LT-S-(L) Technical manual

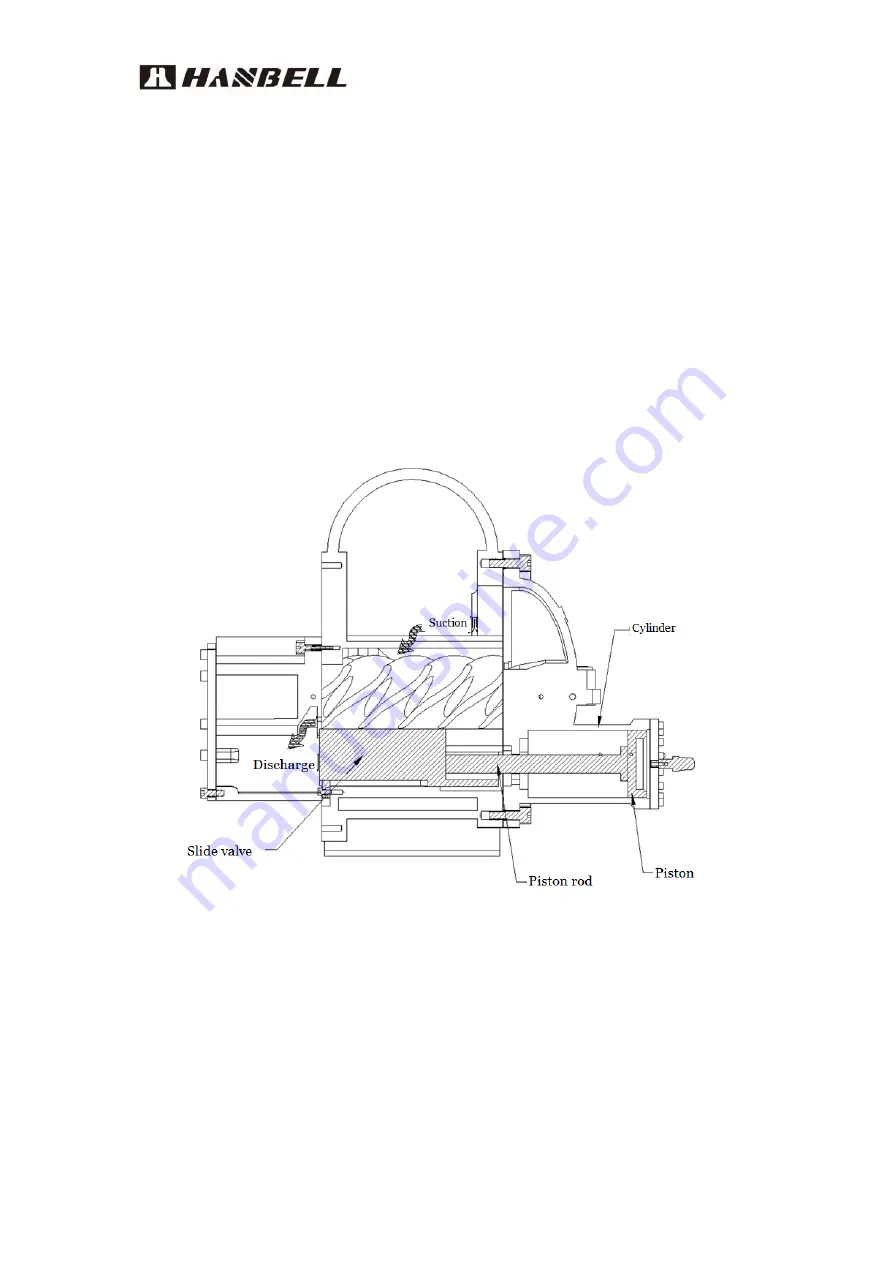

sides of the piston. As a result, the piston can be controlled by discharging the high

pressure lubricant at one side to low pressure, letting it flow to the low pressure side

so that the slide valve will move with the piston to realize the loading and unloading

of the compressor.

The purpose of the piston spring is to push the piston to its initial position (min.

load position), so as to realize the automatic unloading start. It not only reduces the

mechanical impact on the compressor's moving parts, but also reduces the electrical

current during compressor start up.

Stepless capacity control, solenoid valve(SV1:unloading, SV3:50%, SV5:100%)

is controlled by a micro controller or a thermal switch to adjust the piston smoothly to

stably control cold output. If the oil filter capillary or solenoid valve of the capacity

modulation system don't work properly, it will cause the capacity modulation system

to be abnormal and fail.

Figure 3-1.Capacity Modulation System