HAMWORTHY HEATING LTD

SHERBORNE

500001103/E

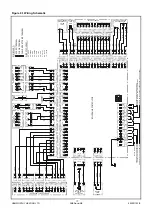

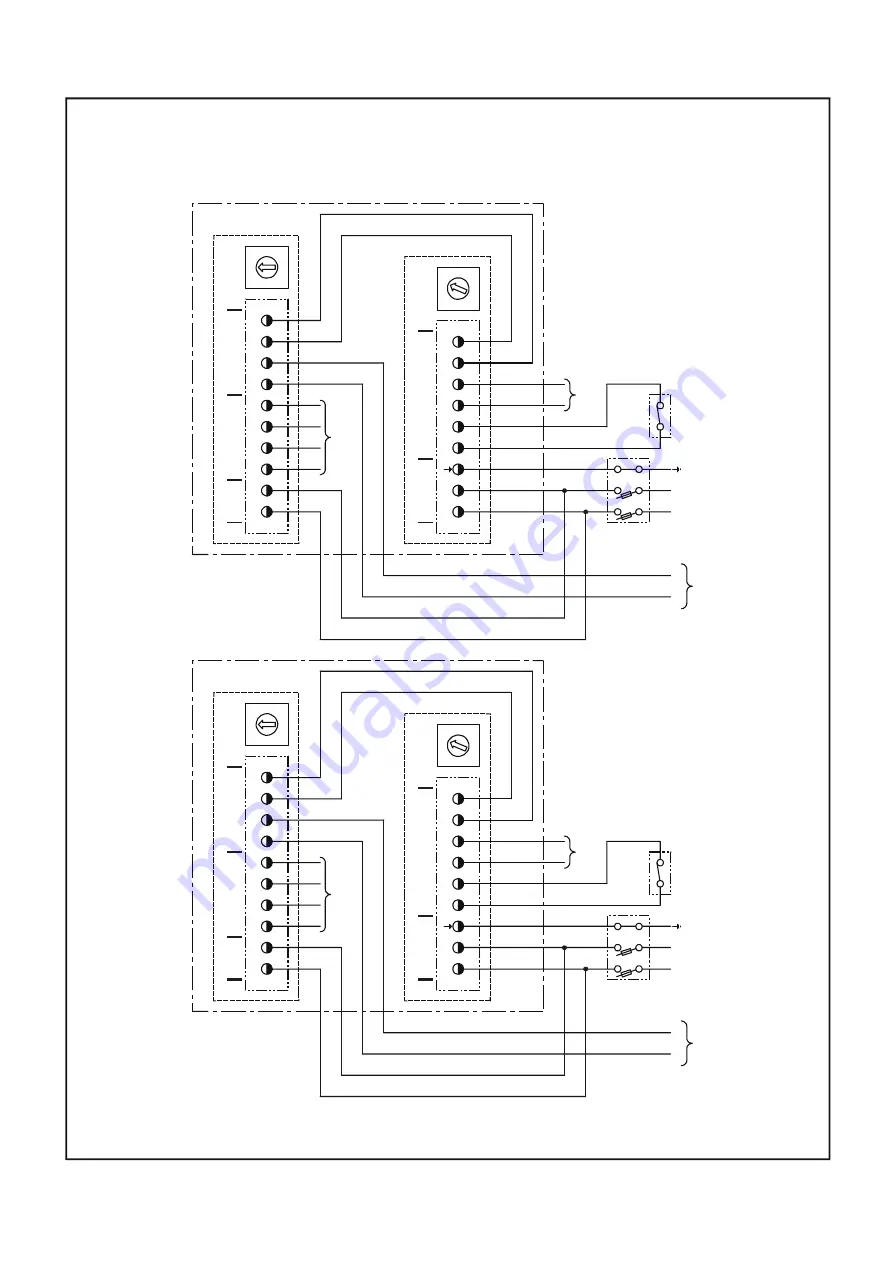

Figure 8.12 Site Wiring Diagram (Page 2 of 2)

