LT-S-(L) Technical manual

3

)

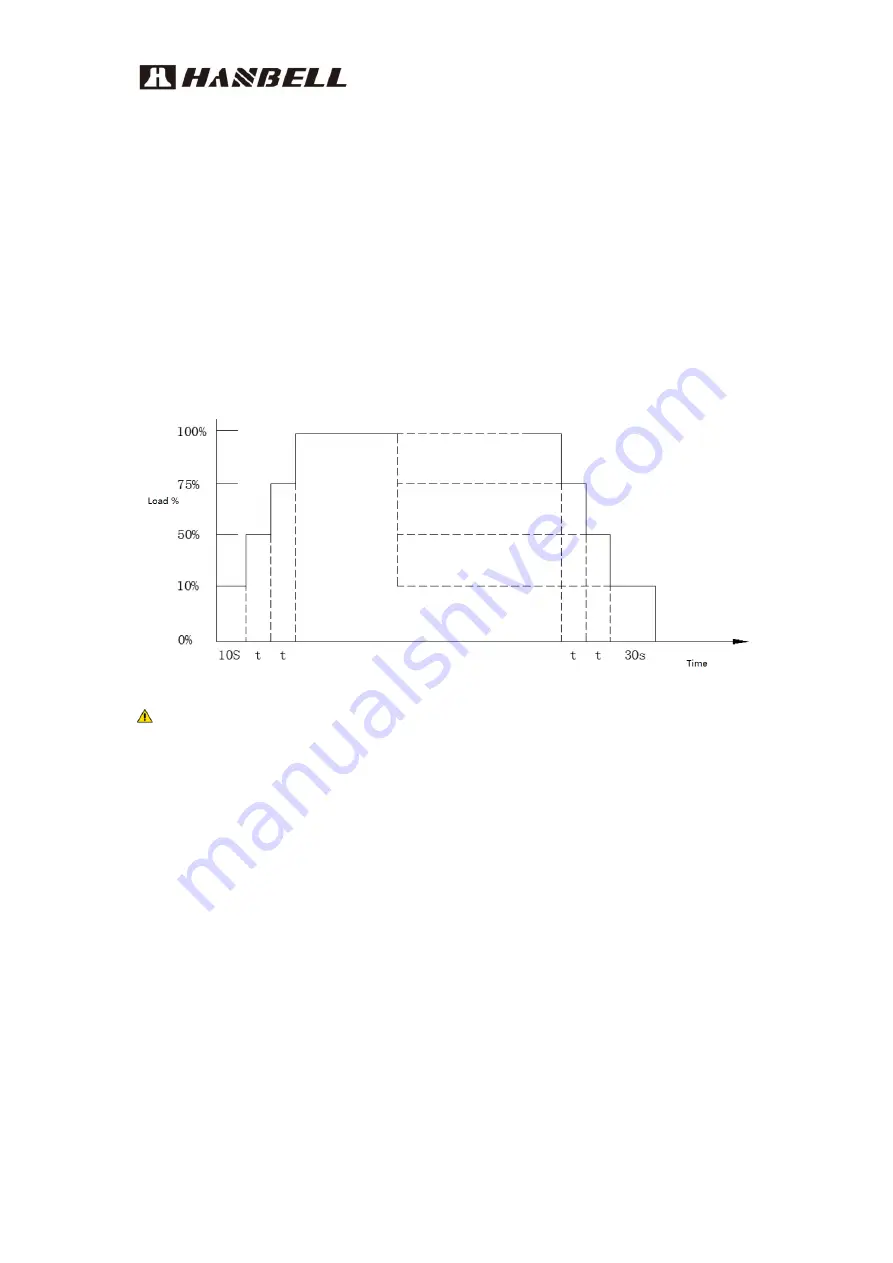

Compressor unloading for startup, and stop

To decrease the mechanical loading to compressor’s parts and

decrease the starting

current during start up. Hanbell designs for LT compressor the function of unloading

startup. To ensure compressor loads steadily, please follow Figure 3-16 to load step by

step during the whole loading process.

When compressor is about to shut down, it is also required to unload to ensure that

the slide valve is at lowest loading position during next startup and compressor could

have an unloading startup. Thus Hanbell requires no matter what load condition of the

compressor is, it should be unloaded step by step till minimum load before stop

according to below Figure 3-16.

Figure 3-16. Compressor Startup and Stop Process

Caution

:

1

)

After startup, keep the minimum load for 10 seconds. Before shut down, keep the

minimum load for 30 seconds(Time can be set to 10~60seconds).

2

)

After startup, when the pressure difference between high pressure and middle

pressure is less than 3.5bar, the compressor shall be run at 10% load at low

pressure stage. Don't load and open ECO.

3

)

t=30 seconds(Time can be set to 30~60seconds).

4

)

After the compressor shut down, the SV1 (unload) & SV2(10%) need to be still

energized for 3 minutes, so as to ensure the compressor can still at min load

position at next startup.

5

)

Hanbell strongly recommends that the compressor start-up and shutdown control

logic shall refer to above graph. For detail information

please refer to the regulations written in LT-S Control Requirements.