LB

II

-PLUS Technical Manual

7

2.

Application

2.1 Compressor application

Motor cooling

The normal screw refrigeration compressor cool the motor through suction. When it works at low temperature

condition, the mass flow rate of refrigerant is very small. Refrigerant absorbs heat through the motor, resulting in a

lot of harmful superheat, which increases the specific volume of the refrigerant and leads to theloss of refrigerating

capacity.

The LB

II

-PLUS series compressor adopts independent motor cooling. The motor chamber and the compression

chamber are isolated, and only small amount of liquid refrigerant is used to cool the motor, which enables the motor

to work in the ideal temperature range. Meanwhile, it can prolong the life-time of motor. The gaseous refrigerant

after cooling the motor enters the compression chamber to avoid the refrigerating loss caused by the motor cooling.

The effect is particularly obvious at low temperature.

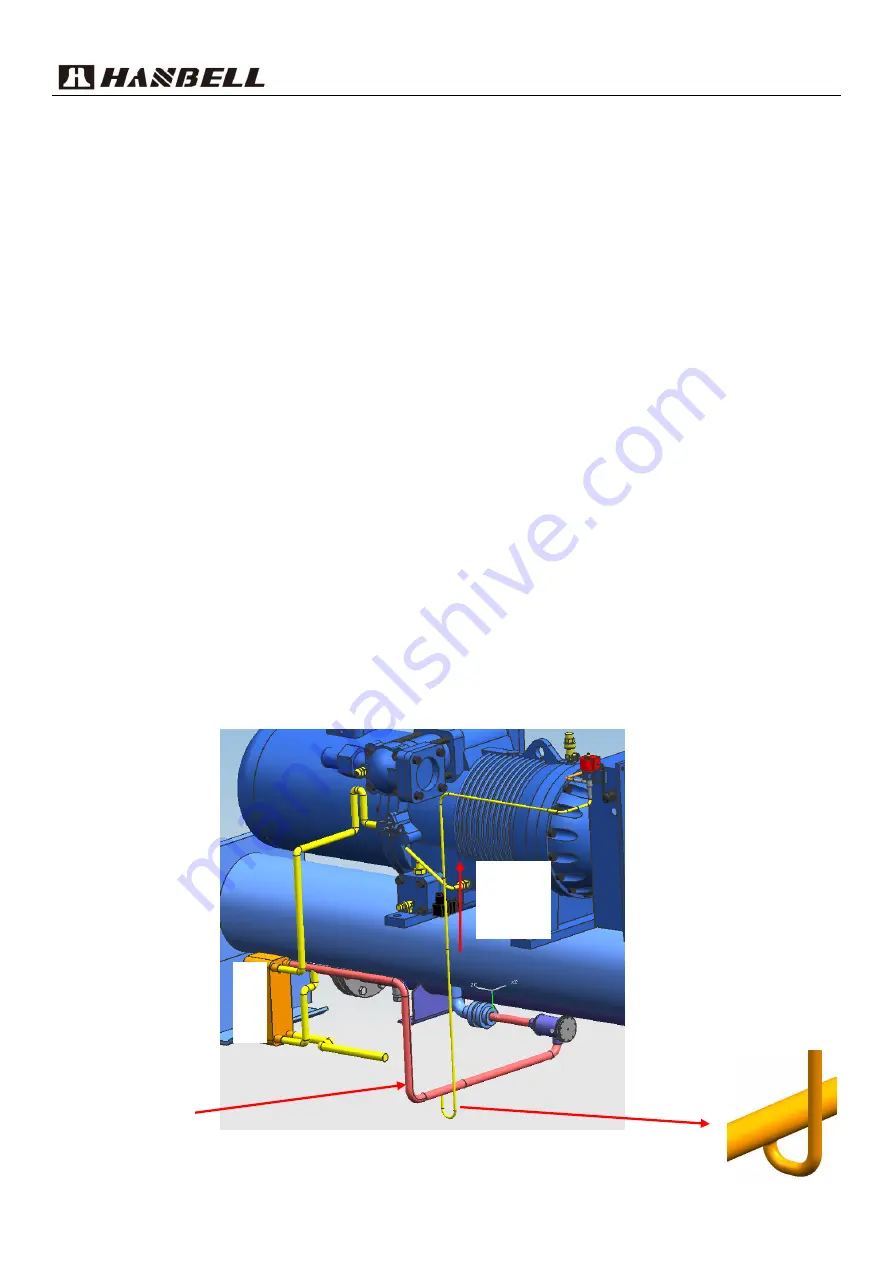

In order to effectively control the refrigerant quantity that enter into the motor chamber, HANBELL designed the

scheme to control the motor liquid injection:

Electronic expansion valve specially designed for LB

II

-PLUS

With electronic expansion valve to control the temperature of the motor is shown in the following Figure, the

solenoid valve and the compressor start or stop at the same time. The electronic expansion valve is controlled by

controller of LB

II

-PLUS. Through a special algorithm, the temperature of the motor is controlled at around 60

℃

.

The following are description of two types of injection points:

1)

The liquid taking point of the

motor liquid injection shall be

taken at the front and bottom

of the rising riser of main

liquid pipe

The main liquid pipe

is required to use

riser Piping after the

motor takes the liquid

point, so as to ensure

that when the system

is short of refrigerant,

there is still enough

liquid refrigerant to

cool the motor.

Motor

liquid

injection

E

C

O