LB

II

-PLUS Technical Manual

38

4.

Maintenance

4.1

Items to be checked before machine starting

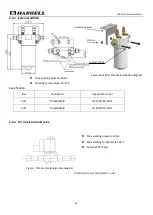

Item

Key points to be checked

Corresponding confirmation method

1. Compressor and

spare part

appearance check

1.Refrigerant oil level;

2.Lubricant oil temperature;

3. Stop valve completely open;

4.Motor liquid injection angle

valve completely open

1. High oil level is full;

2. Before trial operation, the oil need to be heated to

around 40

℃

, the time required for heating is about 8 hours;

3. Open the stop valve dustproof nut to check;

4. Open the motor injection valve dustproof nut to check;

2. Electrical system

1. Main power supply voltage

value

2. Control circuit voltage value

3.

Inter-phase

and

ground

insulation resistance of motor

4. Connection between power

and wire

5. Grounding wire installation

6. Switch, sensor, and controller

setting

1. The voltage fluctuation range of the main power supply is

controlled within the rated voltage 380V±5%, and the

instantaneous voltage drop is less than 10% when it starts;

2. The standard voltage of the control circuit is 220V±10%; if

there are other requirements, please contact Hanbell;

3. Insulation value shall be higher than 5MΩ;

4. The power supply is connected to the terminal box with

good insulation. The power line should be far away from the

heat source and the metal with angular angle, so as to avoid

the damage of the insulation skin. It should be equipped

with a terminal box and bolt;

5.Make sure it is installed;

3. Pipeline system

1. Whether the pipe is secured or

not;

2. Make sure no leakage on the

pipe

1. Visual check or manual check

2. Check with a leak detector or soapy water, especially at

the welding area and interface.

4. Protection

device

1. Coil temp protection

2. Discharge temp protection

3. Oil level switch

1. Not activated(closed circuit)

2. Not activated(closed circuit)

3. Full oil level(closed circuit)

Table - Items to be checked before machine starting

4.2

Items to be checked during operation

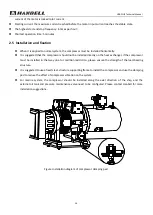

Power on the compressor for about 0.5-1 seconds to determine whether the compressor rotation is normal

or not by monitoring the suction and discharge pressure (the normal rotation of the compressor: the

suction pressure drops immediately and the discharge pressure rises).

After starting, check the lubricating oil in the sight glass on the external oil line to find out whether it is full

or not. If you find any problems, please check the pressure difference between the high and low pressure,

check if the filter is blocked or not (pressure difference alarm), whether the oil return solenoid valve of the

external oil separator is open or not, if the oil outlet is blocked or not, check whether the motor

temperature rise too fast, whether spray liquid pipe supplies liquid or not.

When the compressor starts, the lubricating oil in the oil separator will produce foam in short time, but the