HAMWORTHY HEATING LTD

SHERBORNE

500001103/E

the controls panel to the heat exchanger, remove the

controls panel and locate it on the left hand cover

support bracket on the bottom of the wallframe.

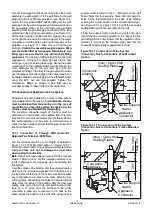

5)

Disconnect the pressure feedback tube from the

gas valve. Remove the 4xM5 screws/nuts securing

the fan/venturi/gas valve assembly to the transition

duct.

Note

the use of a spacer on the screw/nut

nearest to the heat exchanger casting. Withdraw the

assembly from the air inlet duct. Remove the 2xM5

screws securing the venturi/gas valve assembly to

the fan. Clean the fan impellor and venturi tube with a

soft brush if necessary.

6)

Remove the 2 – M6 nuts securing the burner

assembly to the front of the heat exchanger – see

Figure 11.1 and carefully remove the burner

assembly, taking care not to damage the probes or

burner.

7)

Remove the single socket cap head screws

securing the igniter and flame probe to the burner

flange. Carefully withdraw the igniter and probe.

Remove the loose flange and Mica sight glass noting

the position for re-assembly. Check condition of the

igniter assembly and probe for damage, clean or

replace as required.

8)

Remove the 2 x M6 nuts securing the transition

duct to burner and separate the components.

9)

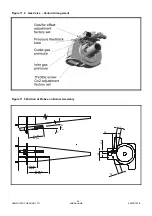

Check the burner and clean using a soft brush if

required (if possible use compressed air to blow out

the dust inside the burner tube). Alternatively the

burner tube can be washed using a soapy water

solution. Tap the burner flange firmly downwards on

a block of wood to dislodge any residual debris from

inside the burner tube. A damaged burner should be

replaced. (Fit the igniter and probe to the burner

flange to check the respective positions - See Figure

11.5)

Re-assemble in reverse order checking the condition

of gaskets and replace if necessary.

Refer to

Section 11, Commissioning and Testing

,

and test all gas joints broken or disturbed for

soundness before firing.

Carry out a combustion check by testing the flue gas

CO

2

and CO levels as detailed in

Section 11

.

4

.

13.3 Two Year Service

Repeat the annual service as previously described

but do not refit any components to the heat

exchanger.

To clean the heat exchanger, either ;

the sump must be removed. In the case of the S70C

model this requires the boiler to be isolated from the

system and drained down.

Or the heat exchanger must be removed from the

aluminium casing, having isolated the boiler from the

system and drained down. This is best achieved by

lifting the boiler module off the wall plate. Go to

Section 13.3.2.

13.3.1

Disengage the appliance flue connector from

the sump casting. Remove the 2xM6 screws securing

the condense trap to the sump and disconnect the

section of pipe routed back to the wall frame.

S65 Model

– support the sump from underneath and

remove the 4xM6 securing nuts. Lower the sump

casting to expose the heat exchanger and baffles.

S70C Model

- having drained the system down,

remove the return (lower) connection and heat

exchanger connecting pipe from the rear of the boiler

secured by M8 nuts and washers – see Figure 10.4.

Note

, there is an ‘O’ ring used on each fitting.

Support the sump from underneath and remove the

4xM6 securing nuts. Lower the sump casting and

secondary heat exchanger assembly to expose the

heat exchanger and baffles.

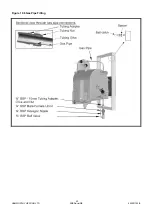

To clean the heat exchanger(s), the use of a high

pressure water hose (40-80 psi) is recommended

with the resultant discharge being collected in a

suitable receptacle.

Primary Heat Exchanger -

using the high pressure

hose, insert the cleaning nozzle into the burner

opening. Switch on the pump and traverse the full

length and circumference of the heat exchanger to

remove any deposits

Condensing Heat Exchanger -

using the high

pressure hose, traverse the exposed top and side of

the heat exchanger angling the sump to drain.

13.3.2

Should a high pressure hose not be available,

the respective heat exchanger will have to be

removed from the aluminium casing after isolating

from the flow and return water pipework. This

involves drain down and the removal of all fittings

from the rear of the boiler, secured by M8 nuts and

washers – see Figure 10.4.

Note

, there is an ‘O’ ring

used on each fitting.

Each module holds approximately 4 - 5 litres of water

and weighs 50 - 60kg (depending on model). It is

strongly recommended

that a minimum of two

people are on hand to lift the module from the wall.

Alternatively, two lifting eyes are provided for use with

suitable lifting equipment.

13.3.3

Carefully place the module onto two blocks

of wood so that the heat exchanger front casting

is supported off the floor to protect from damage.

Remove the 4xM10 nuts securing the front casting to

the aluminium casing and carefully lift the casing

vertically upwards away from the heat exchanger.

Unhook the stainless steel springs and remove the

16 stainless steel baffle plates to expose the finned

tube bank. Wire brush both sides of the baffles to

remove any deposits.

Thoroughly wire brush the finned tubes.

13.3.5

Re assemble in reverse order and refit heat

exchanger to the casing using a new gasket. Replace

the water connection gaskets on the rear of the

boiler. Re-connect the water connections using new

‘O’ rings. Carefully lift the module back onto the wall

plate and secure with the M10 nut and bolt on the left

hand side mounting. Re-fit the system pipework and

check for soundness.

29

Summary of Contents for Sherborne S65

Page 8: ...HAMWORTHY HEATING LTD SHERBORNE 500001103 E Figure 1 1 Boiler Installation Typical 2 ...

Page 29: ...HAMWORTHY HEATING LTD SHERBORNE 500001103 E Figure 10 6 Gas Pipe Fitting 23 ...

Page 45: ...HAMWORTHY HEATING LTD SHERBORNE 500001103 E NOTES 39 ...

Page 46: ...HAMWORTHY HEATING LTD SHERBORNE 500001103 E NOTES 40 ...

Page 47: ...Notes ...