LT-S-L Technical manual

5.

System Application

★

Note

:

Please consult Hanbell for parallel application and heat pump

application.

5.1

Piping Design

5.1.1

Suction and Discharge Piping Layout

1

)

Material and structure of suction and discharge pipe

The vibration of the compressor is small in normal operation, so it is not

necessary to use flexible joints for suction and discharge tubes, but the pipes need to

have enough flexible length to ensure the suction and discharge pipes won't cause any

stress to the compressor. It is recommended to use copper tube for the suction and

discharge piping in order to decrease the piping vibration when the compressor is in

operation.

2

)

The dimensions of suction and discharge piping:

It is suggested to design the dimension of suction and discharge piping according

to Hanbell recommendation (refer to 10.2.2).

3

)

Piping for parallel system

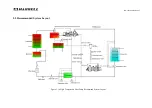

To improve the system operation efficiency, it’s necessary to reduce the gas-flow

resistance and consider the oil return of suction piping. The recommended piping of

suction and discharge side for parallel system is shown below:

Be aware of the area of the main pipe should not be less than the area of the other

pipes to make sure the pressure drops could be controlled in reasonable range.

Piping at discharge side

Figure 5-1. Discharge Piping for Parallel System

Piping at suction side

x x x

Detail drawing1