LB

II

-PLUS Technical Manual

23

NEMA declares that when the voltage imbalance of the motor terminal is not more than 1%, the multiphase

motor can be successfully opened to operating state at rated startup. But it is not allowed to start the motor when

the voltage unbalance is more than 5%, which will damage the motor. It is suggested to install an extra high and low

voltage protector at the place where the voltage is unstable. Set the rated voltage range within ±5%, to ensure the

safe and long-term operation of the compressor.

It is suggested that if the difference of the maximum and minimum phase current is bigger than 3% of the

average current during operation, the three-phase power lines can be exchanged as shown in following figures. If the

unbalanced phase does not change with phase modulation, it's not the motor problem. Please turn off the machine

in time and wait the problem to be solved. If it is motor problem, please contact HANBELL.

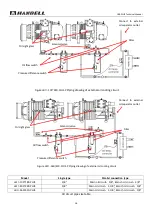

Standard connection of main power supply line Main power supply line connection during test

2.4.3

Electromagnetic contactor selection

Please refer to the section of contactor in the electrician manual. It is recommended to refer to the AC3

specifications, and to choose the suitable contactor according to the data and the system design.

Suggestions

1.

The set value of the conventional electronic leakage protector should be higher than 50mA (recommend

25mA for moist area).

2.

The grounding resistance should not exceed 500Ω.

3.

If the electronic leakage protector alarm, please check whether the insulation device is normal and its line

setting is correct or not.

4.

Please select the appropriate AC contactor, air switch, and power line according to the maximum operating

current in below table.

2.4.4

Compressor electrical specification table

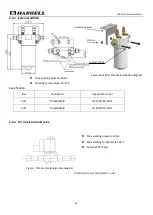

Table-4 Compressor motor technical data (Power: 380V/50Hz)

Mode

LB

II

-

100(-P)

LB

II

-

140(-P)

LB

II

-

180(-P)

LB

II

-

200(-P)

LB

II

-

230(-P)

LB

II

-

250(-P)

LB

II

-

280(-P)

LB

II

-

360-P

LB

II

-

410-P

Locked rotor current

LRA

(

A

)

218

310

370

508

565

565

710

780

1020

Maximum working current

MCC

(

A

)

57

78

94

114

127

138

151

203

232

KM1, KM2 contactor

(

A

)

40

50

65

90

95

95

115

150

150

Wire selection

(

mm2

)

6

10

16

25

25

35

35

50

50

Locked rotor current: the motor rotor fails to rotate because of heavy load or other reasons, and at this time the

Z

X

Y

7

8

9

U

V

W

1

2

3

Z

X

Y

8

9

7

U

V

W

2

3

1