HAMWORTHY HEATING LTD

7

SPETISBURY

500001118/C

Where the system is operating on a DT of 20°C, care

should be taken to ensure that the return temperature

does not fall below 50°C.

8.9.2 Water Flow Controls

Any external mixing valve/shunt pump or similar

controls should

ALWAYS ENSURE

that the minimum

water flow rate as shown in Figure 3.1 is maintained.

8.9.3 Frost Protection

Consideration should be given to fitting a frost

thermostat set at approximately 4°C.

8.10 Unvented Systems

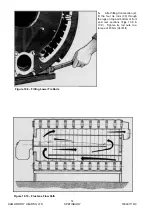

See Figure 15.1 for typical layout of a Unvented

(Pressurised) Hot Water System. For system design

refer to

BS 7074 Part 2.

In order to correctly size a pressurisation unit for any

heating system certain parameters are required. These

are:-

1)

Static height of highest component in system

(metres).

2)

System volume - if it is not known a general rule of

thumb of 10 litres/kW of installed boiler power can be

used.

3)

Maximum flow temperature (°C).

4)

Maximum system hot working pressure, generally

given in bar g.

From the above information Hamworthy Heating can

size the pressurization unit and also the expansion

vessel required. Care must be taken in sizing expansion

vessels to ensure maximum acceptance factors are not

exceeded. Normally manufacturers of vessels impose

a limit of 0.5. This value must not be exceeded at any

time during the operation of the boiler: this includes the

over pressure condition should a safety valve lift.

Consideration should also be given to sizing of the

safety valve(s) in the system. See

BS 6759

: Part 1, for

information. See also

BS 6880

: Part 1 for design

considerations.

8.11 Modular Boiler Control Schemes

For modular boiler installations, Hamworthy Heating

can supply a unique boiler management control system

called the ‘Marshall HE’. This system comprises: a wall

mounted master control unit, which houses the main

interface processor and will control up to 8 stages. For

further information, contact Hamworthy Heating for

details.

8.5 Thermometer

See Figure 15.1 for typical position.

A thermometer complete with pocket should be fitted in

the pipework to indicate water flow temperature.

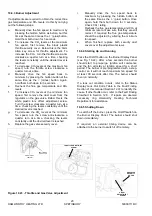

8.6 Drain Valves

Each boiler should have ¾” NB drain valve fitted (not

HHL supply), to drain the boiler only. A plugged Rc ¾”

connection is provided for a drain valve at the bottom of

the front boiler section. The heating system in total

should have drain valves as recommended by

BS

6644

. See Figure 15.1 for recommended positions.

8.7 Circulating Pump

One or more circulating pumps will be required to

circulate water around the boilers and heating system.

The pump should be sited to facilitate servicing. It is also

important that the existing system be flushed through

twice to remove any loose matter, which may have

accumulated. If in any doubt regarding the cleanliness

of the system, a coarse filter should be fitted in the

return pipework to the boilers.

NOTE:

If boilers are run off time clock control, a pump

overrun (not HHL supply) should be fitted which must

run for a minimum of 5 minutes on shut-down of the last

boiler.

8.8 Minimum Water Flow Rates

Minimum water flow rates are shown in Figure 3.1.

These flow rates should be maintained through the

boiler at all times whilst the boiler is firing. If the

water flow rate is allowed to fall below the minimum,

the boiler heat exchanger could fail due to the

resultant scale formation. Particular attention should

be paid to the restriction of external flow circuits

during periods of low heat demand.

8.9 Control Schemes

8.9.1 Temperature Controls

An adjustable control thermostat is supplied with each

boiler and should be set to operate within the range 65-

90°C for standard applications. A temperature limiter,

(hand reset limit thermostat) is also fitted to the boiler

and must be set at 100°C.

NOTE!

The minimum difference between control

thermostat and temperature limiter

must never

be less

than 10°C.

