylinder or calorifier type. The hot water storage vessel

should be insulated preferably with not less than 75mm

(3 in) thick mineral fibre, or its thermal equivalent.

2)

Circulating pipework not forming part of the useful

heating surface should be insulated to help prevent

heat loss and possible freezing, particularly where

pipes are run through roof spaces and ventilated

cavities. Cisterns situated in areas, which may be

exposed to freezing conditions, should also be

insulated. Insulation exposed to the weather should

be rendered waterproof.

3)

Draining taps must be located in accessible

positions which permit the draining of the whole

system, including the boiler and hot water storage

vessel.

4)

Each boiler has one 2" BSP female flow and one

2" BSP female return tapping. Flow and return

headers should connect boilers but sufficient length

of connecting pipe should be allowed to clear the

casing before connecting into the headers. The

headers should be connected to the system in a

“reverse return” arrangement (the water flow in each

header is in the same direction) to ensure equal flow

in each module. Figure No. 8 shows typical layout.

8.2

Pressure Relief Valve (Safety Valve)

Each boiler, or in the case of a modular installations,

each bank of boilers, must be fitted with a pressure

relief valve to

BS 759

or

BS 6759

Part 1(

ISO 4126

)

and sized as shown in

BS 6644

.

BS 6644

provides comprehensive information for the

selection and location of safety valves and attention

is drawn to the higher capacity requirements of safety

valves for pressurised hot water systems.

8.3

Open Vent and Cold Feed Pipe

(See

BS 6644

for further information.)

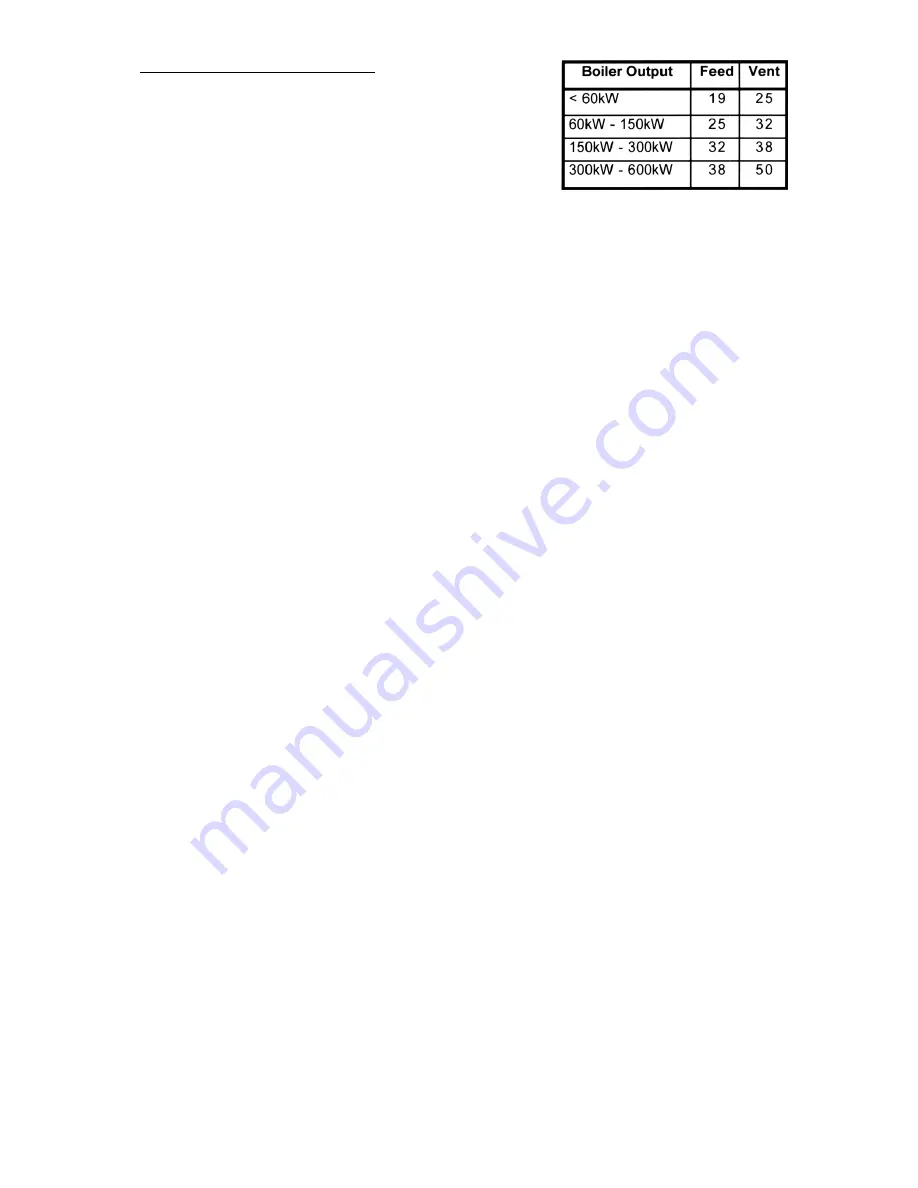

Every boiler or group of boilers should have an open

vent pipe and cold feed pipe installed between the

boiler and the first water isolating valve. The minimum

bore (mm) of these pipes per installation is as follows:-

The vent pipe must rise continually, it must not be

valved except by a design which when closed for

maintenance ensures the boiler is open to

atmosphere. The pipe shall be protected against

freezing where this might occur.

8.4

Altitude Gauge (Water Pressure Gauge)

Every boiler or group of boilers should be provided

with a gauge complete with isolating cock. See Figure

No. 8 for typical position.

8.5

Thermometer

See Figure No. 8 for typical position. A thermometer

complete with pocket should be fitted in the pipework

to indicate water flow temperature.

8.6

Drain Valves

Each boiler should have a

1

/

2

” NB drain valve (not

H.H.L. supply) fitted to drain the boiler only. The

heating system in total should have drain valves as

recommended by

BS 6644

. See Figure No. 8 for

recommended positions.

8.7

Circulating Pump

One or more circulating pumps will be required to

circulate water around the boilers and heating system.

Figure No. 1 shows the hydraulic resistance of the

boiler. The pump should be sited to facilitate servicing.

It is important to note that when Purewell boilers are

used to replace boilers on an existing system, the

pumps should be checked for performance against

the new boiler waterside pressure drop to ensure that

the minimum flow rate can be obtained. It is also

important that the existing system be flushed through

twice to remove any loose matter, which may have

accumulated. If in any doubt regarding the cleanliness

of the system, a coarse filter should be fitted in the

return pipework to the boilers.

8.8

Minimum Water Flow Rates

Minimum water flow rates are shown in Figure No. 2.

These flow rates should be maintained through the

boiler at all times whilst the boiler is firing. If the water

flow rate is allowed to fall below the minimum, the

boiler heat exchanger could fail due to the resultant

scale formation. Particular attention should be paid

to the restriction of external flow circuits during periods

of low heat demand.