HAMWORTHY HEATING LTD. PUREWELL AUTOMATIC IGNITION 500001035/G

3

The installation should also be in accordance with

any relevant requirements of the local gas region and

local authority and the relevant recommendations of

the following documents: -

British Standards

BS 7074:

Application, selection and installation of

expansion vessels and ancillary equipment for sealed

water systems. Part 2: Code of practice for low and

medium hot water systems.

BS 6891:

Installation of low-pressure gas pipework

of up to 28mm in domestic premises. (For larger

installations see

IM/2

,

IM/5

and

IM/16

below.)

BS 6644:

Installation of Gas Fired Hot Water Boilers

- 60kW to 2MW.

BS 6700:

Design, installation, testing and

maintenance of services supplying water for domestic

use.

BS 6880:

Part 1, 2 & 3:

Code of practice for low

temperature hot water heating systems of output

greater than 45kW.

BS EN 60335, Part 1.

Safety of Household &

Similar Electrical Appliances.

BS 3456, Part 201:

Electrical Standards.

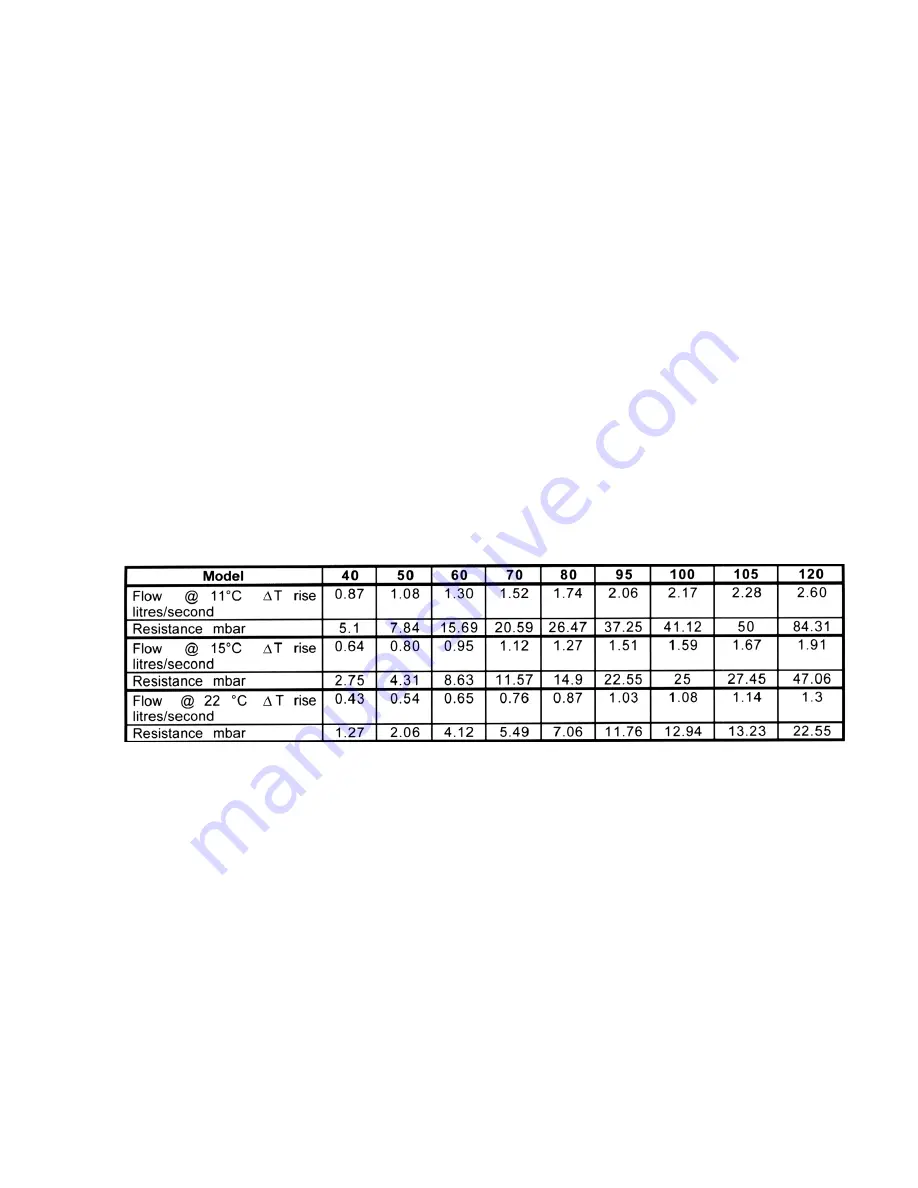

Figure No. 2 - Flow-rate/Pressure Drop Table

CP 342:

Centralised hot water supply.

Part 2: Buildings other than individual dwellings.

British Gas Publications

IM/2

Purging procedures for non-domestic gas

installations.

IM/5

Soundness testing procedures for industrial and

commercial gas installations.

IM/11

Flues for commercial and industrial gas fired boilers

and air heaters.

IM/16

Guidance notes on the installation of gas pipework.

(Excluding domestic installations of 25mm and below.)

Health and Safety Executive:-

Guidance note PM5

- Automatically controlled steam and

hot water boilers.

CIBSE Publications: -

“CIBSE Guide”

It is impractical in this document to specify all relevant

information, but the following extracts from the above

references are emphasized since failure to comply with

these requirements will almost certainly result in an

unsatisfactory installation.

3.2

Feed water Quality

If the boiler feed water has a high degree of hardness,

it is recommended that the water be treated to prevent

precipitation of scale or sludge in the boiler water

passageways. Details of additives can be obtained

from any reliable manufacturer of water treatment

products or the local water authority. It should be

noted however, that even if the boiler water is of

average hardness, not requiring treatment,

subsequent draining of the system for repair or

constant make-up water due to an undetected leak

will cause additional deposits and gradual build-up of

scale. It is essential, therefore that leaks are attended

to promptly and draining is kept to an absolute

minimum.

It is recommended that the system is flushed out at

least twice with hot water before any treatment is

added. If any doubt exists regarding the

It is recommended that the system is flushed out at least

twice with hot water before any treatment is added. If any

doubt exists regarding internal cleanliness of an old

system, consideration should be given to the fitting of a

coarse filter in the return pipework to the boilers.

3.3

Adequate Water Flow

The Hamworthy Purewell boiler is designed as a quick

response, low water content unit, to run continuously with

maximum reliability. Care should be taken in the initial

design and layout having due regard for adequate water

flow through the boilers and the influence of the system

controls.

NOTE!

The Standards Authority recommend a

minimum return temperature of 50

°

C in all heating

systems other than condensing boilers.

Figure No. 2 shows recommended and minimum water

flows required. The control system and valves, where

fitted, should be regulated to avoid lower flows occurring.