LB

II

-PLUS Technical Manual

39

lubricating oil foam will disappear when the compressor works under the rated condition. In general, the

normal oil level in the oil separator shall be above the middle level of the low oil level sight glass, and the

minimum level shall not be lower than the middle level of the low oil level sight glass, otherwise it means

insufficient oil filling or compressor oil losing.

The operating conditions should be adjusted according to the following way: the discharge temperature

should be over 30K than that of condensing temperature, and the over-heat of the suction is within 15K.

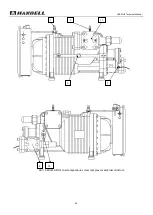

The whole equipment, especially the pipe, must pass the abnormal vibration test. If there is abnormal

vibration or noise during the operation of the compressor, please contact HANBELL.

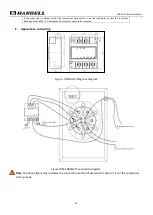

If the compressor is in long-time operation, the following items should be checked daily: machine operation

data (such as: three-phase voltage, line current etc.), the oil temperature and oil level of the lubricant, all

sensing parts, the connecting and fastening of the wire, and the sight line of the oil circuit.

When the condensing unit is in operation, special attention should be paid to its auxiliary equipment, as

well as the maintenance schedule of the unit after the first start operation.

To ensure normal viscosity of the lubricating oil at low ambient temperature and ensure smooth lubrication

of the bearing, it is recommended that the oil heater on the external oil separator should be kept open

when the compressor is shut down, so as to prepare for the next start.

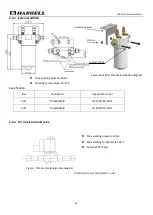

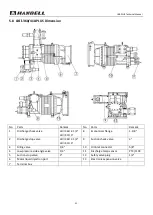

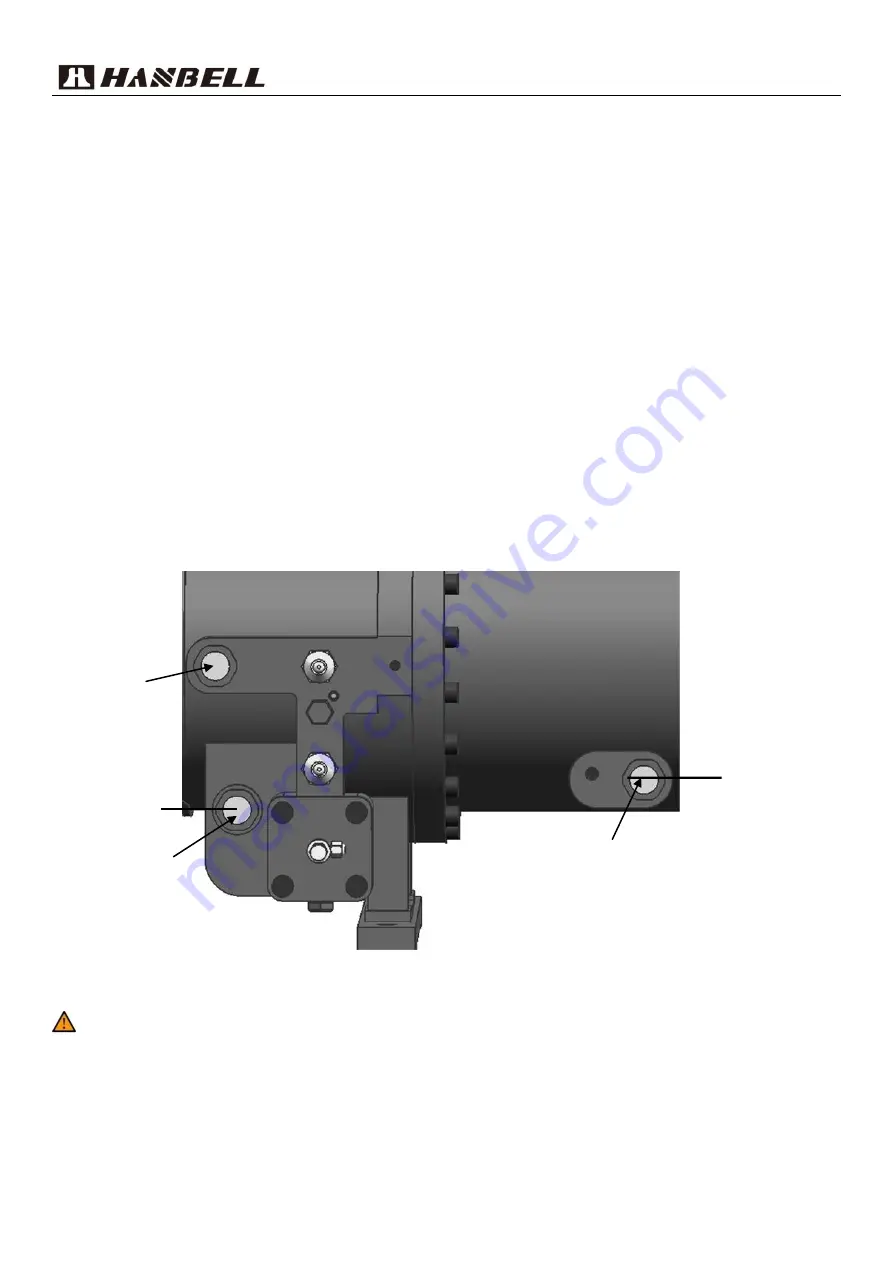

Figure - Compressor oil level mark

Note:

When compressor is running, the oil level needs to be between the middle line of the high oil sight glass and the

low oil sight glass. Through the sight glass, the flow of lubricating oil can be seen and the oil is clear and transparent.

If the oil level is lower than the low oil level sight glass, it is necessary to shut down and refuel. Please check whether

the suction is with liquid or not (oil return shows white or a large number of bubbles occurs), because it will lead to

the sharply increase of oil losing of oil separator, which finally causes the compressor to lose oil.

Sight glass

High oil level

Oil circuit

sight glass

Sight glass

Low oil level

Min

Max