HAMWORTHY HEATING LTD

SHERBORNE

500001103/E

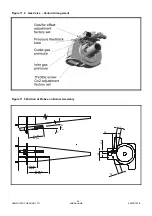

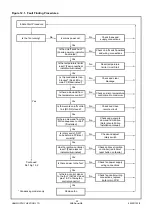

Figure 10.3.3 Connection of Flue System

(Separate Ducts

)

Appliance connector

90° support elbow

Mounting bracket

Flue elbow

Air inlet box

ø80/100 eccentric

ø100 Flue

adapter

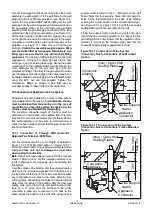

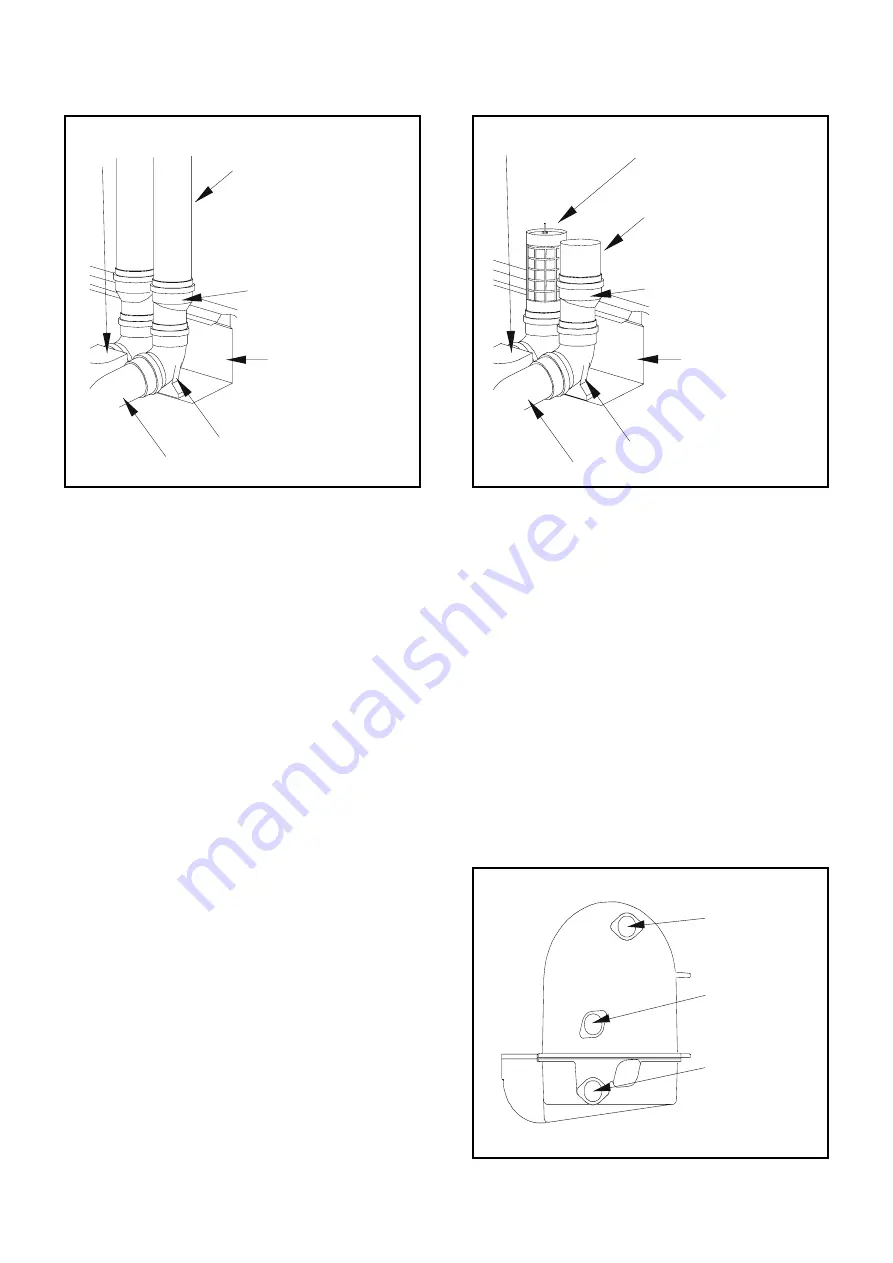

10.3.4 Connection of Single Pipe Horizontal/

Vertical Open Flue – 100mm

Note:

the flue support cradle is not required for this

installation and should be discarded.

Refer to Figures 6.1.4 and 10.3.4. Secure the flue

elbow mounting bracket to the wall frame using 3 –

M6 nuts and washers. Locate the 90°-discharge

elbow onto the right hand mounting bracket lug and

fit the appliance connector duct between the flue

outlet in the aluminium boiler casing and the 90°

elbow. The vertical leg of this duct is telescopic to

assist with installation. Locate the air inlet terminal

into the left hand 90° elbow. Fit the remaining flue

components on route to the terminal discharge

ensuring a minimum 2° slope and that the flue

system is self supporting using wall brackets where

necessary. In terminating the flue system, ensure

that the joint through the wall / roof is made good

and weatherproofed. The top of the plastic boiler

cover has a D shaped recess that marks the

position of the vertical flue exit point. Using a

suitable fine toothed hacksaw or jigsaw, carefully cut

around the inside of the recess to provide the flue

outlet.

Having fitted the flue system to the boiler, carefully

refit the burner assembly and secure to the heat

exchanger using the 2 – M6 nuts previously

removed taking care not to damage the probes or

the burner flange gasket see Figure 10.2.

Reconnect the pressure feedback tube to the gas

valve.

Figure 10.3.4 Connection of Single Pipe (Open Flue)

Air inlet

Flue elbow

90° support elbow

Mounting bracket

Appliance connector

ø80/100 eccentric

adapter

ø100 Flue

Air inlet box

terminal

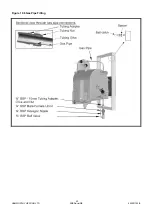

10.4

Water Connections

See Figure 10.4. Care must be taken when installing

water system pipework that undue stress is avoided

on the boiler flow and return connections. It is

recommended that unions are fitted local to the

boiler and outside of the casing, to permit future

servicing requirements. Fully closing valves must

not be connected to both flow and return pipes

unless the boiler is fitted with an individual, correctly

sized and positioned safety valve. It is

recommended that a 3-way 'T' port valve is fitted in

the flow connection to allow an open vent situation

should the boiler need to be fully isolated from the

system.

To ensure that the flow and return pipework are

retained within the boiler casing,

it is

recommended that swept bends are not used.

To

achieve this use 1

1/4

” elbows or tees.

Figure 10.4 Water Connections

Flow

Return

Return

S65 Model

S70c Model

21

Summary of Contents for Sherborne S65

Page 8: ...HAMWORTHY HEATING LTD SHERBORNE 500001103 E Figure 1 1 Boiler Installation Typical 2 ...

Page 29: ...HAMWORTHY HEATING LTD SHERBORNE 500001103 E Figure 10 6 Gas Pipe Fitting 23 ...

Page 45: ...HAMWORTHY HEATING LTD SHERBORNE 500001103 E NOTES 39 ...

Page 46: ...HAMWORTHY HEATING LTD SHERBORNE 500001103 E NOTES 40 ...

Page 47: ...Notes ...