L

L

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

N

N

R1

R1

R2

R2

R3

R3

R4

R4

S1

S1

S2

S2

4

4

4

4

3

3

3

3

2

2

2

2

1

1

1

1

0

0

0

0

F

F

F

F

E

E

E

E

D

D

D

D

C

C

C

C

B

B

B

B

A

A

A

A

9

9

9

9

8

8

8

8

7

7

7

7

6

6

6

6

5

5

5

5

BO

IL

ER

SI

TE

W

IR

IN

G

T

ER

M

IN

AL

S

BO

IL

ER

SI

TE

W

IR

IN

G

T

ER

M

IN

AL

S

IN

TE

RF

AC

E M

O

DUL

E S

IT

E

WIRI

NG

T

ERM

INA

LS

BRO

W

N CO

RE

BR

O

W

N CO

RE

BL

U

E CO

RE

BL

UE

CO

RE

IN

TE

RF

AC

E M

O

DU

LE

S

IT

E

W

IRIN

G

T

ER

M

IN

AL

S

FU

SED

ISOLA

TOR

FU

SED

ISOLA

TOR

L

L

GN

D

GN

D

N

N

SI

G

SI

G

230V

A

C

50H

z

230V

A

C

230V

A

C

230V

A

C

50H

z

LO

W V

O

LT

AG

E CO

NT

RO

L

LO

W

V

O

LT

AG

E

LOW

V

O

LT

AG

E

LO

W

V

O

LT

AG

E

CO

NT

RO

L

0-10V

A

N

AL

O

G

U

E

0-

10V

A

N

AL

OGU

E

SU

PP

LY

SU

PP

LY

SU

PP

LY

SU

PPL

Y

SI

G

N

AL

IN

PU

TS

IN

PU

TS

/O

U

TPU

TS

IN

PU

TS

/O

U

TPU

TS

SI

G

N

AL

IN

PU

TS

CO

NT

RO

L INP

U

T

CO

NT

RO

L IN

PU

T

RO

TA

RY

SW

IT

C

H -

SW

1

RO

TA

R

Y

SW

IT

CH -

S

W

1

RO

TA

RY

SW

IT

CH -

S

W

1

RO

TA

RY

SW

IT

CH

- SW

1

BO

IL

ER

M

O

DUL

E NUM

BE

R

1

BO

IL

ER

M

O

DU

LE

NUM

BE

R 2

SE

Q

U

EN

CI

N

G

INT

ER

FA

C

E

M

O

DUL

E

SE

Q

UE

NCIN

G

IN

TE

RF

AC

E

M

O

DUL

E

BO

IL

ER

M

AI

N

C

O

N

TR

O

L P

C

B

BO

IL

ER

M

AI

N

C

O

N

TR

O

L

PC

B

CO

NT

AC

T T

ERM

IN

AL

S

CO

NT

AC

T T

ERM

IN

AL

S

N

O

TE

: VO

LT

F

REE

N

O

TE

: V

O

LT

FR

EE

NO

T

UT

IL

IS

ED

NO

T

UT

IL

IS

ED

NO

T UT

IL

IS

ED

NO

T UT

IL

IS

ED

CO

NT

RO

LS

CO

NT

RO

LS

IN

TE

R

LO

C

K

INT

ERL

O

C

K

SA

FE

TY

SA

FE

TY

NO

T S

H

O

W

N

FO

R

NO

T S

H

O

W

N F

O

R

CL

AR

IT

Y

CL

AR

IT

Y

4) MULTIPLE BOILER INSTALLATION, FULLY MODULATING SEQUENCED OPERATION VIA 0-10V ANALOGUE CONTROL SIGNALS FROM A NON HAMWORTHY HEATING LIMITED BOILER

SEQUENCE CONTROL SYSTEM, UTILISING OPTIONAL HAMWORTHY HEATING LIMITED SEQUENCING INTERFACE MODULES.

NOTE: ROTARY SWITCH 'SW1' ON BOILER CONTROL PANEL MAIN PCB - POSITION '1' SETS BOILER TO REMOTE FULLY MODULATING SEQUENCED OPERATION. ROTARY SWITCH ‘SW1’

ON SEQUENCING INTERFACE MODULE PCB - POSITION ‘0’ FOR 0-10V ANALOGUE CONTROL SIGNAL OPERATION.

16

Summary of Contents for Sherborne S65

Page 8: ...HAMWORTHY HEATING LTD SHERBORNE 500001103 E Figure 1 1 Boiler Installation Typical 2 ...

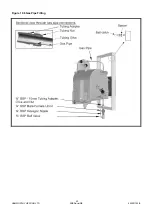

Page 29: ...HAMWORTHY HEATING LTD SHERBORNE 500001103 E Figure 10 6 Gas Pipe Fitting 23 ...

Page 45: ...HAMWORTHY HEATING LTD SHERBORNE 500001103 E NOTES 39 ...

Page 46: ...HAMWORTHY HEATING LTD SHERBORNE 500001103 E NOTES 40 ...

Page 47: ...Notes ...