HAMWORTHY HEATING LTD

5

SPETISBURY

500001118/C

6.0 FLUE SYSTEM

6.1 General Requirements

Detailed recommendations for flue systems are given in

BS 6644

,

IGE/UP/10,

"Flues for Commercial and

Industrial Gas-Fired Boilers and Air Heaters."

The following notes are intended to give general

guidance only.

The flue passages within the Spetisbury operate

under pressurised conditions and in order to

eliminate any additional resistance, it is

recommended that the flue system shall be adapted

to its design diameter as soon as possible, after

leaving the boiler.

The boiler should be connected to a single flue

system in the case of a single boiler, or a common

flue header in the case of a multiple boiler

installation. Flue systems must be self supporting,

contain access for cleaning and contain a

maintenance joint near the boiler outlet to allow for

removal of the flue box during servicing.

Spetisbury boilers are suitable for installation in a

balanced compartment in accordance with the

requirements of

BS 6644.

Consult Hamworthy

Heating Technical Department for help or

assistance if in doubt.

6.2

Design Waste Gas Volume and Temperature

It is recommended that the volume and temperature

of the waste gases used for design of the flue

system are as shown in Figure 15.7.

6.3 Materials

Materials used for the flue system must be mechanically

robust, resistant to internal and external corrosion, non-

combustible and durable under the conditions to which

they are likely to be subjected.

Consideration should be given to possible freezing of

condense water traps and pipework. This must be

avoided at all times. Insulate condense pipes if freezing

temperatures are likely to be encountered.

Chimneys should be lined with a non-porous acid-

resistant material in accordance with BS.5854, e.g.

a flexible flue liner or similar British Gas Approved

material. The internal diameter of the liner must not

be less than the recommended flue size and the

number of joints should be kept to a minimum.

Any joint between the flexible liner and the flue pipe

from the boiler should be made using a purpose

made connector. Existing chimneys should be

thoroughly swept before use and any register plates,

dampers, or restrictions removed.

If the boiler(s) is not connected to a chimney

system, but is connected directly to outside by a

standard stainless steel flue (either single or twin

wall) it is particularly important to ensure that the

point at which it exits the building is fully

weatherproofed.

6.4 Suction

The flue system should be designed to maintain

atmospheric pressure or a slight suction at the boiler

flue connection at all times (0.1 - 0.3mbar). It is

recommended that a draught stabiliser is fitted to the

flue system where the suction is likely to exceed

0.3mbar.

6.5

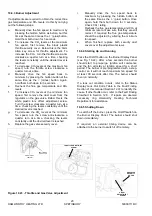

Disconnection

Provisions should be made for disconnection of the flue

pipe for servicing. It is advisable that bends are fitted

with removable covers for inspection and cleaning as

appropriate.

NOTE!

The flue system must be self

supporting and not present a risk to people in or around

the building.

See

Section 13:

SERVICING

for further information

.

6.6 Flue Discharge

The flue system must ensure safe and efficient

operation of the boiler to which it is attached, protect the

combustion process from wind effects and disperse the

products of combustion to the external air.

The flue must terminate in a freely exposed position and

be situated so as to prevent the products of combustion

entering any opening in a building. Consideration should

be given to the fitting of a flue discharge terminal or grille

to stop the ingress of birds etc.

The flue system should be designed such that the

flue terminates at least 1 metre above the roof

surface, or above the level of any nearby structure

which is within 2.5 metres of the flue.

6.7 Surface Temperatures

Combustible materials in the vicinity of the boiler and

flue shall not exceed 65 °C during boiler operation. The

flue shall not be closer than 50mm to any combustible

material, except where it passes through such material

with a non-combustible sleeve when the air gap may

not be less than 25mm.

6.8

Flue System Location

The flue system must not be placed or fitted where

there is undue risk of accidental damage to the flue pipe

or undue danger to persons in the vicinity.

NOTE!

The

flue

MUST

be self supporting. Check that the flue and

chimney are clear from any obstruction.

6.9 Condensate Discharge

When designing the flue system, care must be taken

to ensure that any condensate which may form

within the system, can be safely drained to a

suitable waste point and, that the flue material used

is resistant to the corrosive effects of that

condensate.