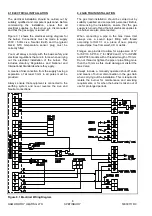

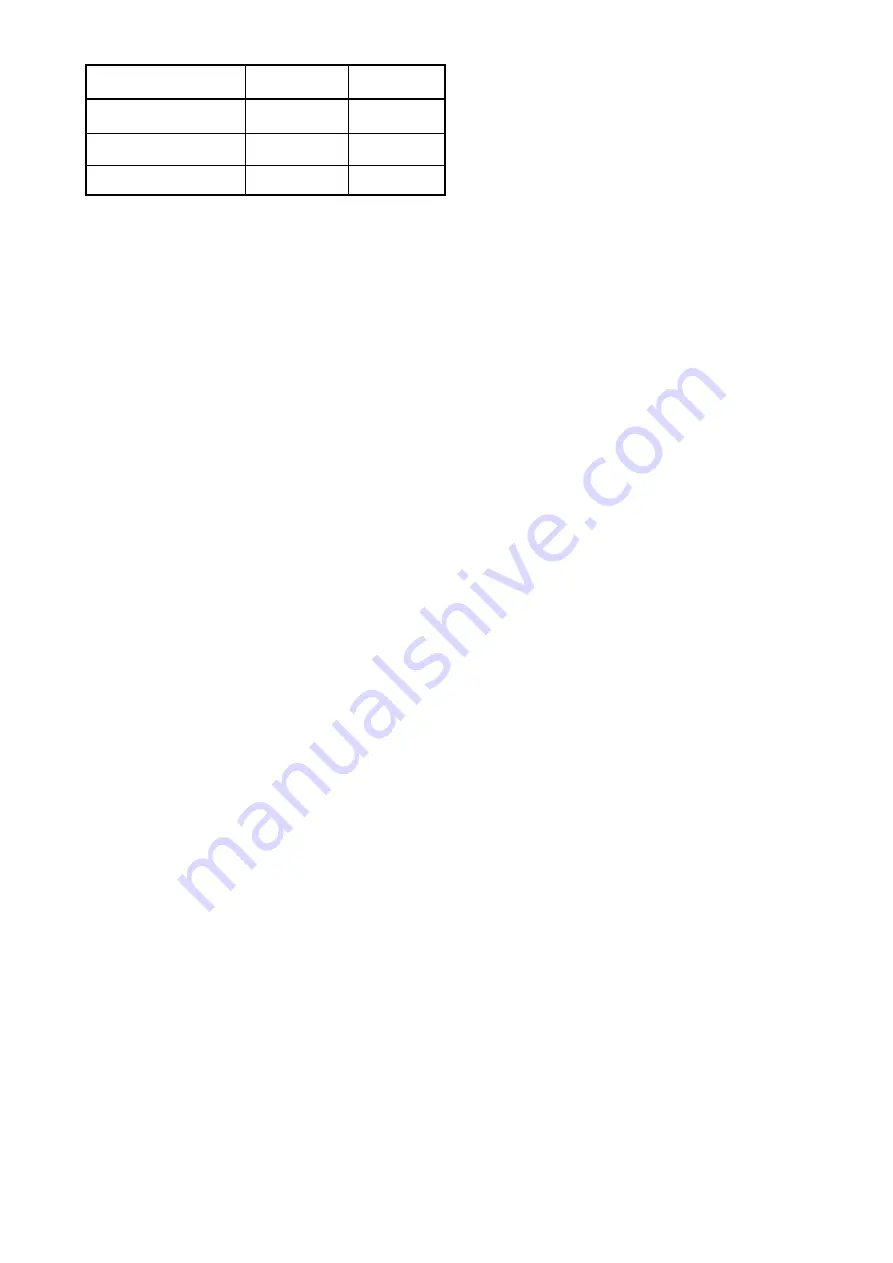

Boiler Output

Feed

Vent

60kW - 150kW

25

32

150kW – 300kW

32

38

300kW – 600kW

38

50

Figure 8.3. Cold Feed and Vent Pipe Sizes (mm)