LB

II

-PLUS Technical Manual

14

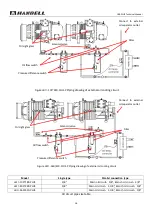

The compressor is equipped with a suction filter, it is still suggested to install a suction filter on the suction pipe

and clean it regularly, so that it is convenient for cleaning and replacement, with double protection at the same time.

When the system starts to operate, if the pressure drop is found greater than 0.5bar, please clean up filter. If the filter

is found damaged, we need to replace it in time, and clean up the impurities in the pipeline. During installation,

please ensure the correct direction of the filter. The stop valve is suggested to be added at the inlet and outlet for

easy maintenance.

2.3.2

External oil circuit system

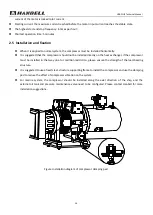

If the compressor operates under low temperature conditions and the lubricating oil does not have extra cooling,

it will be unable to meet the operation requirements because of the high oil temperature. At this time, it is suggested

to configure the external oil cooler which can reduce the discharge temperature, and can also prolong the life-time of

the system.

Note:

The temperature of the inlet oil should not be higher than 60

℃

.

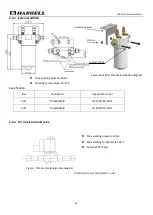

There are mainly 3 type of oil cooling system:

Air cooling type

Water cooling type

Refrigerant cooling type

The heat exchange data of the oil cooler can be obtained by the HANBELL model selection program. The limit

operating conditions should be taken into account, such as the maximum pressure difference (high condensation

temperature and low evaporation temperature).

x x x

Detail 2

Detail 3